Return to Section TOC

Return to Master TOC

F-62 TROUBLESHOOTING & REPAIRF-62

MAIN GENERATOR ARMATURE

REMOVAL AND REPLACEMENT PROCEDURE

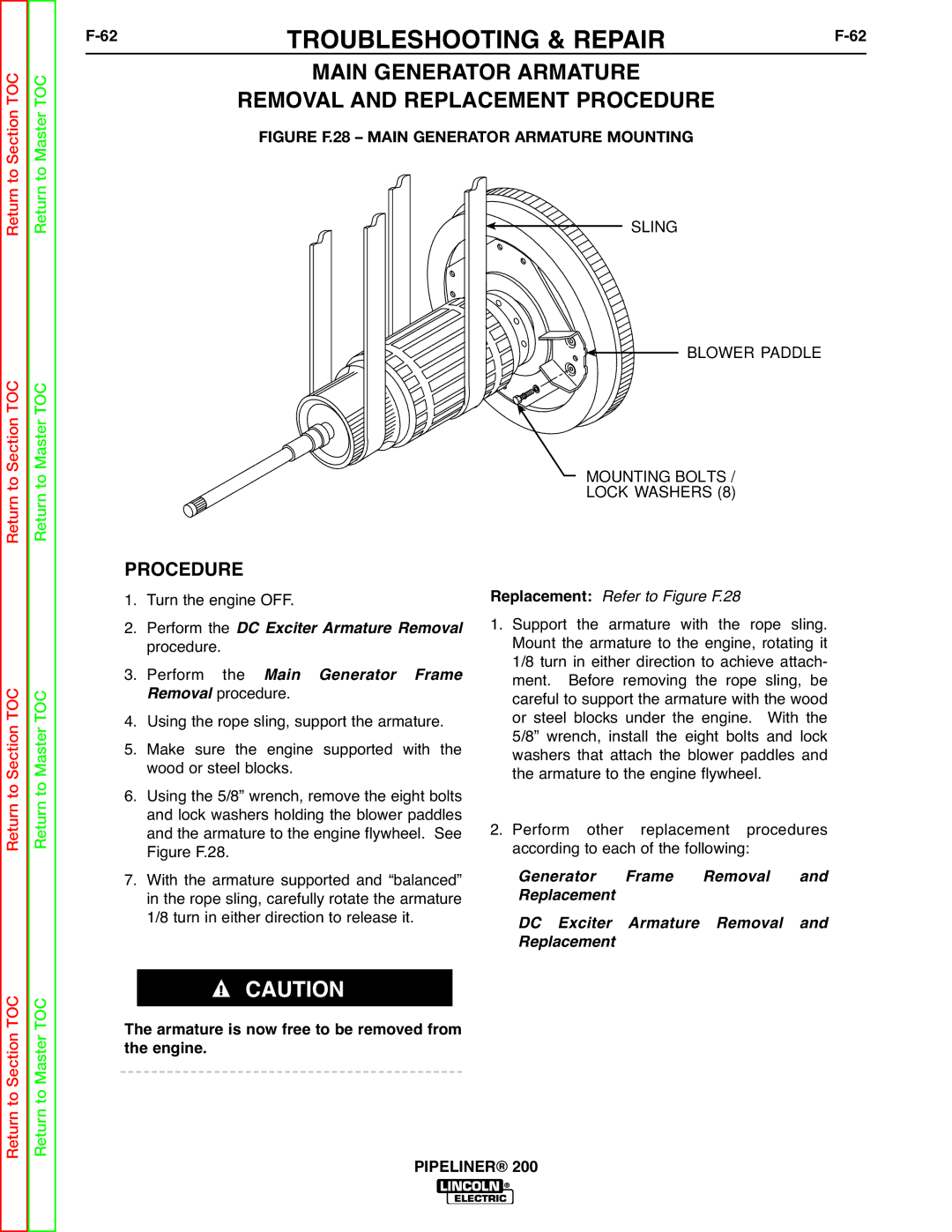

FIGURE F.28 – MAIN GENERATOR ARMATURE MOUNTING

Return to Section TOC

Return to Section TOC

to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1. Turn the engine OFF.

2. Perform the DC Exciter Armature Removal

procedure.

3. Perform the Main Generator Frame

Removal procedure.

4. Using the rope sling, support the armature.

5. Make sure the engine supported with the wood or steel blocks.

6. Using the 5/8” wrench, remove the eight bolts and lock washers holding the blower paddles and the armature to the engine flywheel. See Figure F.28.

7. With the armature supported and “balanced” in the rope sling, carefully rotate the armature 1/8 turn in either direction to release it.

CAUTION

The armature is now free to be removed from the engine.

SLING

BLOWER PADDLE

BLOWER PADDLE

MOUNTING BOLTS /

LOCK WASHERS (8)

Replacement: Refer to Figure F.28

1. Support the armature with the rope sling. Mount the armature to the engine, rotating it 1/8 turn in either direction to achieve attach- ment. Before removing the rope sling, be careful to support the armature with the wood or steel blocks under the engine. With the 5/8” wrench, install the eight bolts and lock washers that attach the blower paddles and the armature to the engine flywheel.

2. Perform other replacement procedures according to each of the following:

Generator Frame Removal and Replacement

DC Exciter Armature Removal and Replacement

Return