7.2.4Calibrating Tool Offset Sensor

Calibrating the Sensor to the Coordinate System of Chuck

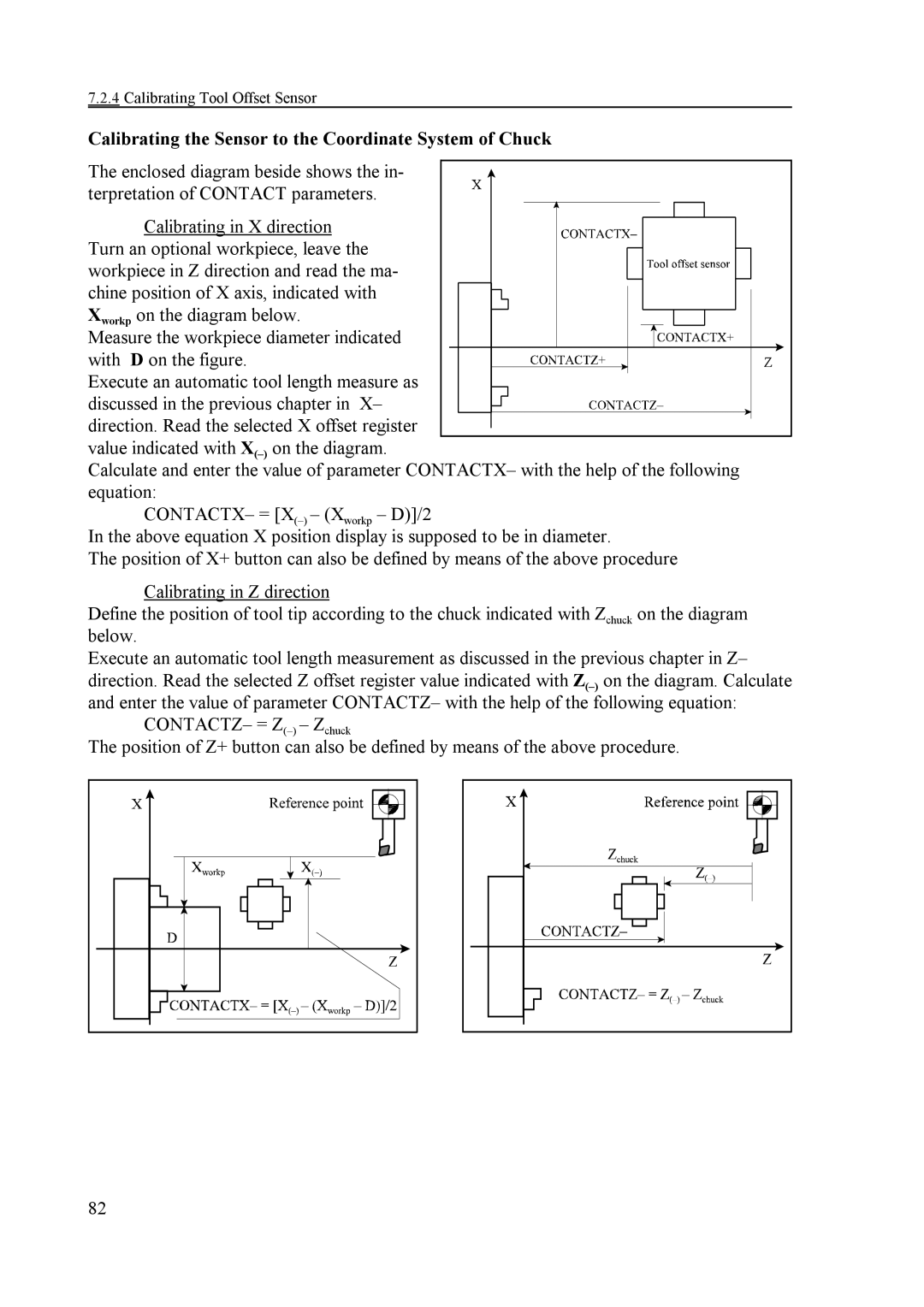

The enclosed diagram beside shows the in- terpretation of CONTACT parameters.

Calibrating in X direction Turn an optional workpiece, leave the

workpiece in Z direction and read the ma- chine position of X axis, indicated with

Xworkp on the diagram below. Measure the workpiece diameter indicated

with D on the figure. Execute an automatic tool length measure as

discussed in the previous chapter in X– direction. Read the selected X offset register

value indicated with

Calculate and enter the value of parameter CONTACTX– with the help of the following equation:

CONTACTX– =

In the above equation X position display is supposed to be in diameter.

The position of X+ button can also be defined by means of the above procedure

Calibrating in Z direction

Define the position of tool tip according to the chuck indicated with Zchuck on the diagram below.

Execute an automatic tool length measurement as discussed in the previous chapter in Z– direction. Read the selected Z offset register value indicated with

CONTACTZ– =

The position of Z+ button can also be defined by means of the above procedure.

82