Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

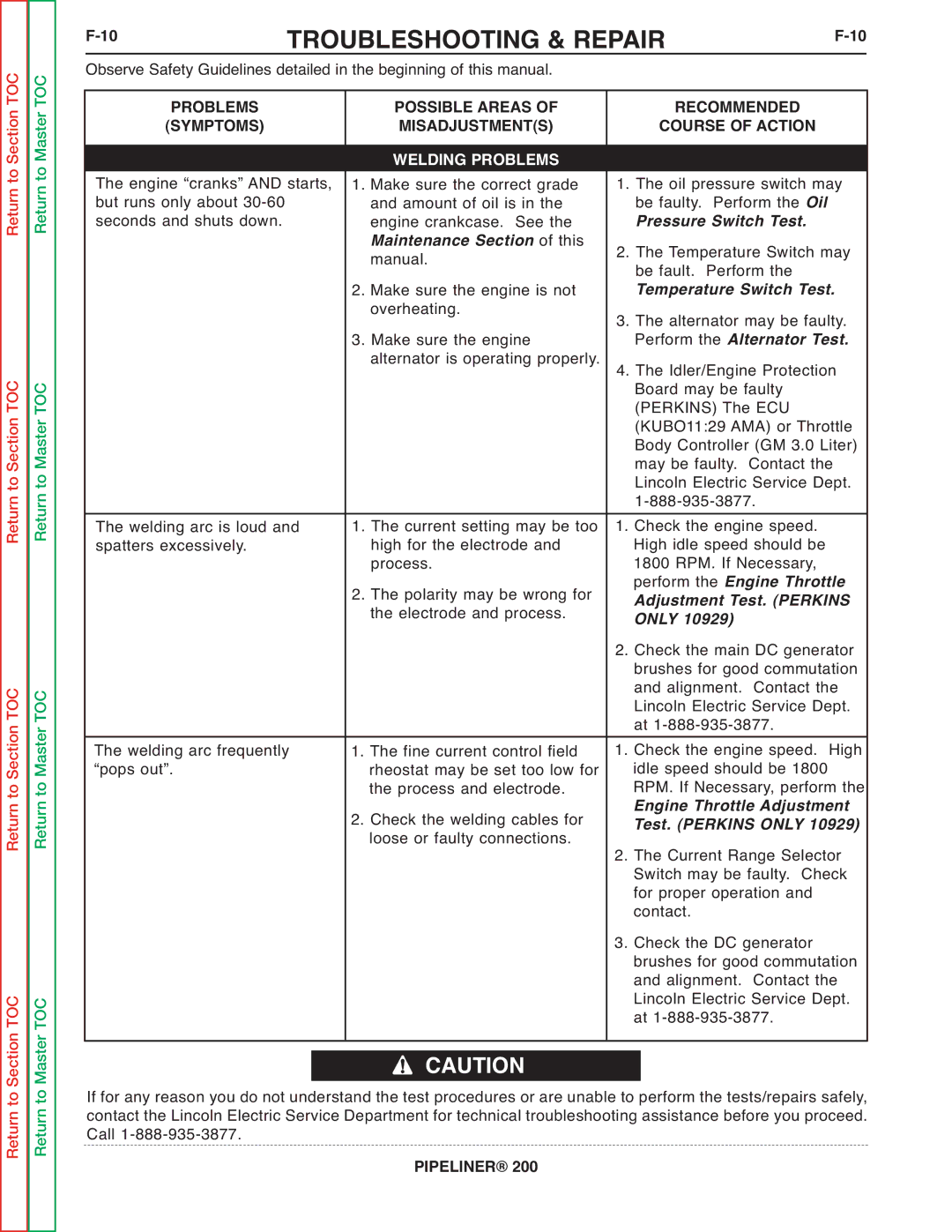

| TROUBLESHOOTING & REPAIR | ||||||

| Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

|

| ||

| PROBLEMS |

| POSSIBLE AREAS OF |

| RECOMMENDED |

|

|

|

|

|

|

| |||

| (SYMPTOMS) |

| MISADJUSTMENT(S) |

| COURSE OF ACTION |

| |

| The engine “cranks” AND starts, | WELDING PROBLEMS | 1. The oil pressure switch may |

| |||

|

| ||||||

| 1. Make sure the correct grade |

| |||||

|

| ||||||

| but runs only about |

| and amount of oil is in the | be faulty. Perform the | Oil |

| |

| seconds and shuts down. |

| engine crankcase. See the | Pressure Switch Test. |

| ||

|

|

| Maintenance Section of this | 2. The Temperature Switch may |

| ||

|

|

| manual. | be fault. Perform the |

|

| |

|

|

| 2. Make sure the engine is not | Temperature Switch Test. |

| ||

|

|

| overheating. | 3. The alternator may be faulty. |

| ||

|

|

| 3. Make sure the engine | Perform the Alternator Test. |

| ||

|

|

| alternator is operating properly. | 4. The Idler/Engine Protection |

| ||

|

|

|

| Board may be faulty |

|

| |

|

|

|

| (PERKINS) The ECU |

|

| |

|

|

|

| (KUBO11:29 AMA) or Throttle |

| ||

|

|

|

| Body Controller (GM 3.0 Liter) |

| ||

|

|

|

| may be faulty. Contact the |

| ||

|

|

|

| Lincoln Electric Service Dept. |

| ||

|

|

|

|

|

| ||

| The welding arc is loud and | 1. The current setting may be too | 1. Check the engine speed. |

| |||

| spatters excessively. |

| high for the electrode and | High idle speed should be |

| ||

|

|

| process. | 1800 RPM. If Necessary, |

| ||

|

|

| 2. The polarity may be wrong for | perform the Engine Throttle |

| ||

|

|

| Adjustment Test. (PERKINS |

| |||

|

|

| the electrode and process. | ONLY 10929) |

|

| |

|

|

|

| 2. Check the main DC generator |

| ||

|

|

|

| brushes for good commutation |

| ||

|

|

|

| and alignment. Contact the |

| ||

|

|

|

| Lincoln Electric Service Dept. |

| ||

|

|

|

| at |

|

| |

| The welding arc frequently | 1. The fine current control field | 1. Check the engine speed. High |

| |||

| “pops out”. |

| rheostat may be set too low for | idle speed should be 1800 |

| ||

|

|

| the process and electrode. | RPM. If Necessary, perform the |

| ||

|

|

| 2. Check the welding cables for | Engine Throttle Adjustment |

| ||

|

|

| Test. (PERKINS ONLY 10929) |

| |||

|

|

| loose or faulty connections. | 2. The Current Range Selector |

| ||

|

|

|

| Switch may be faulty. Check |

| ||

|

|

|

| for proper operation and |

| ||

|

|

|

| contact. |

|

| |

|

|

|

| 3. Check the DC generator |

| ||

|

|

|

| brushes for good commutation |

| ||

|

|

|

| and alignment. Contact the |

| ||

|

|

|

| Lincoln Electric Service Dept. |

| ||

|

|

|

| at |

|

| |

|

|

| CAUTION |

|

|

|

|

| If for any reason you do not understand the test procedures or are unable to | perform the tests/repairs safely, | |||||

| contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. | ||||||

| Call |

|

|

|

|

|

|