13.4Automatic Operation Restart with BLOCK RESTART Condition

13.4.3Cases of Return by Means of BLOCK RESTART Condition

Return to Block Start Position After Interrupting Simple Movement Block

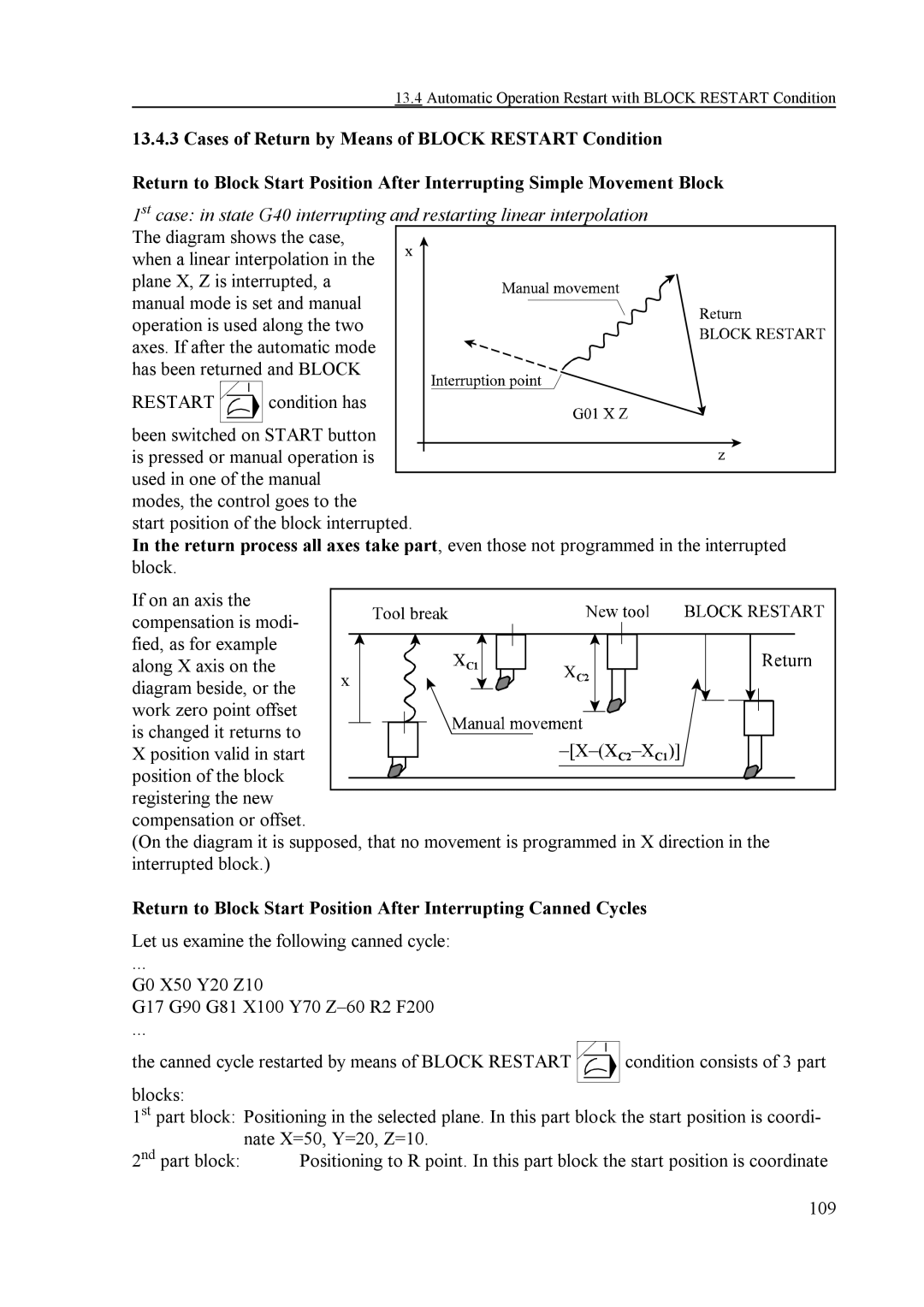

1st case: in state G40 interrupting and restarting linear interpolation The diagram shows the case, ![]()

when a linear interpolation in the

plane X, Z is interrupted, a manual mode is set and manual

operation is used along the two axes. If after the automatic mode

has been returned and BLOCK

RESTART ![]()

![]()

![]() condition has

condition has

been switched on START button

is pressed or manual operation is used in one of the manual

modes, the control goes to the

start position of the block interrupted.

In the return process all axes take part, even those not programmed in the interrupted block.

If on an axis the

compensation is modi- fied, as for example

along X axis on the diagram beside, or the

work zero point offset is changed it returns to

X position valid in start

position of the block registering the new

compensation or offset.

(On the diagram it is supposed, that no movement is programmed in X direction in the interrupted block.)

Return to Block Start Position After Interrupting Canned Cycles

Let us examine the following canned cycle:

...

G0 X50 Y20 Z10

G17 G90 G81 X100 Y70

...

the canned cycle restarted by means of BLOCK RESTART ![]()

![]()

![]() condition consists of 3 part

condition consists of 3 part

blocks:

1st part block: Positioning in the selected plane. In this part block the start position is coordi-

2nd part block: | nate X=50, Y=20, Z=10. |

Positioning to R point. In this part block the start position is coordinate |

109