Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

| INSTALLATION |

|

|

|

|

|

|

|

| |||||||

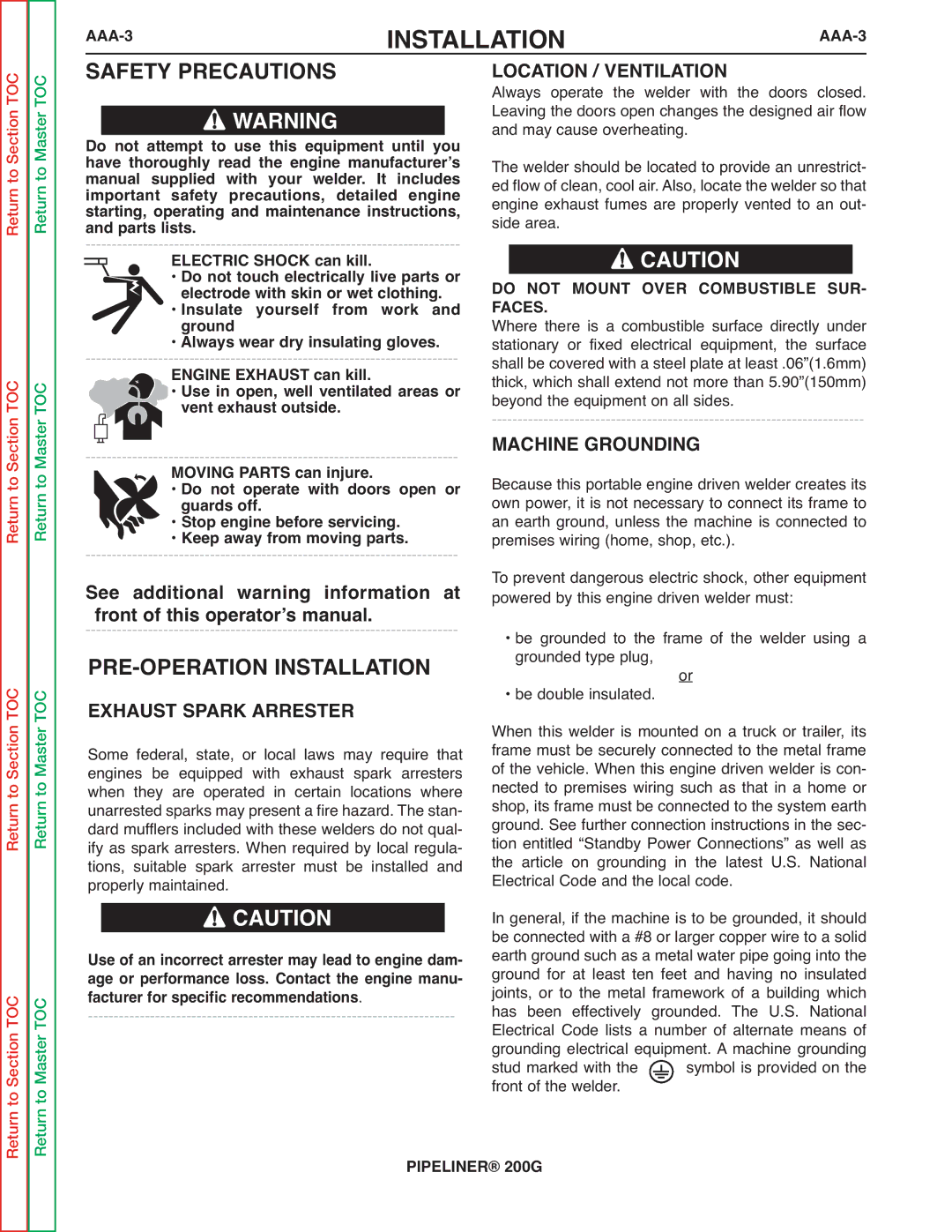

SAFETY PRECAUTIONS |

|

| LOCATION / VENTILATION |

| |||||||||||||

|

| Always operate the welder with the doors closed. | |||||||||||||||

|

|

|

|

|

| WARNING |

|

| Leaving the doors open changes the designed air flow | ||||||||

|

|

|

|

|

|

|

| and may cause overheating. |

| ||||||||

Do not attempt to use this equipment until y | ou |

|

|

|

|

|

|

|

|

| |||||||

have thoroughly read the engine manufacturerʼs | The welder should be located to provide an unrestrict- | ||||||||||||||||

manual supplied with your welder. It includes | |||||||||||||||||

important safety precautions, detailed engine | ed flow of clean, cool air. Also, locate the welder so that | ||||||||||||||||

starting, operating and maintenance instructions, | engine exhaust fumes are properly vented to an out- | ||||||||||||||||

and parts lists. |

|

|

| side area. |

|

|

|

|

|

|

|

| |||||

| CAUTION |

| |||||||||||||||

|

|

|

|

| ELECTRIC SHOCK can kill. |

|

|

|

| ||||||||

|

|

|

|

| • Do not touch electrically live parts or |

|

| ||||||||||

|

|

|

|

| electrode with skin or wet clothing. | DO NOT MOUNT OVER COMBUSTIBLE SUR- | |||||||||||

|

|

|

|

| • Insulate yourself from | work and | FACES. |

|

|

|

|

|

|

|

| ||

|

|

|

|

| ground |

|

| Where there is a combustible surface directly under | |||||||||

|

|

|

|

| • Always wear dry insulating gloves. | stationary or fixed electrical equipment, the surface | |||||||||||

shall be covered with a steel plate at least .06”(1.6mm) | |||||||||||||||||

|

|

|

|

| ENGINE EXHAUST can kill. |

|

| thick, which shall extend not more than 5.90”(150mm) | |||||||||

|

|

|

|

| • Use in open, well ventilated areas or | beyond the equipment on all sides. |

| ||||||||||

|

|

|

|

| vent exhaust outside. |

|

| ||||||||||

|

|

|

|

| MACHINE GROUNDING |

| |||||||||||

|

|

|

|

|

| ||||||||||||

|

|

|

|

| MOVING PARTS can injure. |

|

| Because this portable engine driven welder creates its | |||||||||

|

|

|

|

| • Do not operate with doors open or | ||||||||||||

|

|

|

|

| guards off. |

|

| own power, it is not necessary to connect its frame to | |||||||||

|

|

|

|

| • Stop engine before servicing. | an earth ground, unless the machine is connected to | |||||||||||

|

|

|

|

| • Keep away from moving parts. | premises wiring (home, shop, etc.). |

| ||||||||||

To prevent dangerous electric shock, other equipment | |||||||||||||||||

See additional warning information at | powered by this engine driven welder must: |

| |||||||||||||||

| front of this operatorʼs manual. |

|

| • be grounded to the frame of the welder using a | |||||||||||||

| grounded type plug, |

|

| or |

| ||||||||||||

EXHAUST SPARK ARRESTER |

|

| • be double insulated. |

|

|

|

| ||||||||||

|

| When this welder is mounted on a truck or trailer, its | |||||||||||||||

Some federal, state, or local laws may require that | frame must be securely connected to the metal frame | ||||||||||||||||

engines be equipped with exhaust spark arresters | of the vehicle. When this engine driven welder is con- | ||||||||||||||||

when they are operated in certain locations where | nected to premises wiring such as that in a home or | ||||||||||||||||

unarrested sparks may present a fire hazard. The stan- | shop, its frame must be connected to the system earth | ||||||||||||||||

dard mufflers included with these welders do not qual- | ground. See further connection instructions in the sec- | ||||||||||||||||

ify as spark arresters. When required by local regula- | tion entitled “Standby Power Connections” as well as | ||||||||||||||||

tions, suitable spark arrester must be installed and | the article on grounding in the latest U.S. National | ||||||||||||||||

properly maintained. | CAUTION |

|

| Electrical Code and the local code. |

| ||||||||||||

|

|

|

|

|

|

|

| In general, if the machine is to be grounded, it should | |||||||||

|

|

|

|

|

|

|

| be connected with a #8 or larger copper wire to a solid | |||||||||

Use of an incorrect arrester may lead to engine dam- | earth ground such as a metal water pipe going into the | ||||||||||||||||

age or performance loss. Contact the engine manu- | ground for at least ten feet and having no insulated | ||||||||||||||||

facturer for specific recommendations. |

|

| joints, or to the metal framework of a building which | ||||||||||||||

has been effectively grounded. The U.S. National | |||||||||||||||||

Electrical Code lists a number of alternate means of | |||||||||||||||||

|

|

|

|

|

|

|

|

| grounding electrical equipment. A machine grounding | ||||||||

|

|

|

|

|

|

|

|

| stud marked with the |

|

|

|

|

|

| symbol is provided on the | |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

| front of the welder. |

|

|

|

|

|

|

|

|

PIPELINER® 200G