User Documentation

Operating Instructions Issue 07/04

Parameter List

Micromaster 420 Documentation

Getting Started Guide

Operating Instructions

Valid for Release

Operating Instructions

Micromaster

Central Technical Support

Online Service & Support

User Documentation

Information is also available from Regional Contacts

Qualified personnel

Use for intended purpose only

General

Safety Instructions

Commissioning

Transport & Storage

Dismantling & Disposal

Operation

Repair

Safety Instructions Issue 07/04

Table of Contents

154

151

152

153

List of Illustrations

OFF1

List of Tables

Table of Contents Issue 07/04

This Chapter contains

Overview

Micromaster

Performance Characteristics

Features

Main Characteristics

Options

Protection characteristics

Installation

Installation Issue 07/04

Ambient operating conditions

Installation after a Period of Storage

Temperature

General

Shock and Vibration

Installation and cooling

Humidity

Altitude

Mechanical installation

Removing the Inverter from the rail

Mounting on standard rail, Frame Size a

Fitting the Inverter to a 35 mm standard rail EN

Inverter must always be grounded

Electrical installation

Operation with long cables

General

Operation with ungrounded IT supplies

Operation with Residual Current Device

Access to the power and motor terminals

Power and motor connections

Three Phase

Single Phase

Terminal Designation Function

Control terminals

Action to Take

Avoiding Electro-Magnetic Interference EMI

Screening without a Gland Plate

Screening Methods

Gland Plate

Installation Issue 07/04

This Section includes the following

Functions

Functions Issue 07/04

Issue 07/04 Functions

Notation

Setting / monitoring parameters and parameter attributes

Setting parameters

Parameters

Monitoring parameters

Attribute Description Group

Inverter

Rated motor current

P03053

P0003 =

P0003 =

P0004 =

Significance / command source

Interconnecting signals Bico technology

Main setpoint source Supplementary setpoint source

Significance

Command source

Selection of command/frequency setpoint P0719

Bico technology

BI Binector Input, signal receiver P parameters

BO Binector Output, signal source r parameters

Abbreviation and symbol Name Function

CO Connector Output, signal source r parameters

CI Connector Input, signal sink P parameters

P0731 =

P1070 =

P0840 =

P2051 =

Parameter Designation Value 100 % Units

Reference quantities

Interface 100 %

Example

Description of the BOP Basic Operator Panel

Operator panels for Micromaster

Description of the AOP Advanced Operator Panel

Operator Function Effects Panel/key

Keys and their functions on the operator panel BOP / AOP

Step Result on the display

Changing parameters using the operator panel

Changing P0004 parameter filter function

External 24

Block diagram

Parameter Function

Factory setting

13 Recommended wiring for the factory setting

Commissioning

14 Procedure when commissioning

Check list

15 DIP switch to change-over between 50/60 Hz

1 50/60 Hz setting

Commissioning parameter

Factory setting User access level

Quick commissioning

Parameterizing the drive with BOP or AOP

Rated motor voltage

Europe kW, frequency default 50 Hz

Rated motor power

Europe/ North America

Selection of frequency setpoint

Selection of command source

Control mode

End of quick commissioning/ drive setting

17 Example of a typical motor rating plate

Nema Motor

IEC Motor

19 Star / delta circuit configurations

Hz characteristic

87 Hz

Calculating the motor / control data

Motor data identification stator resistance

Motor data identification routine

Ambient motor temperature entered in C

Power-up the motor

Disabled

Serial Interface USS

Commissioning the application

Adapting the drive inverter to the application

Digital input DIN

5.2 Selection of command source

Selection of frequency setpoint

Digital output Dout

5.5

5.7 Analog output DAC

Analog input ADC

Fixed frequency FF

Motor potentiometer MOP

Ramp-function generator HLG

5.10 JOG

Motor control

Reference/limit frequencies

Slip compensation entered in %

Acceleration boost entered in %

Starting boost entered in %

Programmable V/f freq .0 Hz coord

Inverter/motor protection

Holding brake

Inverter-specific Functions Flying start

Automatic restart

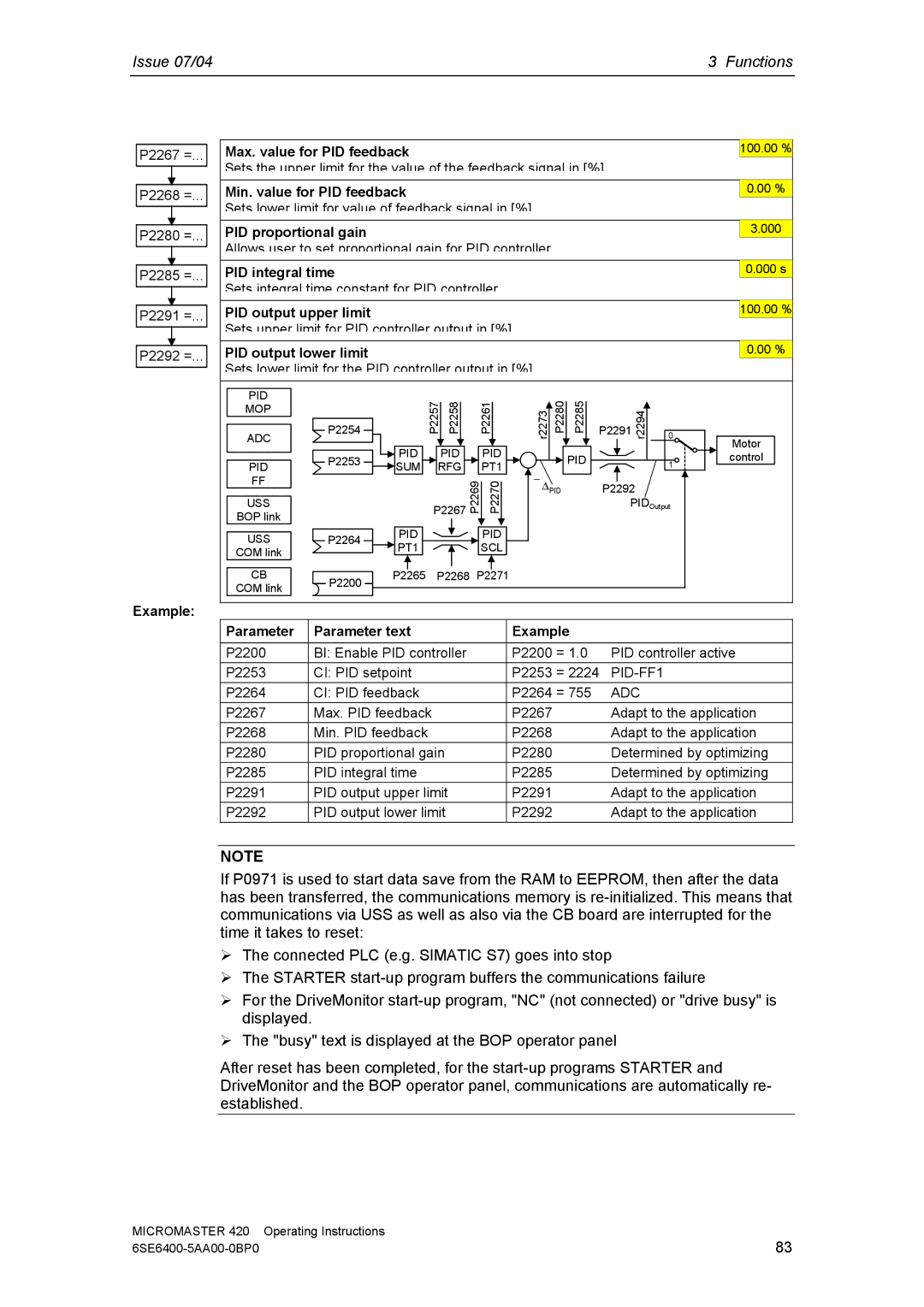

PID controller

DC braking

Compound braking

Vdc controller

Parameter Parameter text Example

Max. value for PID feedback

Sets lower limit for the PID controller output in %

Example

MM4

Series commissioning

Issue 07/04 Functions

Factory reset

Parameter reset to the factory setting

Reset to the factory setting

Digital inputs DIN

Inputs / outputs

Parameter value Significance

P0701 P0703 digital inputs 1-3 or P0707 P0703 analog input

Example

Bico parameterization

Digital output Dout

11 Parameter P0731 frequently used functions / states

ADC channel

Analog input ADC

26 Wire breakage monitoring

Wire breakage monitoring

Analog output DAC

27 Signal output through the DAC channel

Starter USS

Communications

COM link interface CB on COM link USS on COM link

BOP link interface BOP on BOP link USS on BOP link

USS at the COM link RS485

30 RS485 Terminator

USS bus configuration via COM link RS485

Direct selection

Fixed frequencies FF

Direct selection + on command

R0722.1

Binary-coded selection + on command

Selecting via serial interfaces

Motorized potentiometer MOP

AOP at the BOP link

Selecting via BOP or AOP

Parameters / keys

35 JOG counter-clockwise and JOG clockwise

10 JOG

105

36 Structure of the technological controller PID controller

PID controller technological controller

Parameterizations

PID motorized potentiometer Motorized potentiometer

PID motorized potentiometer PID-MOP

PID fixed setpoint PID-FF

Summation and modification of the frequency setpoint AFM

Setpoint channel

111

With rounding

Ramp-function generator RFG

P1134 =

P1132 P1133

Parameter Description

19 Bico parameters for ramp-function generator

OFF1

12.3 OFF/braking functions

OFF2

Manual / automatic operation

Parameter setting Command source

Value Command source Setpoint source

On / OFF1/OFF3

Motor holding brake MHB

49 Motor holding brake after OFF2

On / OFF2

121

14.1 DC braking

Electronic brakes

51 DC braking after OFF1 / OFF3

Sequence ➀

52 DC braking after external selection

Sequence ➁

53 Compound braking

Compound braking

126

Blackout Brownout

Automatic restart

Line undervoltage brownout

Line failure blackout

128

Flying restart active Search direction

Flying restart

130

Cause

Closed-loop Vdc control

Vdcmax controller

DC link undervoltage

132

General monitoring functions / messages

Monitoring functions / messages

Functions / states

Function chart

Thermal motor model

Features

Thermal motor protection and overload responses

136

Temperature Classes

19.2 PTC temperature sensor

58 Connecting a temperature sensor to Micromaster

General overload monitoring

Power module protection

Fault and shutdown

I2t monitoring

Heatsink temperature

Thermal monitoring functions and overload responses

Reducing the output frequency P0290 = 0,2

Reducing the pulse frequency P0290 = 2

Disadvantage

No reduction P0290 =

21.1 Control

Open-loop/closed-loop control technique

Use / property

27 V/f characteristic parameter P1300

Parameter Voltage boost Explanation

Voltage boost

146

21.1.2 V/f open-loop control with flux current control FCC

62 Slip compensation

Slip compensation

63 Effect of V/f resonance damping

21.1.4 V/f resonance damping

Imax controller setpoint

Current limiting Imax controller

Troubleshooting

Troubleshooting Issue 07/04

Troubleshooting with the SDP

Troubleshooting with the BOP

Alarm messages

Fault messages and alarm messages

Fault messages

Suppressing fault / alarm messages

156

Micromaster 420 specifications

Feature Specification

Micromaster 420 specifications Issue 07/04

KHz 10 kHz 12 kHz 14 kHz 16 kHz

Lbs

2AB11 2AB12 2AB13 2AB15 2AB17 2AB21 2AB22 2AB23

1BA1 5BA1

Awg

Input voltage range AC 200 V 240 V, ± 10 % Unfiltered

2UC11 2UC12 2UC13 2UC15 2UC17 2UC21 2UC22 2UC23

KVA

2UC25

2UC12 2UC13

1BA1 5BA1 2BA1

2BA1 0BA1

2AD23 2AD24

2AD31

2UD25 2UD27 2UD31

Input voltage range AC 380 V 480 V, ± 10 % Unfiltered

2UD13 2UD15 2UD17 2UD21 2UD22 2UD23 2UD24

Device-dependent options

Options

Device-independent options

Options Issue 07/04

Electro-magnetic compatibility EMC

EC type examination certificate

Electro-magnetic compatibility EMC

Self-certification

Technical construction file

EMC Directive Compliance with Imminent Harmonics Regulations

EMC Phenomenon Standard Level

Classification of EMC performance

Class 1 General Industrial

Class 2 Filtered Industrial

171

Class

Model Remarks

Class 1 General Industrial

Appendices Changing the OperatorPanel

Removing Covers Frame Size a

Removing Covers

6SE6400-5AA00-0BP0

Removing ‘Y’ Cap Frame Size a

Removing ‘Y’ Cap

Issue 07/04 Removing ‘Y’ Cap

Removing fan, Frame Size a

Removing fan

Removing fan, Frame Sizes B and C

Applicable Standards

COM

List of Abbreviations

List of Abbreviations Issue 07/04

PPO

Index

Issue 07/04 Index

Ungrounded IT supplies

Suggestions Corrections

Suggestions and/or Corrections

188

Frame Size B & C

View of Unit Frame Size a

Siemens Aktiengesellschaft

![]()

![]() SUM

SUM![]() PID

PID![]() − ∆ PID

− ∆ PID