ADJUSTMENT

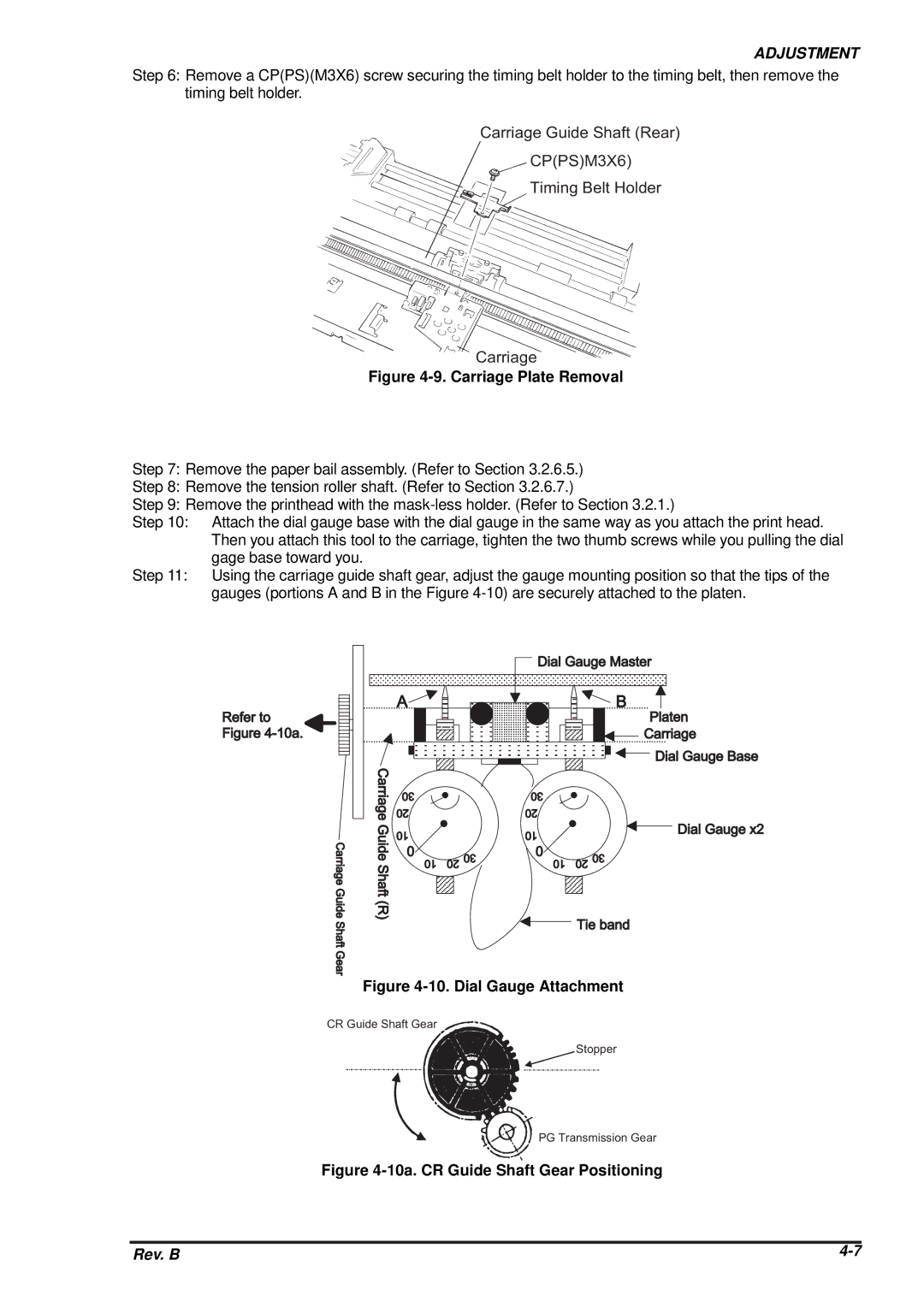

Step 6: Remove a CP(PS)(M3X6) screw securing the timing belt holder to the timing belt, then remove the timing belt holder.

C a r r ia g e |

C P ( P S ) |

T im in g |

G u id e | S h a f |

M 3 X 6 ) |

|

B e lt | H o ld e |

C a r r ia g e

Figure 4-9. Carriage Plate Removal

Step 7: Remove the paper bail assembly. (Refer to Section 3.2.6.5.)

Step 8: Remove the tension roller shaft. (Refer to Section 3.2.6.7.)

Step 9: Remove the printhead with the

Step 10: Attach the dial gauge base with the dial gauge in the same way as you attach the print head. Then you attach this tool to the carriage, tighten the two thumb screws while you pulling the dial gage base toward you.

Step 11: Using the carriage guide shaft gear, adjust the gauge mounting position so that the tips of the gauges (portions A and B in the Figure

Referto

CariageGuideShaftGear

| DialGaugeMaster |

A | B |

| Platen |

| Cariage |

CariageGuideShaft(R) |

|

|

| DialGaugeBase |

30 |

| 30 |

| |

|

|

| ||

| 20 |

| 20 | DialGaugex2 |

| 10 |

| 10 | |

|

|

| ||

| 0 | 30 | 0 | 30 |

|

|

| ||

|

| 10 20 |

| 10 20 |

![]() Tieband

Tieband

Figure 4-10. Dial Gauge Attachment

C R G u id e S h a f t G e a r

S t o p p e r

P G T r a n s m is s io n G e a r

Figure 4-10a. CR Guide Shaft Gear Positioning

Rev. B |