DFX-8500

2.1.3 Platen Gap Adjustment Mechanism

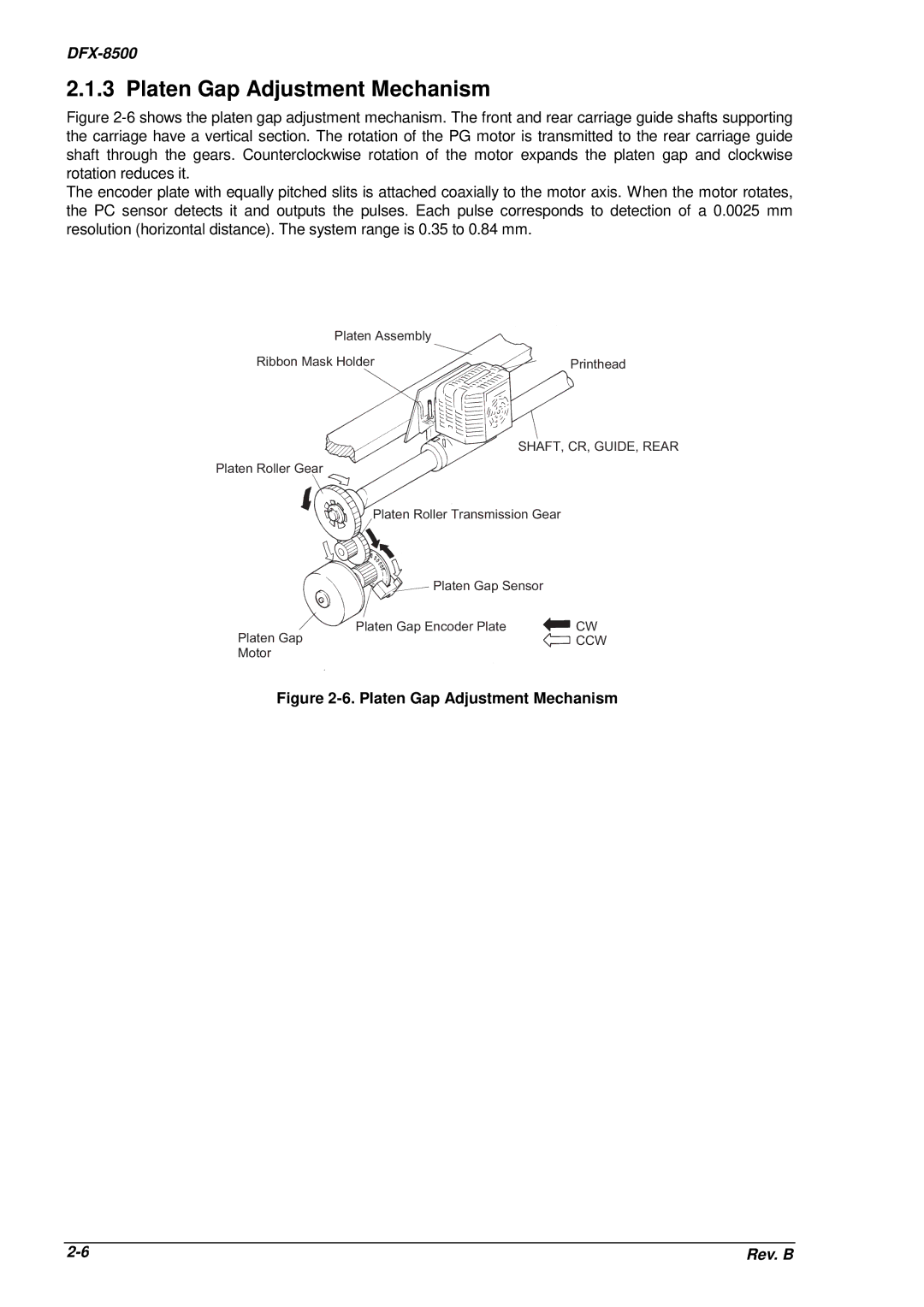

Figure 2-6 shows the platen gap adjustment mechanism. The front and rear carriage guide shafts supporting the carriage have a vertical section. The rotation of the PG motor is transmitted to the rear carriage guide shaft through the gears. Counterclockwise rotation of the motor expands the platen gap and clockwise rotation reduces it.

The encoder plate with equally pitched slits is attached coaxially to the motor axis. When the motor rotates, the PC sensor detects it and outputs the pulses. Each pulse corresponds to detection of a 0.0025 mm resolution (horizontal distance). The system range is 0.35 to 0.84 mm.

P la t e n A s s e m b ly

R ib b o n M a s k ![]() H o ld Pe r in t h e a d

H o ld Pe r in t h e a d

| S H A F T , C R , G U I D E , R E A |

P la t e n R o lle r G e a r | |

P la t e n | R o lle r T r a n s m is s io n G e |

P la t e n G a p S e n s o r | |

P la t e n | G a p ECnWc o d e r P la t e |

P la t e n G a p | C C W |

M o t o r

Figure 2-6. Platen Gap Adjustment Mechanism

Rev. B |