OPERATING PRINCIPLES

2.1.4 Paper Feed Mechanism

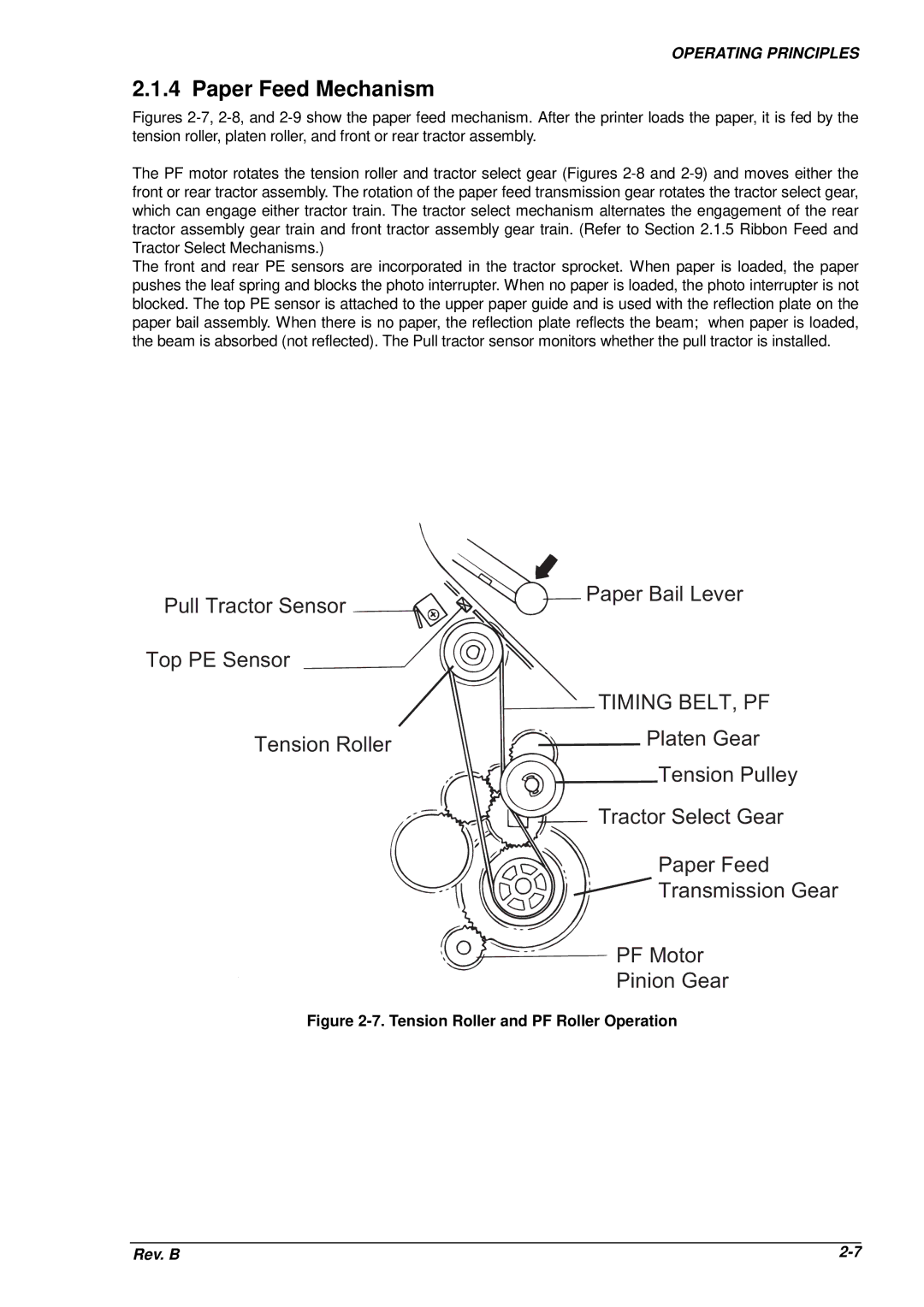

Figures 2-7, 2-8, and 2-9 show the paper feed mechanism. After the printer loads the paper, it is fed by the tension roller, platen roller, and front or rear tractor assembly.

The PF motor rotates the tension roller and tractor select gear (Figures 2-8 and 2-9) and moves either the front or rear tractor assembly. The rotation of the paper feed transmission gear rotates the tractor select gear, which can engage either tractor train. The tractor select mechanism alternates the engagement of the rear tractor assembly gear train and front tractor assembly gear train. (Refer to Section 2.1.5 Ribbon Feed and Tractor Select Mechanisms.)

The front and rear PE sensors are incorporated in the tractor sprocket. When paper is loaded, the paper pushes the leaf spring and blocks the photo interrupter. When no paper is loaded, the photo interrupter is not blocked. The top PE sensor is attached to the upper paper guide and is used with the reflection plate on the paper bail assembly. When there is no paper, the reflection plate reflects the beam; when paper is loaded, the beam is absorbed (not reflected). The Pull tractor sensor monitors whether the pull tractor is installed.

Pull Tractor Sensor | Paper Bail Lever |

| |

Top PE Sensor |

|

| TIMING BELT, PF |

Tension Roller | Platen Gear |

| |

| Tension Pulley |

| Tractor Select Gear |

| Paper Feed |

| Transmission Gear |

PF Motor

Pinion Gear

Figure 2-7. Tension Roller and PF Roller Operation

Rev. B |