DFX-8500

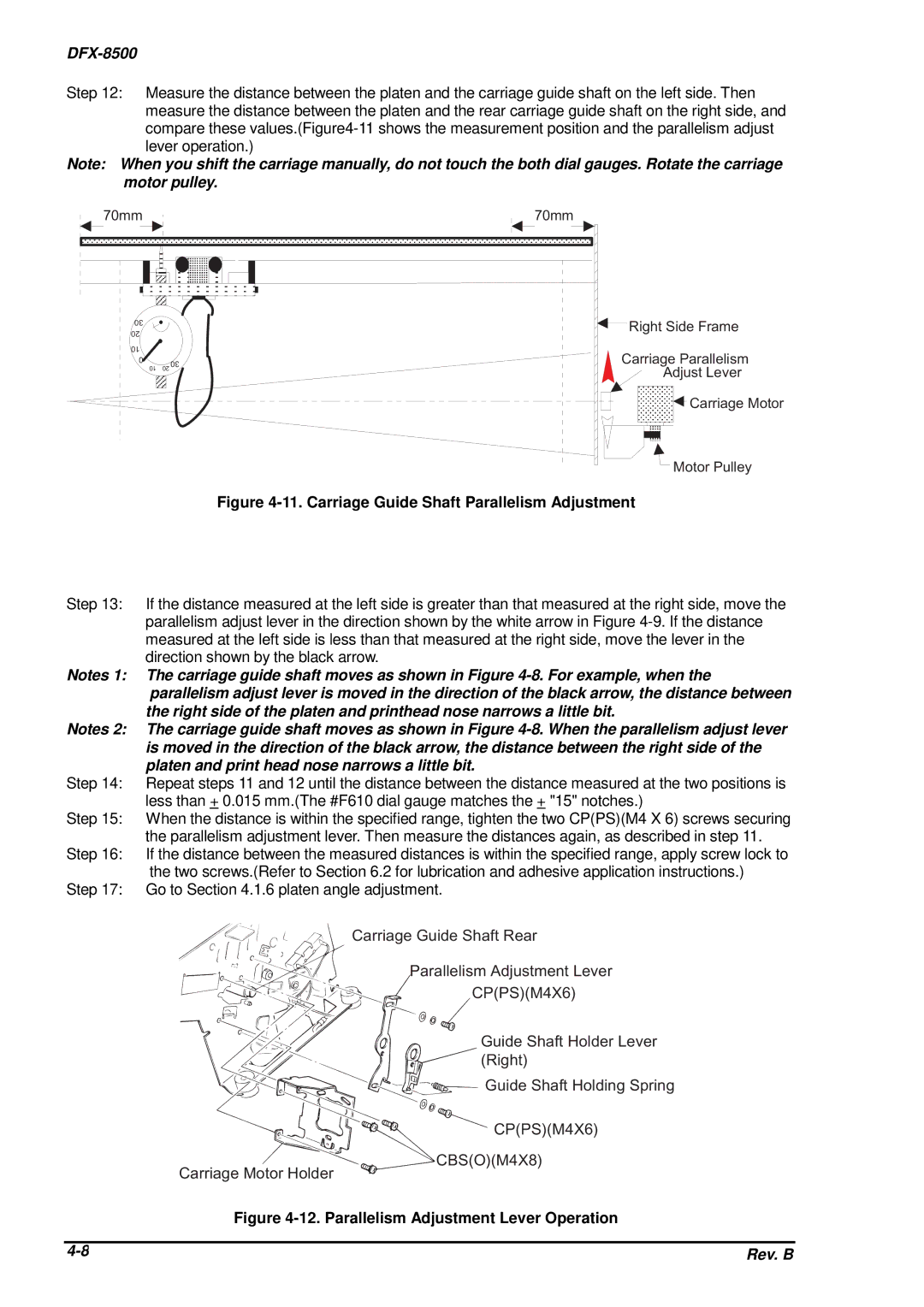

Step 12: Measure the distance between the platen and the carriage guide shaft on the left side. Then measure the distance between the platen and the rear carriage guide shaft on the right side, and compare these

Note: When you shift the carriage manually, do not touch the both dial gauges. Rotate the carriage motor pulley.

7 0 m m | 7 0 m m |

0 3

02

01

00 3

0 10 2

![]() R ig h t S id e F r a m

R ig h t S id e F r a m

C a r r ia g e P a r a ll

A d ju s t L e v e r

![]() C a r r ia g e M o

C a r r ia g e M o

M o t o r P u lle y

Figure 4-11. Carriage Guide Shaft Parallelism Adjustment

Step 13: If the distance measured at the left side is greater than that measured at the right side, move the parallelism adjust lever in the direction shown by the white arrow in Figure

Notes 1: The carriage guide shaft moves as shown in Figure

Notes 2: The carriage guide shaft moves as shown in Figure

Step 14: Repeat steps 11 and 12 until the distance between the distance measured at the two positions is less than + 0.015 mm.(The #F610 dial gauge matches the + "15" notches.)

Step 15: When the distance is within the specified range, tighten the two CP(PS)(M4 X 6) screws securing the parallelism adjustment lever. Then measure the distances again, as described in step 11.

Step 16: If the distance between the measured distances is within the specified range, apply screw lock to the two screws.(Refer to Section 6.2 for lubrication and adhesive application instructions.)

Step 17: Go to Section 4.1.6 platen angle adjustment.

Carriage Guide Shaft Rear

Parallelism Adjustment Lever

CP(PS)(M4X6)

Guide Shaft Holder Lever (Right)

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Guide Shaft Holding Spring

Guide Shaft Holding Spring

CP(PS)(M4X6)

CBS(O)(M4X8)

Carriage Motor Holder

Figure 4-12. Parallelism Adjustment Lever Operation

Rev. B |