DISASSEMBLY AND ASSEMBLY

3.2.6.6 PG Sensor and PG Motor Removal

![]()

![]() CAUTION

CAUTION

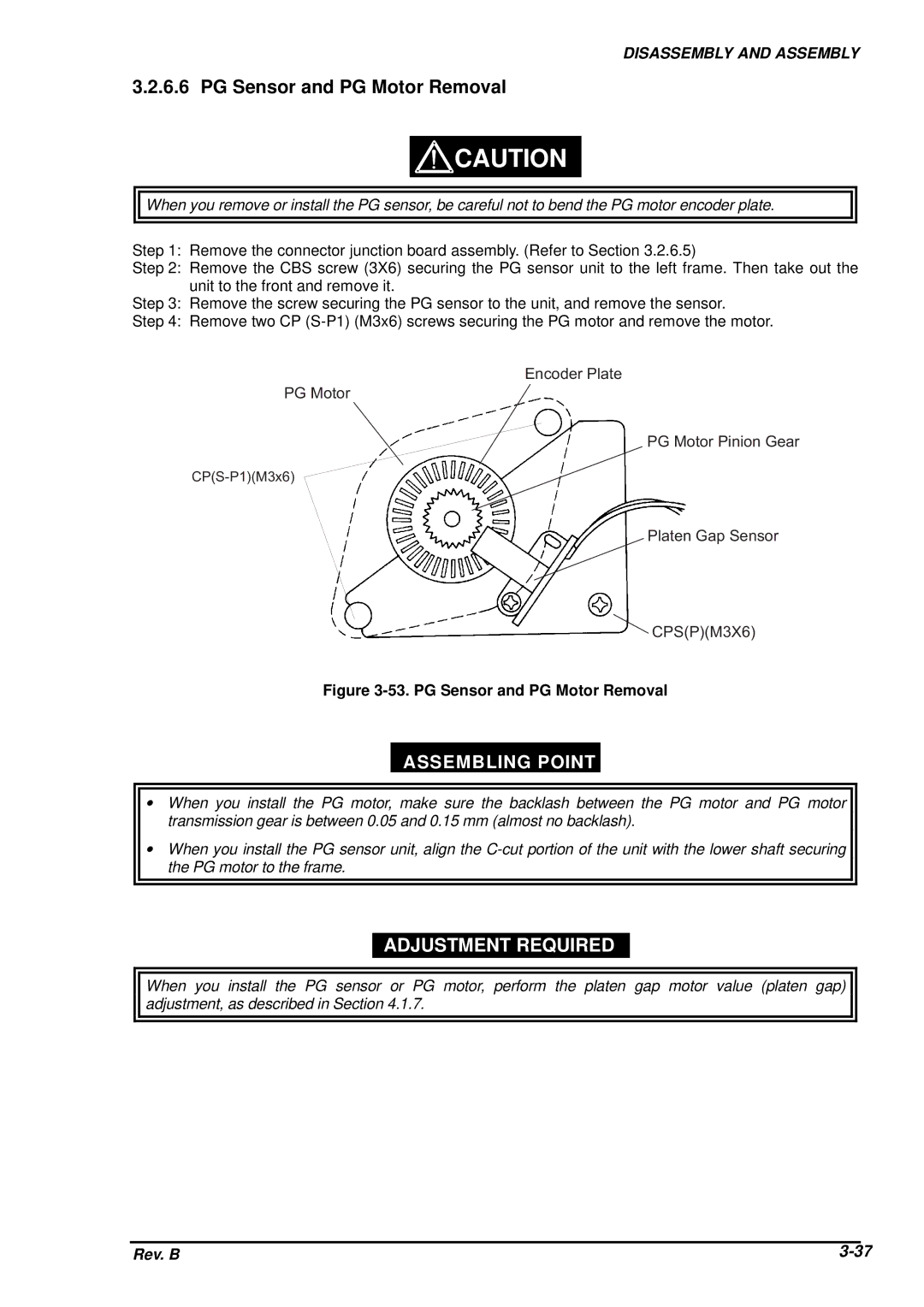

When you remove or install the PG sensor, be careful not to bend the PG motor encoder plate.

Step 1: Remove the connector junction board assembly. (Refer to Section 3.2.6.5)

Step 2: Remove the CBS screw (3X6) securing the PG sensor unit to the left frame. Then take out the unit to the front and remove it.

Step 3: Remove the screw securing the PG sensor to the unit, and remove the sensor.

Step 4: Remove two CP

E n c o d e r P la t e

P G M o t o r

P G M o t o r P in

C P ( S - P 1 ) ( M 3 x 6 )

P la t e n G a p S

C P S ( P ) ( M 3 X 6 )

Figure 3-53. PG Sensor and PG Motor Removal

ASSEMBLING POINT

∙When you install the PG motor, make sure the backlash between the PG motor and PG motor transmission gear is between 0.05 and 0.15 mm (almost no backlash).

∙When you install the PG sensor unit, align the

ADJUSTMENT REQUIRED

When you install the PG sensor or PG motor, perform the platen gap motor value (platen gap) adjustment, as described in Section 4.1.7.

Rev. B |