Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

TROUBLESHOOTING & REPAIR | ||

TOC | IDLER SOLENOID TEST (continued) |

|

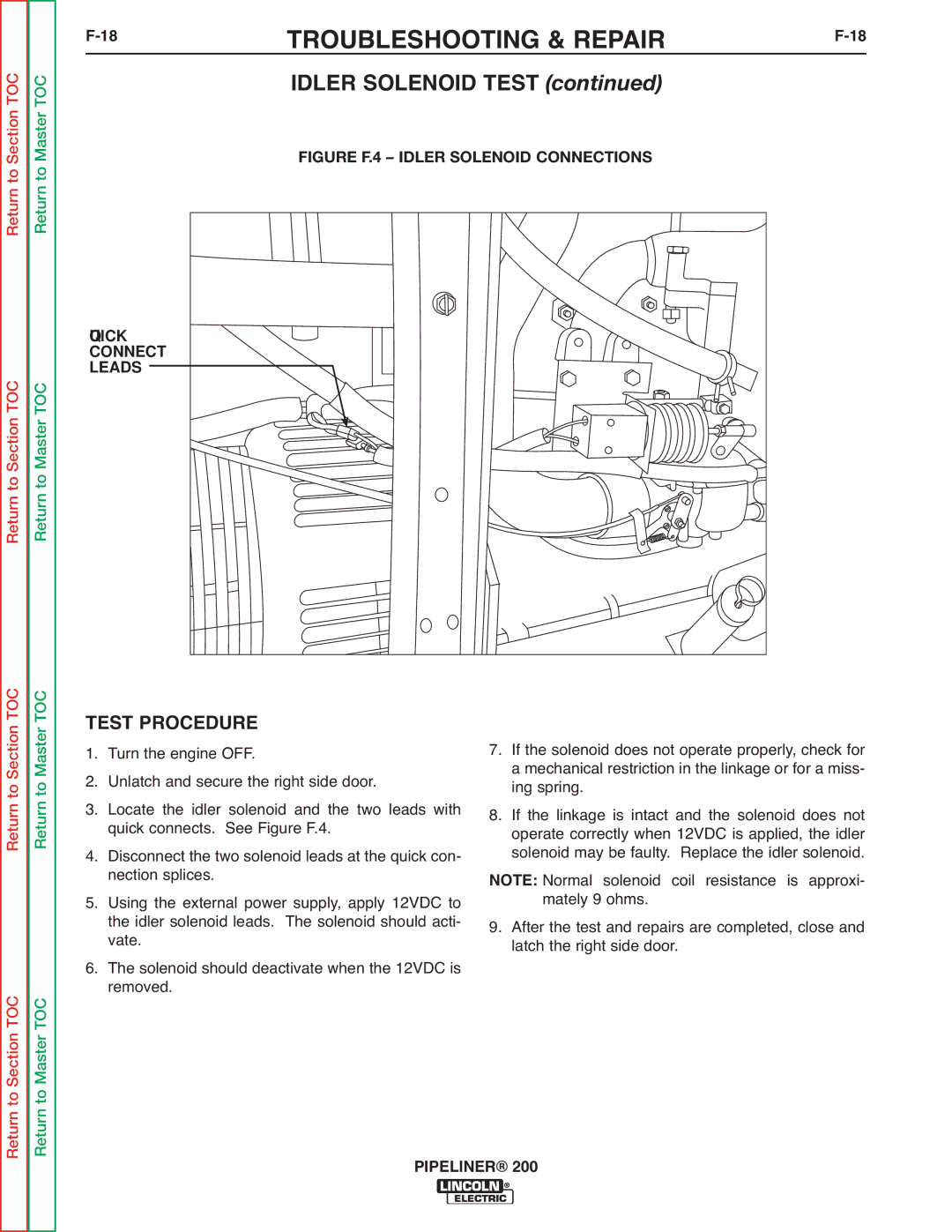

Master | FIGURE F.4 – IDLER SOLENOID CONNECTIONS |

|

Return to |

| |

|

| |

QUICK |

|

|

CONNECT |

|

|

LEADS |

|

|

Return to Master TOC |

|

|

TOC | TEST PROCEDURE | 7. | If the solenoid does not operate properly, check for | |

Masterto | 1. | Turn the engine OFF. | ||

2. | Unlatch and secure the right side door. |

| ing spring. | |

| 3. | Locate the idler solenoid and the two leads with |

| a mechanical restriction in the linkage or for a miss- |

Return | 8. | If the linkage is intact and the solenoid does not | ||

4. | quick connects. See Figure F.4. |

| operate correctly when 12VDC is applied, the idler | |

| Disconnect the two solenoid leads at the quick con- |

| solenoid may be faulty. Replace the idler solenoid. | |

| 5. | nection splices. | NOTE: Normal solenoid coil resistance is approxi- | |

| Using the external power supply, apply 12VDC to | 9. | mately 9 ohms. | |

|

| the idler solenoid leads. The solenoid should acti- | After the test and repairs are completed, close and | |

| 6. | vate. |

| latch the right side door. |

| The solenoid should deactivate when the 12VDC is |

| ||

Return to Master TOC |

| removed. |

|

|

| PIPELINER® 200 | |||

|

| |||