| INSTALLATION | ||

TRAILERS (See ACCESSORIES SECTION) | POLARITY CONTROL AND CABLE SIZES | ||

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

If the user adapts a

1.Design capacity of trailer vs. weight of Lincoln equipment and likely additional attachments.

2.Proper support of, and attachment to, the base of the welding equipment so there will be no undue stress to the framework.

3.Proper placement of the equipment on the trailer to ensure stability side to side and front to back when being moved and when standing by itself while being operated or serviced.

4.Typical conditions of use, i.e., travel speed; rough- ness of surface on which the trailer will be operat- ed; environmental conditions; likely maintenance.

5.Conformance with federal, state, and local laws. (1)

(1)Consult applicable federal, state, and local laws regarding specific requirements for use on pub- lic highways.

VEHICLE MOUNTINGWARNING

Improperly mounted concentrated loads may cause unstable vehicle handling and tires or other components to fail.

•Only transport this Equipment on serviceable vehicles which are rated and designed for such loads.

•Distribute, balance and secure loads so vehicle is stable under conditions of use.

•Do not exceed maximum rated loads for compo- nents such as suspension, axles and tires.

•Mount equipment base to metal bed or frame of vehicle.

•Follow vehicle manufactureʼs instructions.

With the engine off, route the electrode and work cables through the strain relief bracket on the base and connect to the studs located below the fuel tank mount- ing rail. (see size recommendations below). For Positive polarity, connect the electrode cable to the terminal marked “Positive”. For Negative polarity, connect the electrode cable to the “Negative” stud. These connections should be checked periodically and tightened if necessary.

When welding at a considerable distance from the welder, be sure you use ample size welding cables.

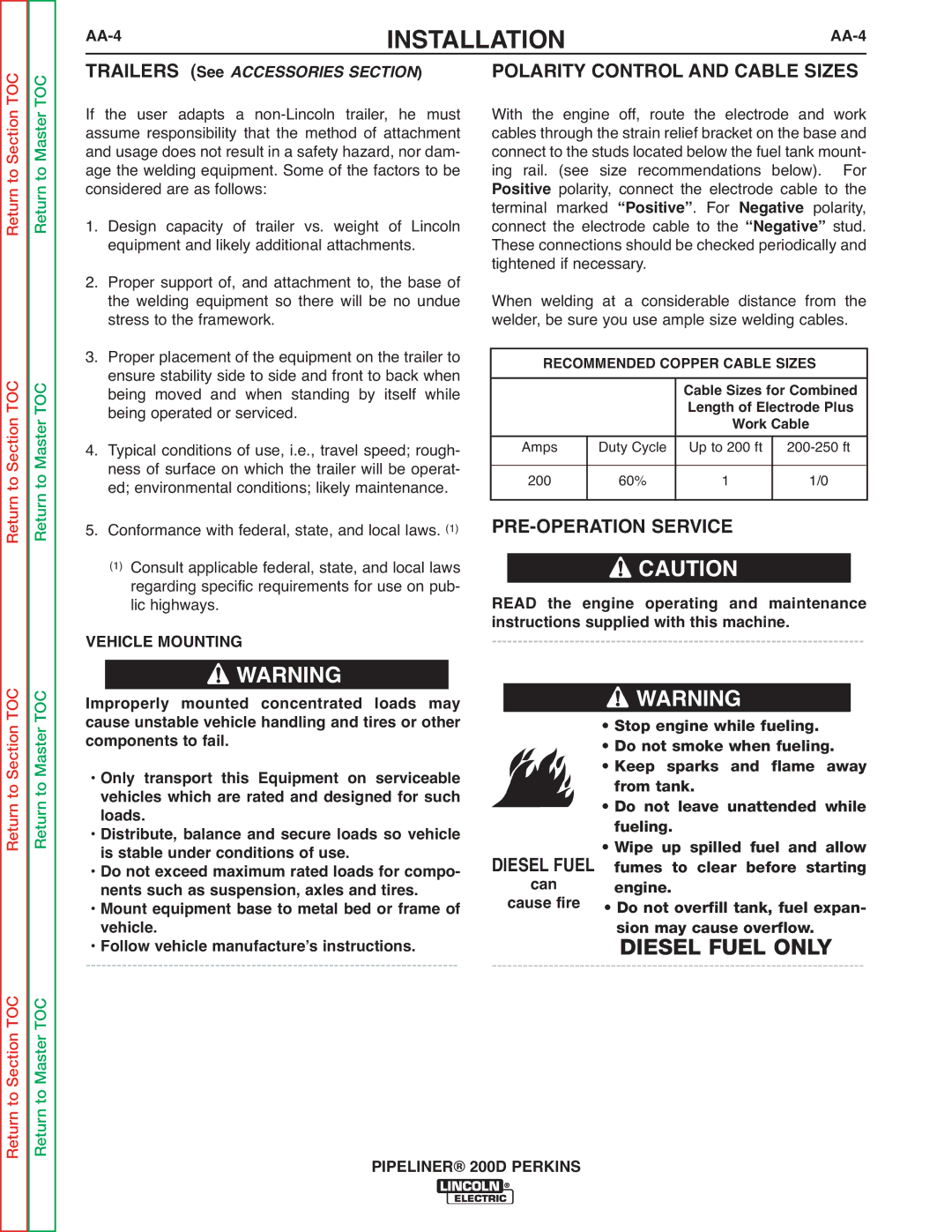

RECOMMENDED COPPER CABLE SIZES | ||||

|

| Cable Sizes for Combined | ||

|

| Length of Electrode Plus | ||

|

| Work Cable | ||

Amps | Duty Cycle | Up to 200 ft | ||

200 | 60% | 1 | 1/0 |

|

| |

| |

| CAUTION |

READ the engine operating and maintenance | |

instructions supplied with this machine. | |

| WARNING |

| • Stop engine while fueling. |

| • Do not smoke when fueling. |

| • Keep sparks and flame away |

| from tank. |

| • Do not leave unattended while |

DIESEL FUEL | fueling. |

• Wipe up spilled fuel and allow | |

fumes to clear before starting | |

can | engine. |

cause fire | • Do not overfill tank, fuel expan- |

sion may cause overflow.

Return to Section TOC

Return to Master TOC