to Section TOC

to Master TOC

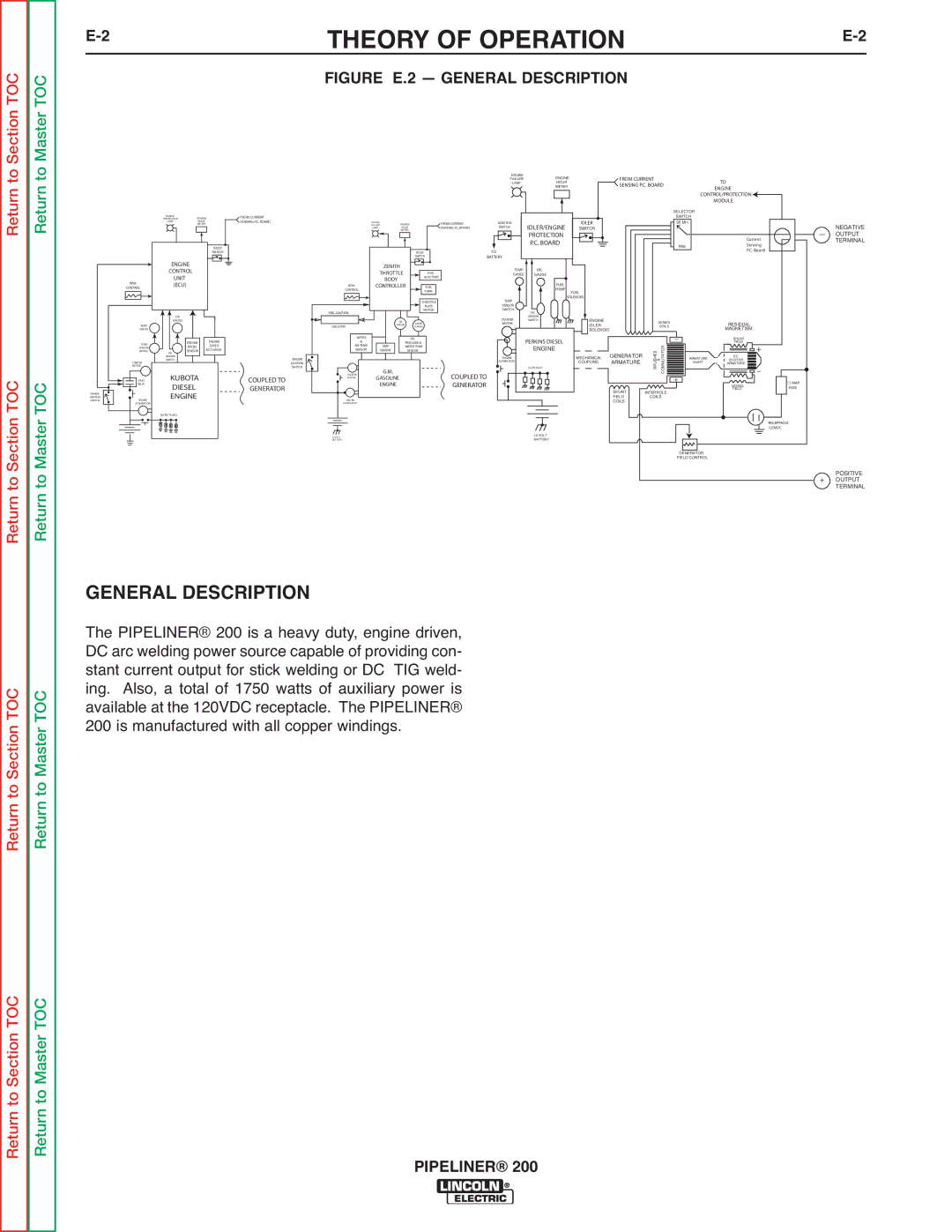

THEORY OF OPERATION | ||

| FIGURE E.2 — GENERAL DESCRIPTION |

|

ENGINE | ENGINE | FROM CURRENT |

|

FAILURE | TO | ||

LAMP | HOUR | SENSING P.C. BOARD | |

| METER | ENGINE | |

|

|

| CONTROL/PROTECTION |

|

|

| MODULE |

ENGINE |

| ENGINE | FROM CURRENT | |

PROTECTION |

| |||

LAMP |

| HOUR | SENSING P.C. BOARD | |

|

| METER |

| |

|

|

|

|

|

| SELECTOR |

|

|

|

|

|

|

| SWITCH |

|

ENGINE | ENGINE | FROM CURRENT | IGNITION |

| IDLER | 90 Min. | NEGATIVE |

FAILURE | IDLER/ENGINE | ||||||

LAMP | HOUR | SENSING P.C. BOARD | SWITCH | SWITCH |

| ||

| METER |

|

|

| |||

|

|

|

| PROTECTION |

| - | OUTPUT |

|

|

|

| P.C. BOARD |

| Current | TERMINAL |

RPM |

CONTROL |

TEMP. |

GAUGE |

IDLER |

SWITCH |

ENGINE CONTROL UNIT (ECU)

OIL

GAUGE

|

|

|

|

|

| Max | Sensing |

|

| IDLER | TO |

|

|

| P.C. Board |

|

| SWITCH | BATTERY |

|

|

|

|

| ZENITH |

| TEMP. | OIL |

|

|

|

| THROTTLE | FUEL |

|

|

| ||

| GAUGE | GAUGE |

|

|

| ||

| BODY | INJECTORS |

|

|

|

|

|

|

|

|

| FUEL |

|

| |

RPM | CONTROLLER | FUEL |

|

|

|

| |

CONTROL |

| PUMP |

|

| PUMP |

|

|

|

|

|

|

| FUEL |

|

|

|

|

| TEMP. |

| SOLENOID |

|

|

|

| THROTTLE |

|

|

|

| |

|

| PLATE | SENSOR |

|

|

|

|

ENG. IGNITION |

| MOTOR | SWITCH | OIL |

|

|

|

|

|

|

|

|

| ||

|

|

| STARTER | SENSOR | ENGINE |

|

|

| OIL |

| SWITCH | SERIES | RESIDUAL | ||

| WATER | MOTOR |

| ||||

CIRCUITRY | GAUGE | GAUGE |

|

| IDLER | COILS | |

|

|

|

|

| SOLENOID | _ | MAGNETISM |

WATER |

| OIL |

|

|

| SHUNT |

TEMP. |

SENSOR |

SWITCH |

OIL

ENGINE ENGINE

SPEED SPEED

SENSOR ACTUATOR

& |

| PRESSURE & | PERKINS DIESEL | FIELD |

AIR TEMP. | MAP | WATER TEMP. | ENGINE | + |

SENSOR | SENSOR | SENSOR | ||

|

|

|

| GENERATOR |

Return to Section TOC

Return to Master TOC

| STARTER |

| MOTOR |

| START |

| RELAY |

ENGINE |

|

IGNITION |

|

SWITCH | ENGINE |

| ALTERNATOR |

SENSOR

SWITCHENGINE IGNITION SWITCH

KUBOTA | COUPLED TO |

DIESEL | GENERATOR |

ENGINE |

|

GLOW PLUGS

|

| ENGINE | MECHANICAL |

| & | ARMATURE | DC |

|

|

|

| ALTERNATOR | COUPLING | ARMATURE | SHAFT | EXCITER |

|

| |

|

|

| BRUSHES COMMUTATOR | ARMATURE |

|

| |||

| G.M. |

| GLOW PLUGS |

|

|

| - |

| |

STARTER | COUPLED TO |

|

| + |

|

| |||

MOTOR | GASOLINE |

|

|

|

|

|

| ||

|

|

|

|

| 15 AMP |

| |||

| ENGINE | GENERATOR |

|

|

|

| SERIES |

| |

|

|

|

| SHUNT | INTERPOLE |

| FIELD | FUSE |

|

|

|

|

| FIELD | COILS |

|

|

|

|

ENGINE |

|

|

| COILS |

|

|

|

|

|

ALTERNATOR |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| RECEPTACLE |

|

|

|

|

|

|

|

|

| 120VDC |

|

12 VOLT |

|

| 12 VOLT |

|

|

|

|

|

|

BATTERY |

|

| BATTERY |

|

|

|

|

|

|

|

|

|

|

|

| GENERATOR |

|

|

|

|

|

|

|

|

| FIELD CONTROL |

|

|

|

|

|

|

|

|

|

|

| + | POSITIVE |

|

|

|

|

|

|

|

| OUTPUT | |

|

|

|

|

|

|

|

|

| TERMINAL |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

GENERAL DESCRIPTION

The PIPELINER® 200 is a heavy duty, engine driven, DC arc welding power source capable of providing con- stant current output for stick welding or DC TIG weld- ing. Also, a total of 1750 watts of auxiliary power is available at the 120VDC receptacle. The PIPELINER® 200 is manufactured with all copper windings.