Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

| THEORY OF OPERATION | ||||||||

|

|

| |||||||

|

| FIGURE E.4 – POWER BOARD, CONTROL BOARD |

| ||||||

| AND SERIAL PERIPHERAL INTERFACE (SPI) COMMUNICATIONS | ||||||||

|

|

| Main Switch Board |

|

|

| To Control | ||

|

|

|

|

|

| Board |

| ||

|

|

|

|

|

|

|

| eedbackF | Current |

| Input |

|

|

|

|

|

|

| Positive |

Input switch |

|

| Primary |

|

|

|

| Output | |

Rectifier |

|

|

|

|

|

| Terminal | ||

|

| Current |

|

|

|

| |||

|

|

|

| Sensor |

|

|

|

|

|

|

| Reconnect |

|

|

|

|

| Choke | Negative |

|

|

|

|

|

|

|

| Output | |

|

| Switch |

|

|

|

|

|

| Terminal |

|

|

|

| Primary |

|

|

| Sense | |

|

|

|

| Current |

|

|

|

|

|

|

|

|

| Sensor |

|

|

|

|

|

|

| Fan | ControlanF |

|

|

| IGBTDriveSignal | VoltageOutput | |

24VAC |

| 115VAC Fan Supply | Primary Current Feedback | ||||||

|

|

| Input Relay Control |

|

|

|

| ||

|

|

|

|

|

|

|

| ||

Auxiliary |

|

| Soft Start Control |

|

|

|

| ||

115VAC, 42VAC Transformer |

|

| V/F Capacitor Feedback (2) |

|

|

|

| ||

|

|

|

|

|

|

|

| ||

|

| Machine Control Supply |

|

|

|

|

| ||

|

| +15VDC, |

|

|

|

|

| ||

|

| Power |

|

|

|

|

|

|

|

28VAC |

| Board SPI Supply +15VDC +5VDC |

|

| Control Board |

| |||

40VDC |

|

|

|

|

|

|

| ||

14 Pin |

| RS232 Supply +5VDC |

|

|

|

|

| ||

|

|

|

|

|

|

|

| RS232 | |

Amphenol |

|

|

|

|

|

|

|

| |

|

|

|

| SPI Communications | & +15VDC, +5VDC Supply | ||||

|

| Remote Control & Trigger Remote |

| Mode | Advanced | ||||

|

|

| Panel | Display | Process | ||||

|

|

|

| Board |

| Panel | |||

|

|

|

|

| (Not used if APP | Panel | |||

|

|

|

|

|

| is in place) |

| ||

6 Pin |

|

|

| 12 |

|

|

|

|

|

|

|

| VDC |

|

|

|

|

| |

Amphenol |

|

|

|

|

|

|

|

| |

|

|

| Output | Weld | Optional Solenoid |

|

| ||

|

|

| Control | Terminals |

|

| |||

|

| Output |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| |

|

| Potentiometer |

|

|

|

|

|

| |

Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

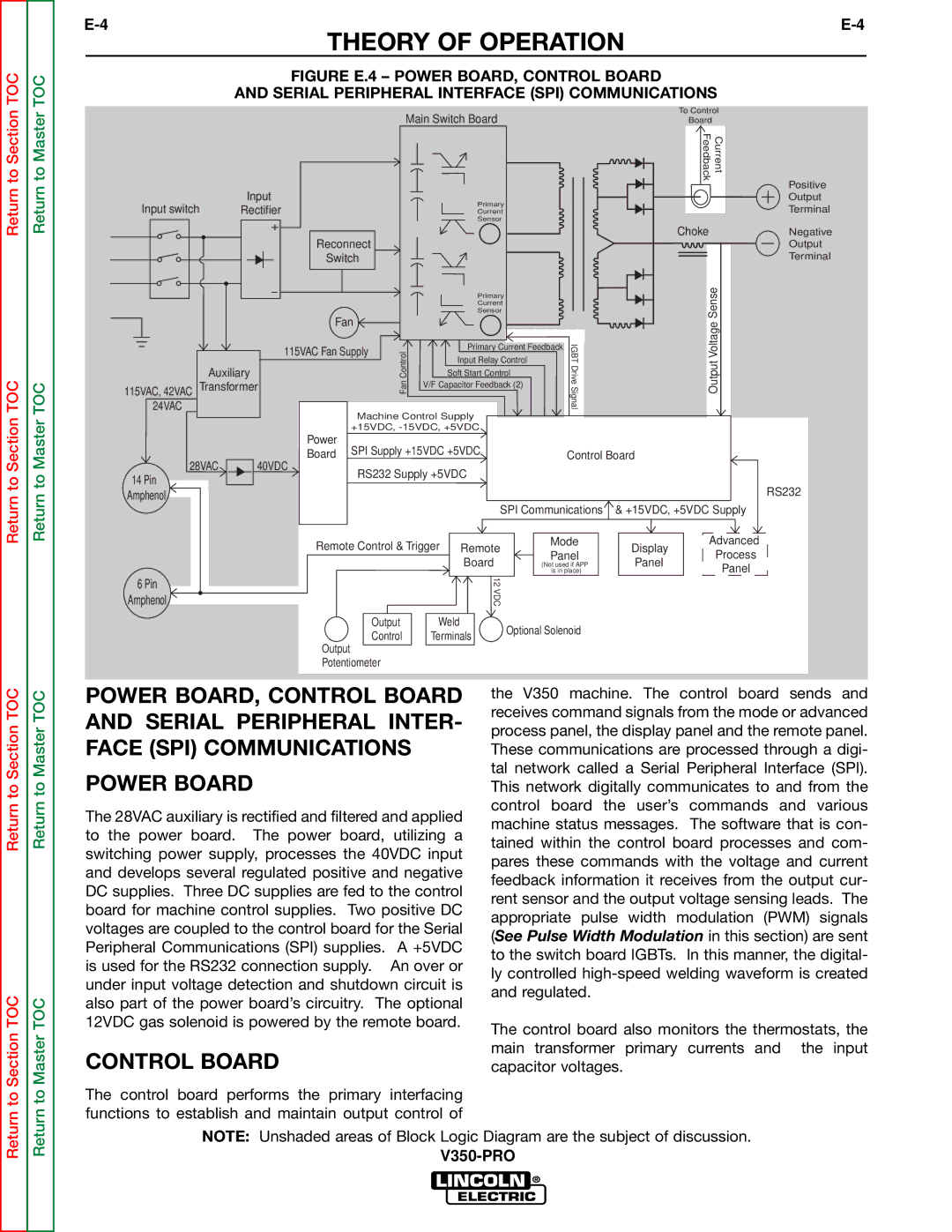

POWER BOARD, CONTROL BOARD AND SERIAL PERIPHERAL INTER- FACE (SPI) COMMUNICATIONS

POWER BOARD

The 28VAC auxiliary is rectified and filtered and applied to the power board. The power board, utilizing a switching power supply, processes the 40VDC input and develops several regulated positive and negative DC supplies. Three DC supplies are fed to the control board for machine control supplies. Two positive DC voltages are coupled to the control board for the Serial Peripheral Communications (SPI) supplies. A +5VDC is used for the RS232 connection supply. An over or under input voltage detection and shutdown circuit is also part of the power board’s circuitry. The optional 12VDC gas solenoid is powered by the remote board.

CONTROL BOARD

The control board performs the primary interfacing functions to establish and maintain output control of

the V350 machine. The control board sends and receives command signals from the mode or advanced process panel, the display panel and the remote panel. These communications are processed through a digi- tal network called a Serial Peripheral Interface (SPI). This network digitally communicates to and from the control board the user’s commands and various machine status messages. The software that is con- tained within the control board processes and com- pares these commands with the voltage and current feedback information it receives from the output cur- rent sensor and the output voltage sensing leads. The appropriate pulse width modulation (PWM) signals (See Pulse Width Modulation in this section) are sent to the switch board IGBTs. In this manner, the digital- ly controlled

The control board also monitors the thermostats, the main transformer primary currents and the input capacitor voltages.

Return

Return

NOTE: Unshaded areas of Block Logic Diagram are the subject of discussion.