8.3 Manual Data Input Mode

8.3 Manual Data Input Mode

Program execution in manual data input mode can only be done upon

If the machine is mounted with NCT machine control board the manual data input mode can be

switched on by pressing the ![]()

![]() button.

button.

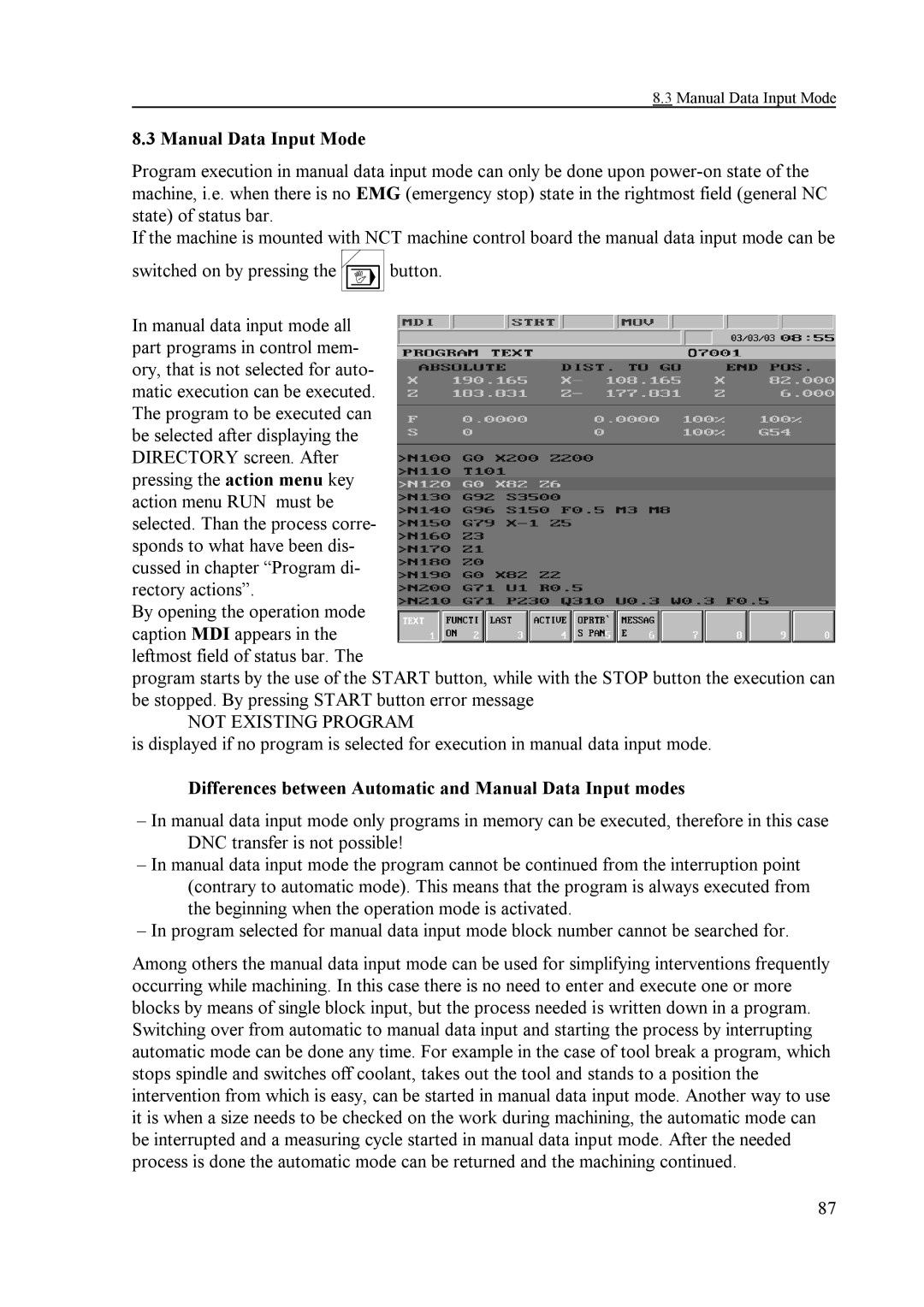

In manual data input mode all part programs in control mem- ory, that is not selected for auto- matic execution can be executed. The program to be executed can be selected after displaying the DIRECTORY screen. After pressing the action menu key action menu RUN must be selected. Than the process corre- sponds to what have been dis- cussed in chapter “Program di- rectory actions”.

By opening the operation mode caption MDI appears in the leftmost field of status bar. The

program starts by the use of the START button, while with the STOP button the execution can be stopped. By pressing START button error message

NOT EXISTING PROGRAM

is displayed if no program is selected for execution in manual data input mode.

Differences between Automatic and Manual Data Input modes

–In manual data input mode only programs in memory can be executed, therefore in this case DNC transfer is not possible!

–In manual data input mode the program cannot be continued from the interruption point (contrary to automatic mode). This means that the program is always executed from the beginning when the operation mode is activated.

–In program selected for manual data input mode block number cannot be searched for.

Among others the manual data input mode can be used for simplifying interventions frequently occurring while machining. In this case there is no need to enter and execute one or more blocks by means of single block input, but the process needed is written down in a program. Switching over from automatic to manual data input and starting the process by interrupting automatic mode can be done any time. For example in the case of tool break a program, which stops spindle and switches off coolant, takes out the tool and stands to a position the intervention from which is easy, can be started in manual data input mode. Another way to use it is when a size needs to be checked on the work during machining, the automatic mode can be interrupted and a measuring cycle started in manual data input mode. After the needed process is done the automatic mode can be returned and the machining continued.

87