7.2.2Tool Length Offset Measurement inside the Machine

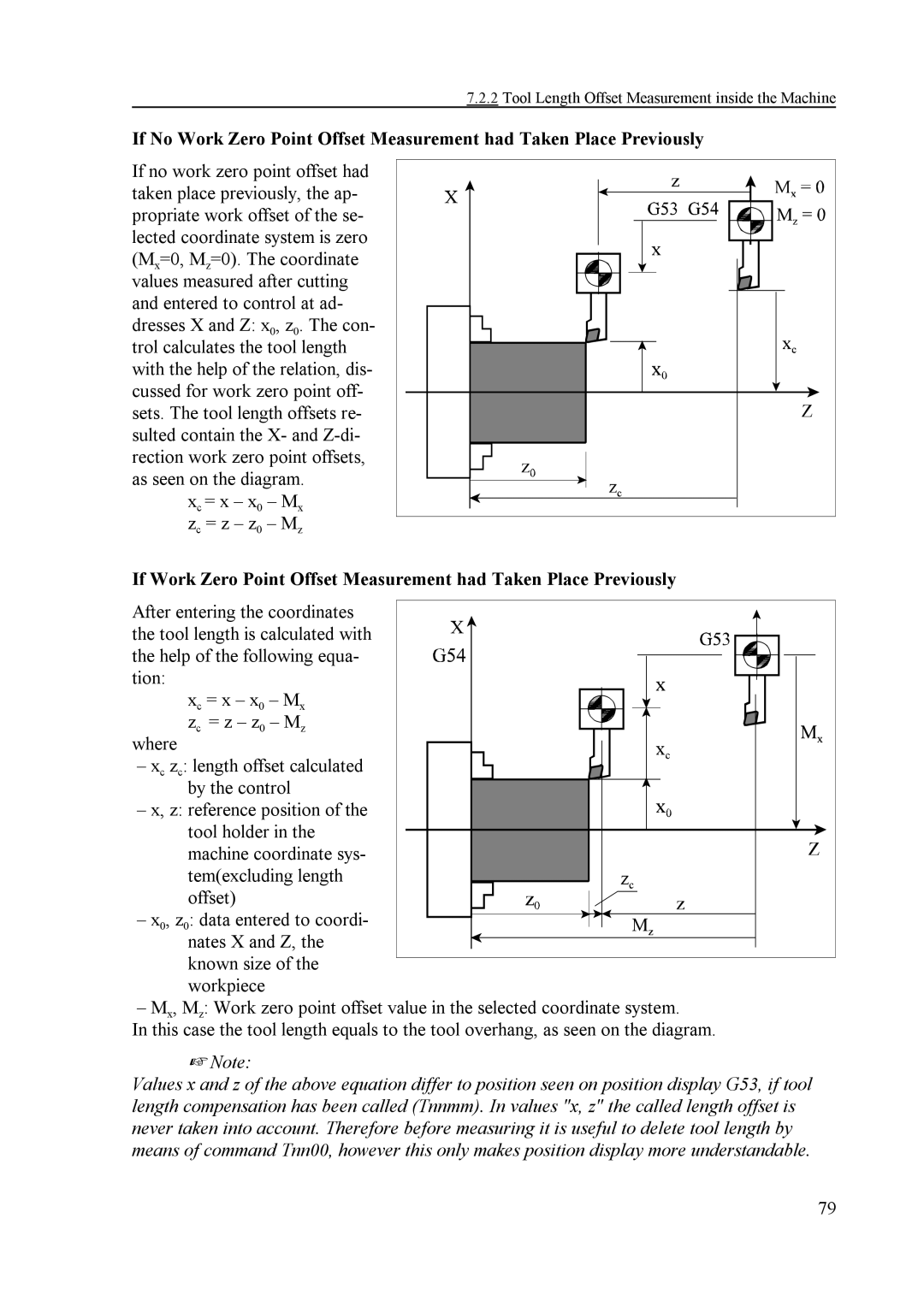

If No Work Zero Point Offset Measurement had Taken Place Previously

If no work zero point offset had taken place previously, the ap- propriate work offset of the se- lected coordinate system is zero (Mx=0, Mz=0). The coordinate values measured after cutting and entered to control at ad- dresses X and Z: x0, z0. The con- trol calculates the tool length with the help of the relation, dis- cussed for work zero point off- sets. The tool length offsets re- sulted contain the X- and

xc = x – x0 – Mx zc = z – z0 – Mz

If Work Zero Point Offset Measurement had Taken Place Previously

After entering the coordinates the tool length is calculated with

the help of the following equa- tion:

xc = x – x0 – Mx

zc = z – z0 – Mz where

– xc zc: length offset calculated by the control

– x, z: reference position of the

tool holder in the machine coordinate sys- tem(excluding length

offset)

– x0, z0: data entered to coordi- nates X and Z, the known size of the

workpiece

– Mx, Mz: Work zero point offset value in the selected coordinate system.

In this case the tool length equals to the tool overhang, as seen on the diagram.

LNote:

Values x and z of the above equation differ to position seen on position display G53, if tool length compensation has been called (Tnnmm). In values "x, z" the called length offset is never taken into account. Therefore before measuring it is useful to delete tool length by means of command Tnn00, however this only makes position display more understandable.

79