Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

|

| OPERATION |

|

|

|

|

|

|

|

|

|

| |||||||

CONTROL OF WELDING CURRENT |

|

|

| IDLER OPERATION |

|

|

|

|

|

|

| ||||||||

|

|

|

|

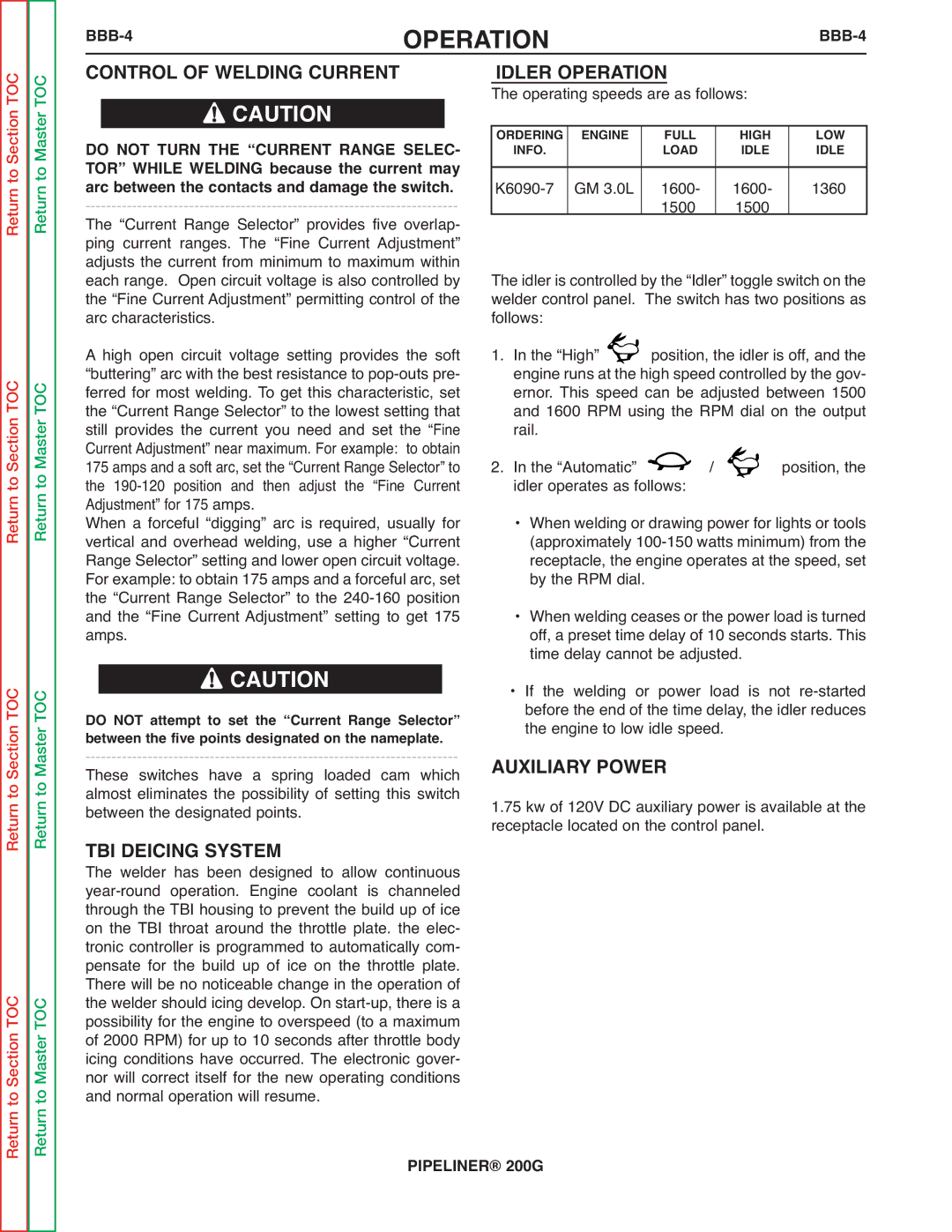

| The operating speeds are as follows: |

|

|

|

| ||||||||||

|

| CAUTION |

|

|

|

|

|

| |||||||||||

|

|

|

|

| ORDERING |

| ENGINE |

|

| FULL |

|

| HIGH |

|

| LOW |

| ||

DO NOT TURN THE “CURRENT RANGE SELEC- |

|

|

|

|

|

|

| ||||||||||||

|

| INFO. |

|

|

|

| LOAD |

|

| IDLE |

|

| IDLE |

| |||||

TOR” WHILE WELDING because the current may |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| GM 3.0L |

|

| 1600- |

|

| 1600- |

|

| 1360 |

| |||||||

arc between the contacts and damage the switch. |

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

| 1500 |

|

| 1500 |

|

|

|

| |||||

The “Current Range Selector” provides five overlap- |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

ping current ranges. The “Fine Current Adjustment” |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

adjusts the current from minimum to maximum within | The idler is controlled by the “Idler” toggle switch on the | ||||||||||||||||||

each range. Open circuit voltage is also controlled by | |||||||||||||||||||

the “Fine Current Adjustment” permitting control of the | welder control panel. The switch has two positions as | ||||||||||||||||||

arc characteristics. |

|

|

| follows: |

|

|

|

| position, the idler is off, and the | ||||||||||

A high open circuit voltage setting provides the soft | 1. | In the “High” | |||||||||||||||||

“buttering” arc with the best resistance to |

|

| engine runs at the high speed controlled by the gov- | ||||||||||||||||

ferred for most welding. To get this characteristic, set |

|

| ernor. This speed can be adjusted between 1500 | ||||||||||||||||

the “Current Range Selector” to the lowest setting that |

|

| and 1600 RPM using the RPM dial on the output | ||||||||||||||||

still provides the current you need and set the “Fine |

|

| rail. |

|

|

|

|

|

|

|

|

|

|

|

| ||||

Current Adjustment” near maximum. For example: to obtain | 2. | In the “Automatic” |

| / |

|

| position, the | ||||||||||||

175 amps and a soft arc, set the “Current Range Selector” to |

|

|

| ||||||||||||||||

the |

|

| idler operates as follows: |

|

|

|

|

|

|

| |||||||||

Adjustment” for 175 amps. |

|

|

|

| • When welding or drawing power for lights or tools | ||||||||||||||

When a forceful “digging” arc is required, usually for |

|

| |||||||||||||||||

vertical and overhead welding, use a higher “Current |

|

| (approximately | ||||||||||||||||

Range Selector” setting and lower open circuit voltage. |

|

| receptacle, the engine operates at the speed, set | ||||||||||||||||

For example: to obtain 175 amps and a forceful arc, set |

|

| by the RPM dial. |

|

|

|

|

|

|

|

| ||||||||

the “Current Range Selector” to the |

|

| • When welding ceases or the power load is turned | ||||||||||||||||

and the “Fine Current Adjustment” setting to get 175 |

|

| |||||||||||||||||

amps. |

|

|

|

|

| off, a preset time delay of 10 seconds starts. This | |||||||||||||

|

| CAUTION |

|

|

|

| time delay cannot be adjusted. |

|

|

|

| ||||||||

|

|

|

|

|

| • If the welding or power load is not | |||||||||||||

DO NOT attempt to set the “Current Range Selector” |

|

| before the end of the time delay, the idler reduces | ||||||||||||||||

between the five points designated on the nameplate. |

|

| the engine to low idle speed. |

|

|

|

|

| |||||||||||

AUXILIARY POWER |

|

|

|

|

|

|

| ||||||||||||

These switches have a spring loaded cam which |

|

|

|

|

|

|

| ||||||||||||

almost eliminates the possibility of setting this switch | 1.75 kw of 120V DC auxiliary power is available at the | ||||||||||||||||||

between the designated points. |

|

| |||||||||||||||||

TBI DEICING SYSTEM |

|

| receptacle located on the control panel. |

|

|

|

| ||||||||||||

The welder has been designed to allow continuous

PIPELINER® 200G