Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

F-14 TROUBLESHOOTING & REPAIRF-14

DC EXCITER TEST (CONTINUED)

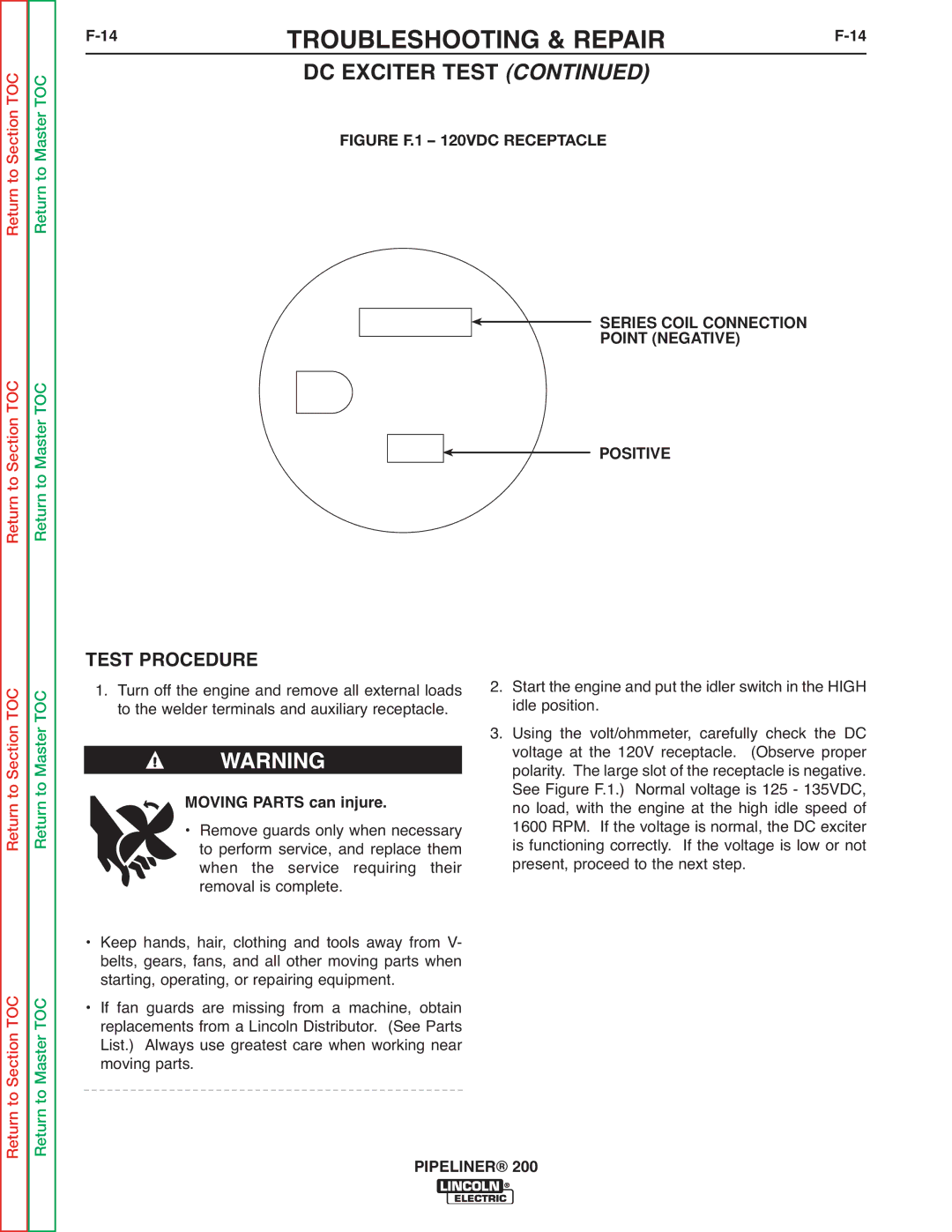

FIGURE F.1 – 120VDC RECEPTACLE

SERIES COIL CONNECTION

SERIES COIL CONNECTION

POINT (NEGATIVE)

POSITIVE

TEST PROCEDURE | 2. Start the engine and put the idler switch in the HIGH | ||||

| 1. Turn off the engine and remove all external loads | ||||

| to the welder terminals and auxiliary receptacle. | idle position. | |||

| 3. Using the volt/ohmmeter, carefully check the DC | ||||

|

|

| WARNING | polarity. The large slot of the receptacle is negative. | |

|

|

|

|

| voltage at the 120V receptacle. (Observe proper |

|

|

| MOVING PARTS can injure. | See Figure F.1.) Normal voltage is 125 - 135VDC, | |

|

|

| |||

|

|

| no load, with the engine at the high idle speed of | ||

|

|

| • Remove guards only when necessary | 1600 RPM. If the voltage is normal, the DC exciter | |

|

|

| to perform service, and replace them | is functioning correctly. If the voltage is low or not | |

|

|

| when the service requiring their | present, proceed to the next step. | |

|

|

| removal is complete. |

| |

• Keep hands, hair, clothing and tools away from V- |

| ||||

| belts, gears, fans, and all other moving parts when |

| |||

| starting, operating, or repairing equipment. |

| |||

• If fan guards are missing from a machine, obtain |

| ||||

| replacements from a Lincoln Distributor. (See Parts |

| |||

| List.) Always use greatest care when working near |

| |||

| moving parts. |

|

| ||