13.4Automatic Operation Restart with BLOCK RESTART Condition

X=100, Y=70, Z=10.

3rd part block: Hole machining and retraction to start position (G98) or to

At the end of all three part blocks the control stops in single block mode. If the canned cycle is programmed with repetition count L the above part blocks are repeated.

2nd case: Interrupting and restarting canned cycle in the course of positioning in the selected plane

If in the sample cycle the movement is interrupted during moving to position X=100, Y=70 and it is moved to the start position of the block by means of the BLOCK RESTART ![]()

![]()

![]()

condition (to coordinate X=50, Y=20, Z=10 in the above example) the movement may be led back to the 1st case.

3rd case: Interrupting and restarting canned cycle in the course of positioning to point R

If in the sample cycle the movement is interrupted during positioning to point R=2 along axis Z and it is moved to the start position of the block by means of BLOCK RESTART ![]()

![]()

![]()

condition (to coordinate X=100, Y=70, Z=10 in the above example) the movement may also be led back to the 1st case.

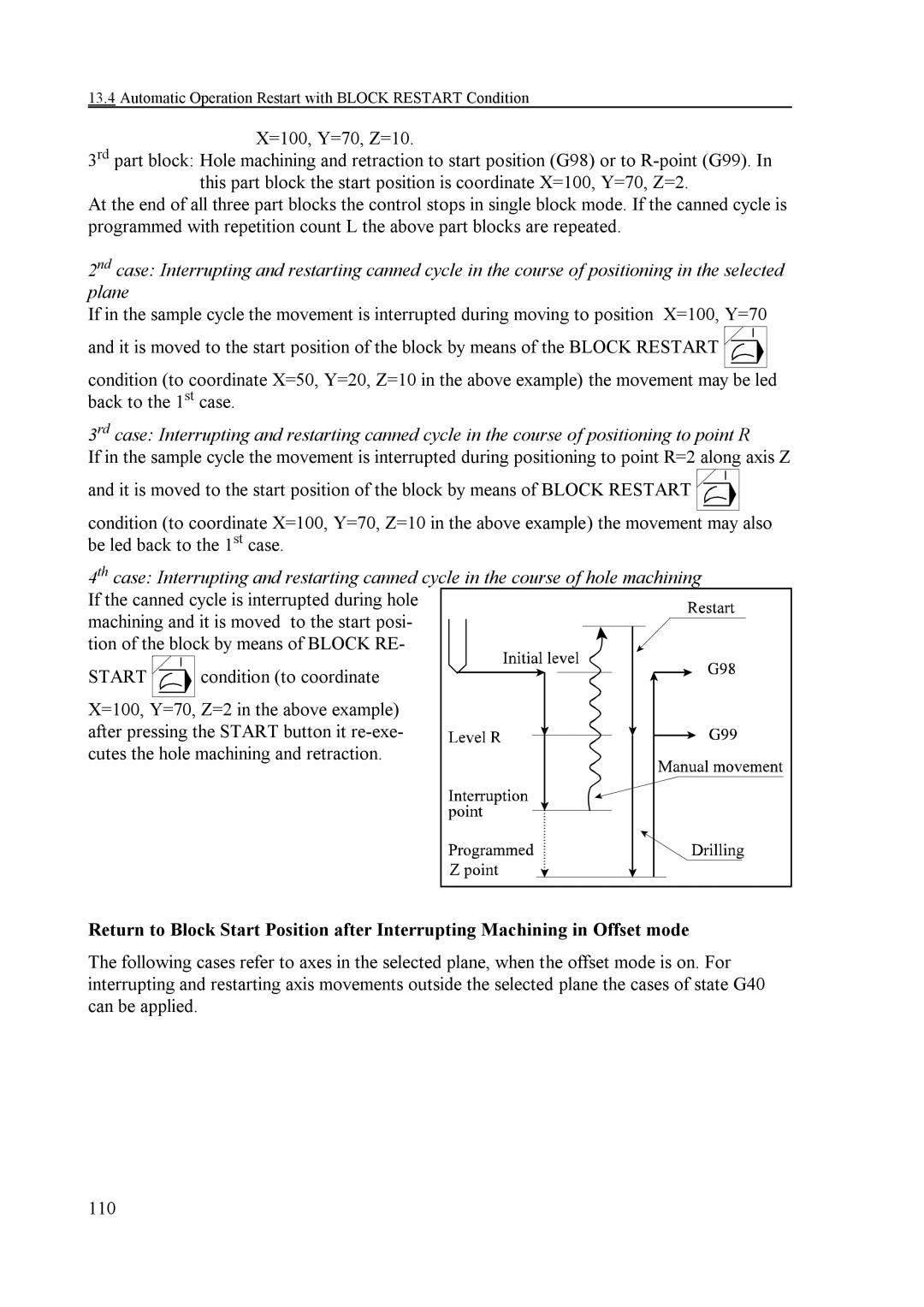

4th case: Interrupting and restarting canned cycle in the course of hole machining If the canned cycle is interrupted during hole

machining and it is moved to the start posi- tion of the block by means of BLOCK RE-

START ![]()

![]()

![]() condition (to coordinate

condition (to coordinate

X=100, Y=70, Z=2 in the above example) after pressing the START button it

Return to Block Start Position after Interrupting Machining in Offset mode

The following cases refer to axes in the selected plane, when the offset mode is on. For interrupting and restarting axis movements outside the selected plane the cases of state G40 can be applied.

110