EN-166

N.B.

N.C.

1.90

|

| LED1 | J61 |

|

| LED2 |

|

| .88 | LED3 | S1 |

|

| LED4 |

|

2 |

| LED5 |

|

|

|

| |

| 0 |

|

|

|

| 0 | 1.80 |

|

|

|

|

|

|

|

|

|

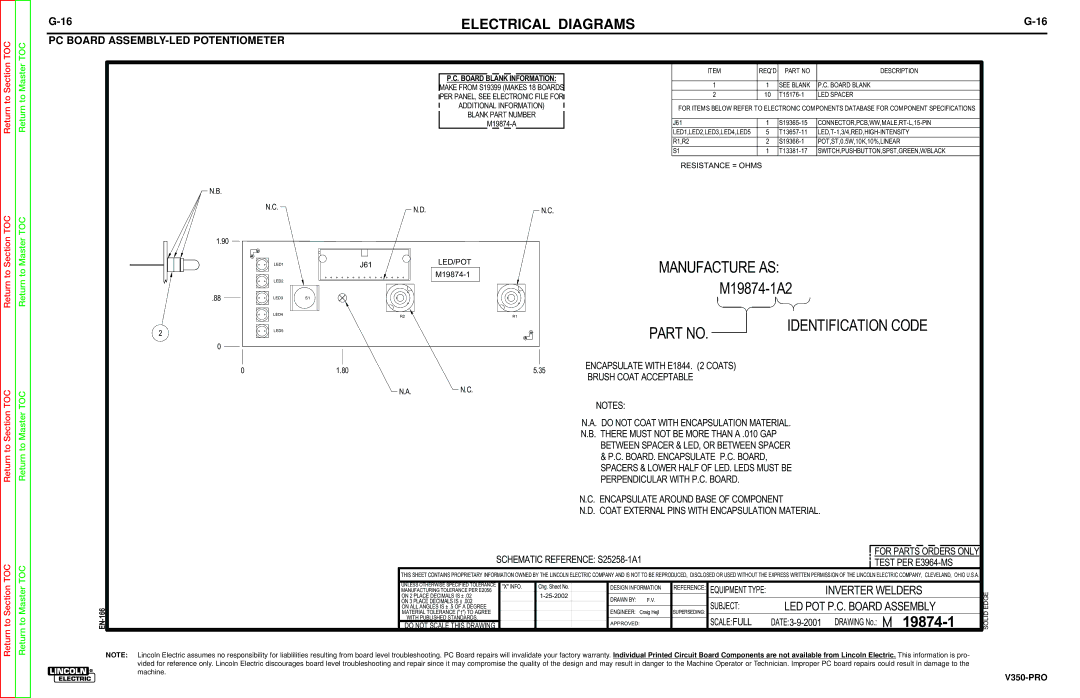

| ITEM | REQ'D | PART NO | DESCRIPTION |

| P.C. BOARD BLANK INFORMATION: |

|

|

|

|

|

| ||||||

|

| 1 | 1 | SEE BLANK | P.C. BOARD BLANK | ||||||||

| MAKE FROM S19399 (MAKES 18 BOARDS |

| |||||||||||

|

|

|

|

|

|

| |||||||

| PER PANEL, SEE ELECTRONIC FILE FOR |

| 2 | 10 | LED SPACER | ||||||||

|

| ||||||||||||

| ADDITIONAL INFORMATION) |

|

| FOR ITEMS BELOW REFER TO ELECTRONIC COMPONENTS DATABASE FOR COMPONENT SPECIFICATIONS | |||||||||

|

|

| |||||||||||

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

| ||||

| BLANK PART NUMBER |

|

|

|

|

|

| ||||||

|

|

|

|

| J61 | 1 | |||||||

|

|

|

|

|

|

|

|

|

| LED1,LED2,LED3,LED4,LED5 | 5 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| R1,R2 | 2 | POT,ST,0.5W,10K,10%,LINEAR | |

|

|

|

|

|

|

|

|

|

| S1 | 1 | SWITCH,PUSHBUTTON,SPST,GREEN,W/BLACK | |

RESISTANCE = OHMS

N.D.N.C.

LED/POT | MANUFACTURE AS: | |

| ||

|

R2 | R1 |

PART NO. |

| IDENTIFICATION CODE |

|

|

|

| ENCAPSULATE WITH E1844. (2 COATS) | |

5.35 | |||

BRUSH COAT ACCEPTABLE | |||

|

| ||

N.A.N.C.

NOTES:

N.A. DO NOT COAT WITH ENCAPSULATION MATERIAL.

N.B. THERE MUST NOT BE MORE THAN A .010 GAP

BETWEEN SPACER & LED, OR BETWEEN SPACER

&P.C. BOARD. ENCAPSULATE P.C. BOARD, SPACERS & LOWER HALF OF LED. LEDS MUST BE PERPENDICULAR WITH P.C. BOARD.

N.C. ENCAPSULATE AROUND BASE OF COMPONENT

N.D. COAT EXTERNAL PINS WITH ENCAPSULATION MATERIAL.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| SCHEMATIC REFERENCE: |

|

|

| FOR PARTS ORDERS ONLY: |

|

| ||||||||||

|

|

|

|

| |||||||||||||

|

|

|

| TEST PER |

|

| |||||||||||

|

|

|

|

|

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

| |||||||

THIS SHEET CONTAINS PROPRIETARY INFORMATION OWNED BY THE LINCOLN ELECTRIC COMPANY AND IS NOT TO BE REPRODUCED, DISCLOSED OR USED WITHOUT THE EXPRESS WRITTEN PERMISSION OF THE LINCOLN ELECTRIC COMPANY, CLEVELAND, OHIO U.S.A. |

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UNLESS OTHERWISE SPECIFIED TOLERANCE |

| "X" INFO. | Chg. Sheet No. |

| DESIGN INFORMATION | REFERENCE: | EQUIPMENT TYPE: | INVERTER WELDERS |

| ||||||||

MANUFACTURING TOLERANCE PER E2056 |

|

|

|

|

|

| EDGE | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

ON ALL ANGLES IS ± .5 OF A DEGREE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

ON 2 PLACE DECIMALS IS ± .02 |

|

|

| DRAWN BY: F.V. |

|

|

|

|

|

|

|

|

|

|

|

| |

ON 3 PLACE DECIMALS IS ± .002 |

|

|

|

|

| SUBJECT: | LED POT P.C. BOARD ASSEMBLY |

| |||||||||

MATERIAL TOLERANCE ("t") TO AGREE |

|

|

|

| ENGINEER: Craig Hejl | SUPERSEDING: | SOLID | ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

DO NOT SCALE THIS DRAWING |

|

|

|

| APPROVED: |

| SCALE:FULL | ||||||||||

WITH PUBLISHED STANDARDS. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTE: Lincoln Electric assumes no responsibility for liablilities resulting from board level troubleshooting. PC Board repairs will invalidate your factory warranty. Individual Printed Circuit Board Components are not available from Lincoln Electric. This information is pro- vided for reference only. Lincoln Electric discourages board level troubleshooting and repair since it may compromise the quality of the design and may result in danger to the Machine Operator or Technician. Improper PC board repairs could result in damage to the machine.