OPERATION

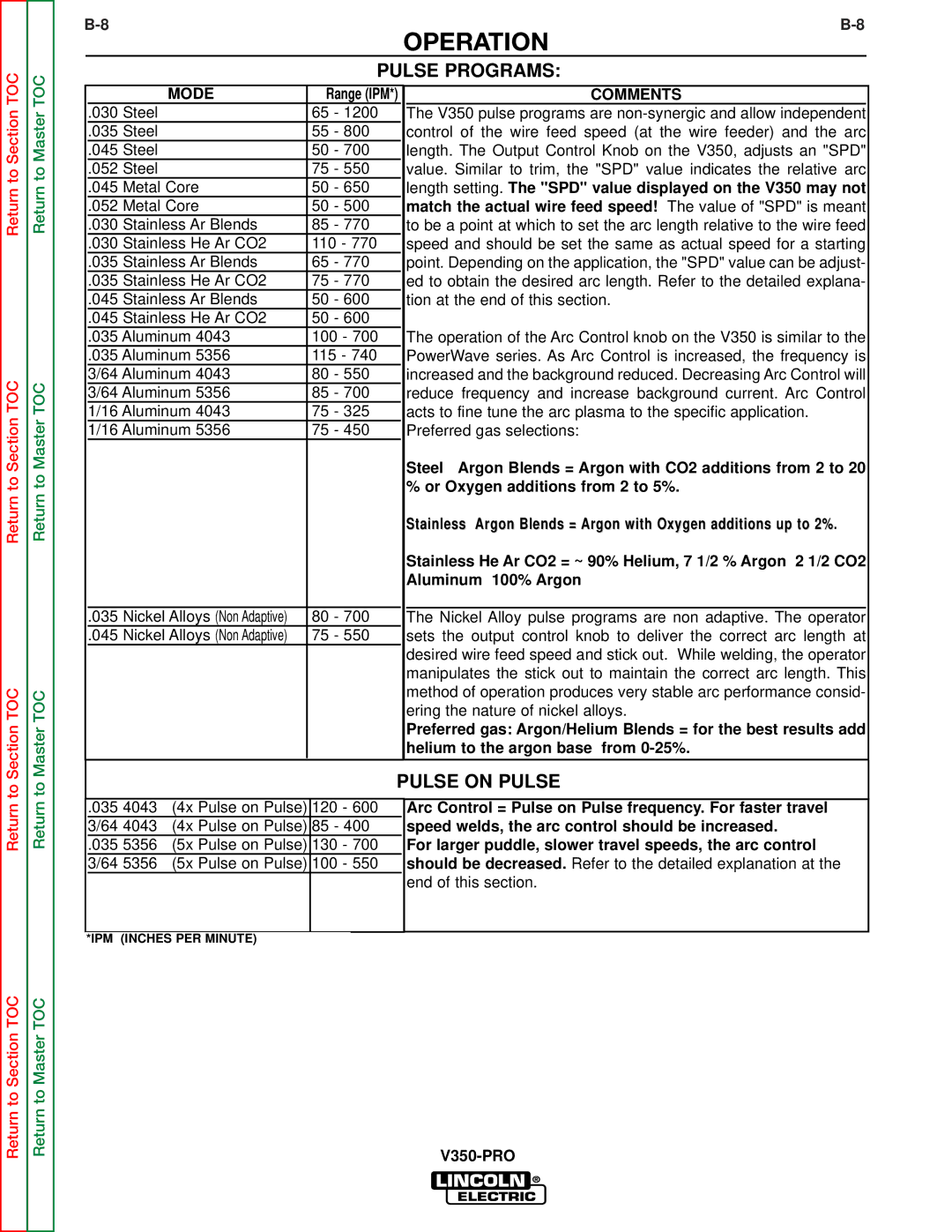

PULSE PROGRAMS:

Return to Section TOC

Return to Section TOC

Section TOC

Return to Master TOC

Return to Master TOC

Master TOC

| MODE | Range (IPM*) | |

.030 | Steel | 65 | - 1200 |

.035 | Steel | 55 | - 800 |

.045 | Steel | 50 | - 700 |

.052 | Steel | 75 | - 550 |

.045 | Metal Core | 50 | - 650 |

.052 | Metal Core | 50 | - 500 |

.030 | Stainless Ar Blends | 85 | - 770 |

.030 | Stainless He Ar CO2 | 110 - 770 | |

.035 | Stainless Ar Blends | 65 | - 770 |

.035 | Stainless He Ar CO2 | 75 | - 770 |

.045 | Stainless Ar Blends | 50 | - 600 |

.045 | Stainless He Ar CO2 | 50 | - 600 |

.035 Aluminum 4043 | 100 - 700 | ||

.035 Aluminum 5356 | 115 - 740 | ||

3/64 Aluminum 4043 | 80 | - 550 | |

3/64 Aluminum 5356 | 85 | - 700 | |

1/16 Aluminum 4043 | 75 | - 325 | |

1/16 Aluminum 5356 | 75 | - 450 | |

.035 Nickel Alloys (Non Adaptive) | 80 - 700 |

.045 Nickel Alloys (Non Adaptive) | 75 - 550 |

COMMENTS

The V350 pulse programs are

The operation of the Arc Control knob on the V350 is similar to the PowerWave series. As Arc Control is increased, the frequency is increased and the background reduced. Decreasing Arc Control will reduce frequency and increase background current. Arc Control acts to fine tune the arc plasma to the specific application.

Preferred gas selections:

Steel Argon Blends = Argon with CO2 additions from 2 to 20 % or Oxygen additions from 2 to 5%.

Stainless Argon Blends = Argon with Oxygen additions up to 2%.

Stainless He Ar CO2 = ~ 90% Helium, 7 1/2 % Argon 2 1/2 CO2 Aluminum 100% Argon

The Nickel Alloy pulse programs are non adaptive. The operator sets the output control knob to deliver the correct arc length at desired wire feed speed and stick out. While welding, the operator manipulates the stick out to maintain the correct arc length. This method of operation produces very stable arc performance consid- ering the nature of nickel alloys.

Preferred gas: Argon/Helium Blends = for the best results add helium to the argon base from

Return to

Return to Section TOC

Return to

Return to Master TOC

|

|

|

|

|

| PULSE ON PULSE | ||

|

|

|

|

|

|

|

| |

.035 4043 | (4x | Pulse on Pulse) | 120 - 600 |

|

| Arc Control = Pulse on Pulse frequency. For faster travel | ||

| 3/64 4043 | (4x | Pulse on Pulse) | 85 - 400 |

|

| speed welds, the arc control should be increased. | |

| .035 5356 | (5x | Pulse on Pulse) | 130 - 700 |

|

| For larger puddle, slower travel speeds, the arc control | |

| 3/64 5356 | (5x | Pulse on Pulse) | 100 - 550 |

|

| should be decreased. Refer to the detailed explanation at the | |

|

|

|

|

|

|

|

| end of this section. |

|

|

|

|

|

| |||

*IPM (INCHES PER MINUTE) |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|