Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

| MAINTENANCE | ||||

SAFETY PRECAUTIONS |

|

| beneath the gas tank and clean out any accumulat- | ||

| WARNING |

|

| 4. When necessary, remove the sediment bowl from | |

|

|

| ed dirt and water. Replace the fuel filter in the fuel | ||

Have qualified personnel do the maintenanc | e | line as needed. |

| ||

work. Turn the engine off before working inside | 5. See the engine manufacturers operation manual for | ||||

the machine. In some cases, it may be necessary | |||||

to remove safety guards to perform required | detailed engine maintenance and troubleshooting | ||||

maintenance. Remove guards only when neces- | instructions. |

| |||

sary and replace them when the maintenance | COOLING SYSTEM |

| |||

requiring their removal is complete. Always use |

| ||||

the greatest care when working near moving | The Pipeliner® 200D is equipped with a pressure radi- | ||||

parts. |

|

|

| ator. Keep the radiator cap tight to prevent loss of | |

Do not put your hands near the engine cooling | coolant. Clean and flush the cooling system periodical- | ||||

blower fan. If a problem cannot be corrected by | ly to prevent clogging the passage and overheating the | ||||

following the instructions, take the machine to | engine. When antifreeze is needed, always use the | ||||

the nearest Lincoln Field Service Shop. | permanent type. |

| |||

ENGINE MAINTENANCE |

| ||||

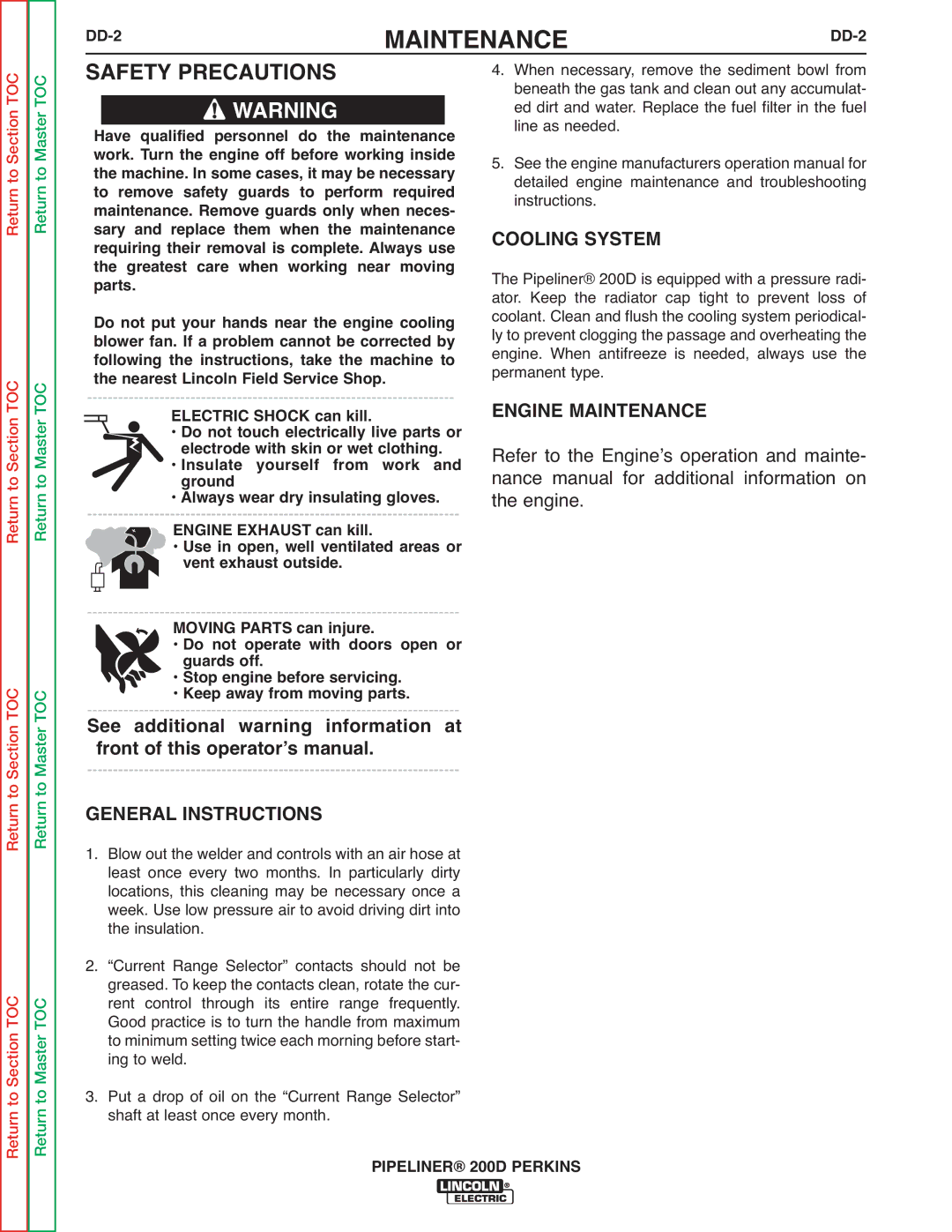

| ELECTRIC SHOCK can kill. |

|

|

| |

| • Do not touch electrically live parts or | Refer to the Engineʼs operation and mainte- | |||

| • Insulateelectrode withyourselfskin orfromwet clothing.work and | ||||

| ground |

|

| nance manual for additional information on | |

| • Always wear dry insulating gloves. | the engine. |

| ||

| |||||

| ENGINE EXHAUST can kill. |

|

|

|

|

| • Use in open, well ventilated areas or |

|

| ||

| vent exhaust outside. |

|

|

|

|

MOVING PARTS can injure.

• Do not operate with doors open or guards off.

• Stop engine before servicing.

![]() • Keep away from moving parts.

• Keep away from moving parts.

front of this operatorʼs manual.

GENERAL INSTRUCTIONS

1.Blow out the welder and controls with an air hose at least once every two months. In particularly dirty locations, this cleaning may be necessary once a week. Use low pressure air to avoid driving dirt into the insulation.

2.“Current Range Selector” contacts should not be greased. To keep the contacts clean, rotate the cur- rent control through its entire range frequently. Good practice is to turn the handle from maximum to minimum setting twice each morning before start- ing to weld.

3.Put a drop of oil on the “Current Range Selector” shaft at least once every month.