1. Introduction

1.3 PROFIBUS DP

Overview of PROFIBUS DP

PROFIBUS DP is one of fieldbus networks that provide easy interconnection between control devices (PLC, PC, sensor, actuator, etc.).

PROFIBUS DP was

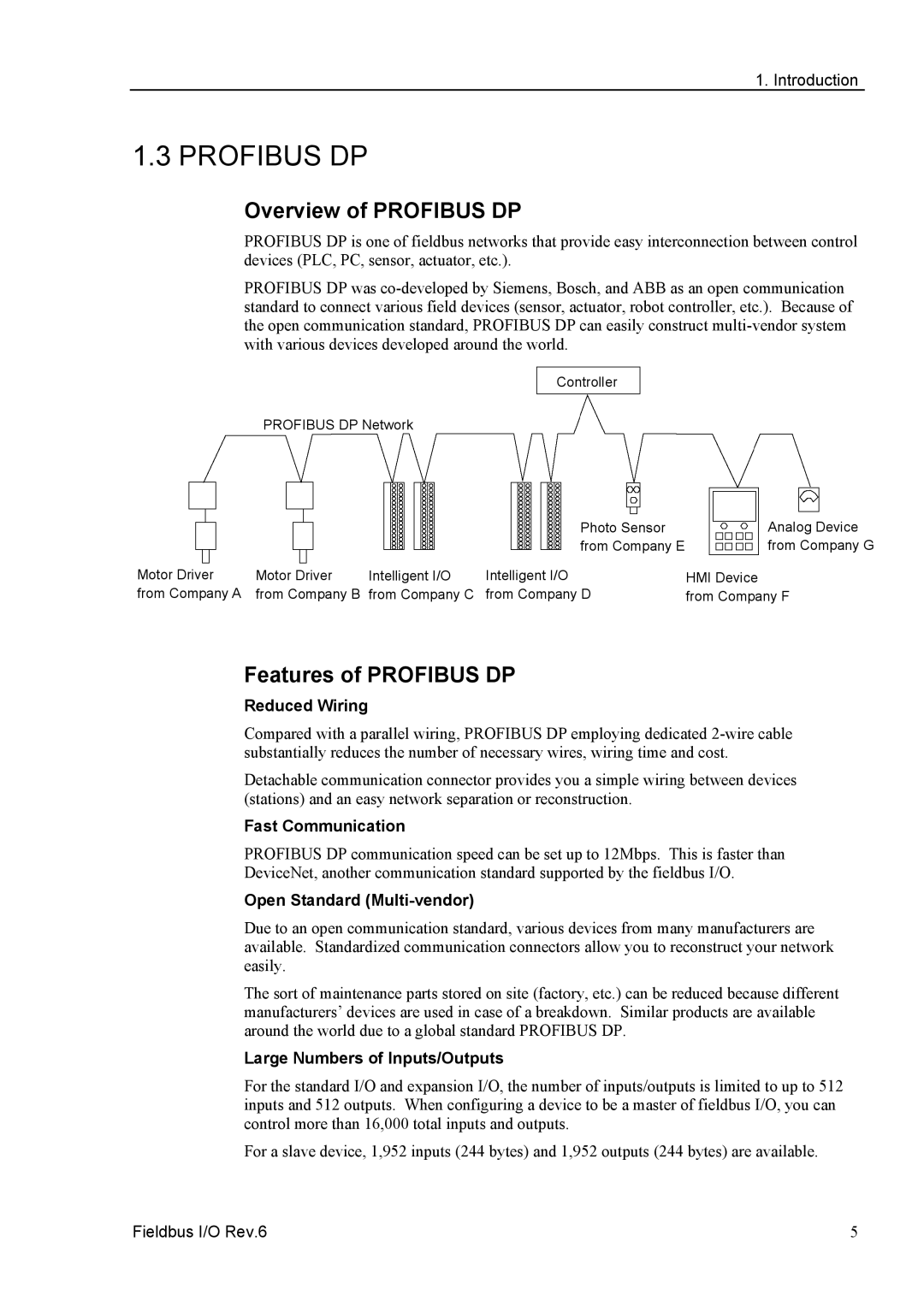

Controller

PROFIBUS DP Network

|

|

| Photo Sensor | Analog Device |

|

|

| from Company E | from Company G |

Motor Driver | Motor Driver | Intelligent I/O | Intelligent I/O | HMI Device |

from Company A | from Company B from Company C | from Company D | from Company F | |

Features of PROFIBUS DP

Reduced Wiring

Compared with a parallel wiring, PROFIBUS DP employing dedicated

Detachable communication connector provides you a simple wiring between devices (stations) and an easy network separation or reconstruction.

Fast Communication

PROFIBUS DP communication speed can be set up to 12Mbps. This is faster than

DeviceNet, another communication standard supported by the fieldbus I/O.

Open Standard (Multi-vendor)

Due to an open communication standard, various devices from many manufacturers are available. Standardized communication connectors allow you to reconstruct your network easily.

The sort of maintenance parts stored on site (factory, etc.) can be reduced because different manufacturers’ devices are used in case of a breakdown. Similar products are available around the world due to a global standard PROFIBUS DP.

Large Numbers of Inputs/Outputs

For the standard I/O and expansion I/O, the number of inputs/outputs is limited to up to 512 inputs and 512 outputs. When configuring a device to be a master of fieldbus I/O, you can control more than 16,000 total inputs and outputs.

For a slave device, 1,952 inputs (244 bytes) and 1,952 outputs (244 bytes) are available.

Fieldbus I/O Rev.6 | 5 |