Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

F-34 TROUBLESHOOTING & REPAIRF-34

CURRENT SENSOR PCB TEST (CONTINUED)

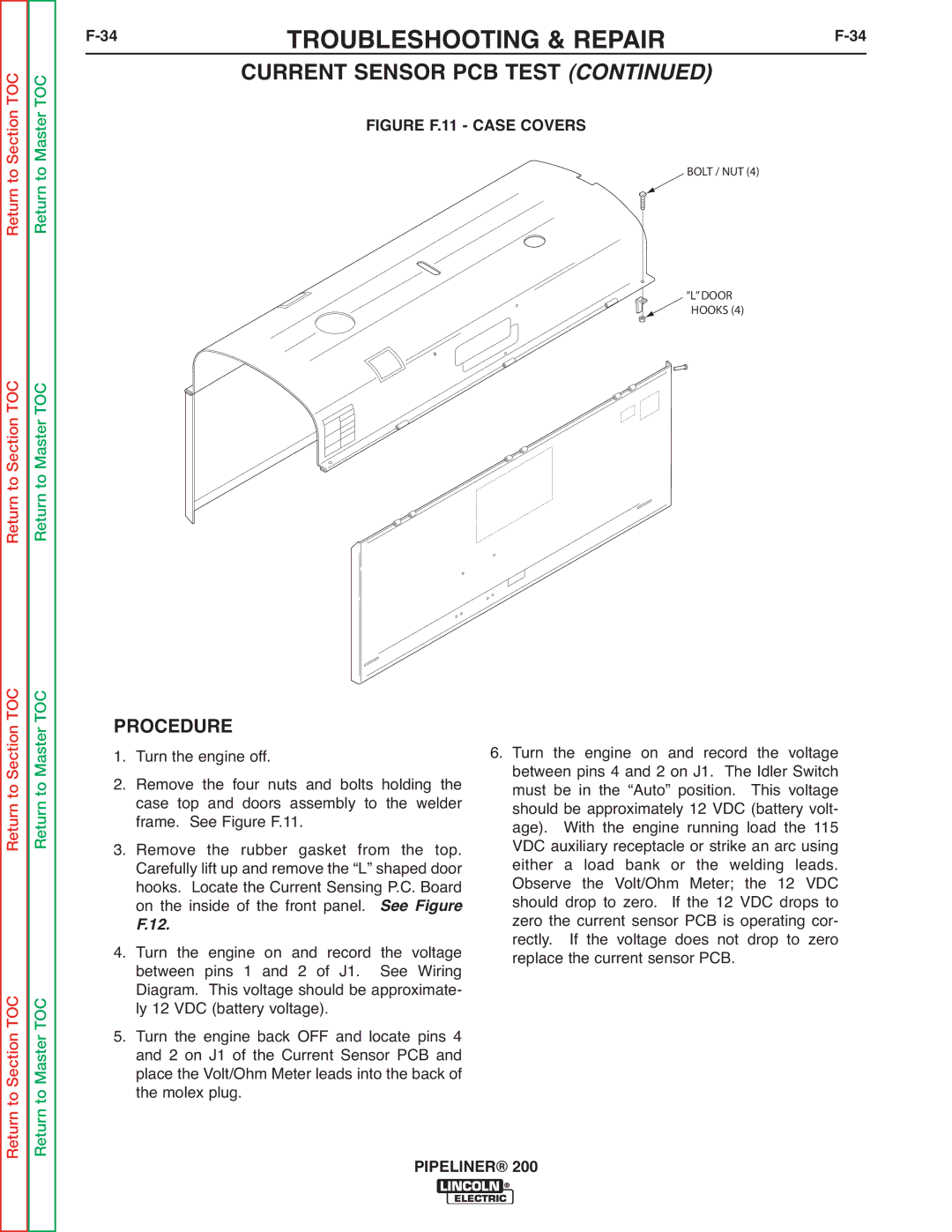

FIGURE F.11 - CASE COVERS

BOLT / NUT (4)

“L”DOOR HOOKS (4)

Return to Section TOC

to Section TOC

Return to Master TOC

Return to Master TOC

PROCEDURE

1. Turn the engine off.

2. Remove the four nuts and bolts holding the case top and doors assembly to the welder frame. See Figure F.11.

3. Remove the rubber gasket from the top. Carefully lift up and remove the “L” shaped door hooks. Locate the Current Sensing P.C. Board on the inside of the front panel. See Figure

F.12.

4. Turn the engine on and record the voltage between pins 1 and 2 of J1. See Wiring Diagram. This voltage should be approximate- ly 12 VDC (battery voltage).

5. Turn the engine back OFF and locate pins 4 and 2 on J1 of the Current Sensor PCB and place the Volt/Ohm Meter leads into the back of the molex plug.

6.Turn the engine on and record the voltage between pins 4 and 2 on J1. The Idler Switch must be in the “Auto” position. This voltage should be approximately 12 VDC (battery volt- age). With the engine running load the 115 VDC auxiliary receptacle or strike an arc using either a load bank or the welding leads. Observe the Volt/Ohm Meter; the 12 VDC should drop to zero. If the 12 VDC drops to zero the current sensor PCB is operating cor- rectly. If the voltage does not drop to zero replace the current sensor PCB.

Return