SX6T/SX8T Series

Table of Contents

Printer Parameter Fine Adjustment

Test Print

Program Down Load

On Line Mode

Rfid Analyze Tool

Introduction

Key Operation Flow

Operation Panel

This is the start of the IP Address Setting menu. → Section

→ Section

8BASIC Pause

This is the start of the Basic Setting menu

This is the Rfid Module Setting menu

10RFID Pause

„ How to Enter Self-diagnostic Test Mode

Self-diagnostic Test

„ Outline of Self-diagnostic Test

PRT Type Transfr

PRT Type no Tran

Printing Mode Selection

Dispensing Mode Selection

PRT Type Direct

Maintenance Counter/Parameter Settings Print Out

Maintenance Checking & Print

Stabilizer Auto Calib OFF LAN On Snmp on Prtr IP Address

Descriptions of the Maintenance Counter

Descriptions of the Parameters

Font

¶¶-¶¶-¶¶-¶¶-¶¶-¶¶

Basic

Print Sample

Self-Diagnostic Test and Result Print Out

After printing is completed, the display returns to 1DIAG

Kanji ROM Check

Descriptions

Alphanumeric Font ROM Check

Eeprom Check

Sensor/Switch Print status description

Sdram Capacity

Sensor 2 Check

Sensor/Thermistor

Manual Threshold Check

=300 GNDhms

Rfid module check Results of a Rfid module check is printed

Internal Serial Interface Check

DIN

Print Head Element Check

Press the Pause key to return to 1DIAG

Parameter Setting

Outline of Parameter Setting

Use the Feed or Restart key to select a desired option

How to Enter Parameter Setting Mode

Character Code Selection

After selecting a character code, press the Pause key

After selecting a character zero, press the Pause key

Character Zero Selection

Baud Rate Selection

After selecting a baud rate, press the Pause key

After selecting a data length, press the Pause key

Data Length Selection

Stop Bit Length Selection

After selecting a stop bit, press the Pause key

Flow Control Code Selection

Parity Selection

After selecting the parity, press the Pause key

Auto Forward Wait Selection

LCD Language Selection

After selecting a language, press the Pause key

Head Up Cut Selection

Ribbon Save Function Selection

Code Auto Code ESC,LF,NUL Code Manual

Control Code Selection

2PARAMETER SET Code Auto

2PARAMETER SET Control CODE1 1B

After selecting a ribbon type, press the Pause key

Ribbon Type Selection

Strip Wait Status Selection

After selecting the Strip Wait Status, press the Pause key

Kanji Code Selection

Feed Key Function Selection

Euro Code Selection

After selecting auto print head check, press the Pause key

Auto Print Head Check Selection

Centronics Interface ACK/BUSY Timing Selection

After selecting an ACK/BUSY timing, press the Pause key

Media Sensor Selection

Web Printer Function Selection

After selecting the media sensor type, press the Pause key

Expansion I/O Interface Type Selection

Input Prime Selection

After selecting the Input Prime, press the Pause key

Label End/Ribbon End Selection

Plug & Play Selection

After selecting a Plug & Play, press the Pause key

TYPE1

Reverse Feed Speed Selection

Maxi Code Specification Selection

Pre-Strip Selection

Press the Pause key to skip

2PARAMETER SET Peel OFF TRQ R0

Strip Motor Torque Selection

Stabilizer Function Selection

2PARAMETER SET Stabilizer on

Printer Parameter Fine Adjustment

Outline of Printer Parameter Fine Adjustment

How to Enter Printer Parameter Fine Adjustment Mode

3ADJUST SET

After completing the fine adjustment, press the Pause key

Print Start Position Fine Adjustment

Print Start Position Fine Adjustment Example

Example of Cut Position Fine Adjustment

2 Cut/Strip Position Fine Adjustment

When setting +0.0 mm

Prevention by fine adjustment of the cut position

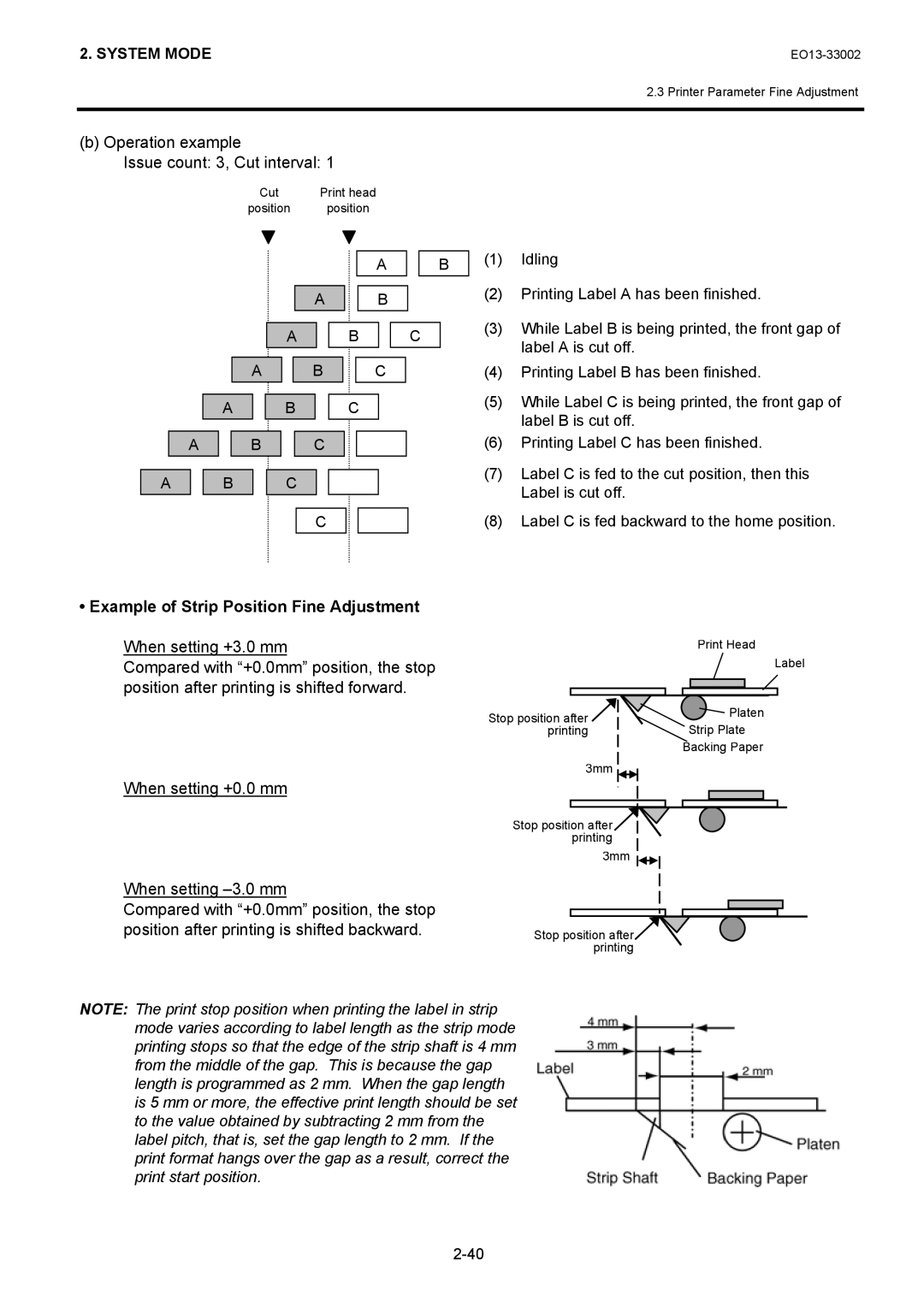

Operation example Issue count 3, Cut interval

Example of Strip Position Fine Adjustment

Reverse Feed Amount Fine Adjustment

Example of Reverse Feed Amount Fine Adjustment

Coordinate Fine Adjustment

Example of X Coordinate Fine Adjustment

Maximum fine adjustment value

Darker Standard Lighter

Ribbon Motor Voltage Fine Adjustment Feed/Take-up Motor

High Standard Low

3ADJUST SET THRESHOLDR1.0V

Threshold Manual Fine Adjustment Black Mark/Feed Gap Sensor

3ADJUST SET THRESHOLDT1.4V

Test Print

Outline of Test Print

Media Ribbon Save Area 8 mm

How to Enter Test Print Mode

4TEST Print

Print Speed Setting

Issue Count Setting

Select an issue count from a range of 1 to

Specifying the Print Condition for the Test Print

Issue Mode Selection

Printing Mode Selection

Sensor Type Selection

Paper Feed Selection

Media Length Setting

4TEST Print Paper Feed

Test Print Pattern Selection

Slant Line 1 dot

Slant Line 3 dots

Print Sample of Slant Line 3 dots

Print Sample of Characters

Characters

Barcode

Print Sample of Barcodes

Print Sample of Non-print

Non-Printing

Factory Test

Print Sample of Factory Test

Prints bar codes on 5 pieces of media

Auto Print

Pause key

Prints characters on 5 pieces of media

Sensor Adjustment

Outline of the Sensor Adjustment

Thermistor Status Display

Black Mark Sensor Adjustment

How to Enter the Sensor Adjustment Mode

5SENSOR ADJ

Press the Pause key to return to 5SENSOR ADJ. display

Feed Gap Sensor Adjustment

Ribbon End Sensor Adjustment Ribbon Level

5SENSOR ADJ. Trans

Outline of RAM Clear

How to Enter RAM Clear Mode

RAM Clear

6RAM Clear

No RAM Clear

Maintenance Counter Clear

RAM Clear Menu Selection

SX6T-TS12-QM-R and B-SX8T-TS12-QM-R V1.0B or earlier

Solenoid drive time for head up

Parameter Clear

Mode

Initial values after clearing the parameters Parameter Clear

170.6 mm

How to Enter IP Address Setting Mode

IP Address Setting

Outline of the IP Address Setting

7IP Address

To enter each sub menu, press the Pause key

When Printer IP Adres is displayed, press the Pause key

Set the IP address using the following procedure

Printer IP Adres

Dhcp and Dhcp Client ID Setting

Socket Port Setting

To set a socket port number, follow the procedure below

Mode Ascii

Dhcp Host Name Setting

Mode Ascii Dhcp Host Name

Ascii code and Hex. code correspondence table

Outline of Basic Setting

Basic Setting

How to Enter Basic Setting Mode

8BASIC

Basic Trace Selection Mode

Basic Specification Selection Mode

Basic File Browser

Basic Expansion Mode Execution of Basic Program

Rfid Module Setting

Outline of the Rfid Module Setting

Rfid Read Test

How to Enter Rfid Module Setting Mode

Read Test Procedure

Press the Restart key or Feed key until 10RFID appears

Module None

Rfid Module Type Selection

Module None Module U2

Rfid Error Tag Detection

Rfid Tag Type Selection

Maximum Number of Rfid Issue Retries

Issue Retry

Maximum Number of Rfid Read Retries

Cycle CNT

After selecting the time-out, press the Pause key

Rfid Read Retry Time-out

Cycle TIM

Maximum Number of Rfid Write Retries

Rfid Write Retry Time-out

Adjustment in positive + direction

Rfid Adjustment for Retry

Adjustment in negative − direction

After selecting the adjustment value, press the Pause key

Power Level

Rfid Wireless Power Level Setting

When AGC Threshold is displayed, press the Pause key

Rfid AGC Threshold

Value

Rfid Module Q Value Setting

Qvalue

When WT AGC is displayed, press the Pause key

AGC Threshold for Data Write Setting

WT AGC

AGC Threshold Lower Limit for Retry Setting

WT MIN AGC

On Line Mode

Symbols in the message

„ LCD message and LED indication

System Error

Rfid Write Error

„ Outline of Automatic Threshold Setting

Automatic Threshold Setting

„ How to Perform an Automatic Threshold Setting

„ How to Perform a Reset Operation

Reset Operation

1RESET

Dump Mode

„ How to Perform a Dump Operation

Receive buffer size

Data in the receive buffer is printed as follows

Print Conditions

Required label length

„ How to Perform Basic Expansion

Basic Expansion Mode

5EXPAND Mode

6AUTO Calib

Automatic Calibration Setting

„ How to Choose an Automatic Calibration Setting

6AUTO Calib OFF

On Line Mode

„ How to Enable/Disable the LAN

LAN Enable/Disable Setting

On Snmp on

8RTC SET

Real Time Clock RTC Setting

„ How to perform the Real Time Clock Setting

8RTC SET Date M

8RTC SET Time S

8RTC SET Time H

8RTC SET Time M

8RTC SET LOW BATT. Check

On Line Mode

Download Program Installation

Outline of Features

System Requirements

Installation Procedure

Setup

Setup Disk

Before starting the download procedure

First, start the printer in download mode

EO13-33002

Program Down Load

Program Down Load

Program Down Load

Rfid Analyze Tool

System Requirement

SX/SA Rfid Analyze Tool

Set up

Setup Disk Installation Setup Disk consists of one CD-ROM

V1.5

U2 B-SX704-RFID-U2-EU/AU/US/CN-R

Application Functions

Main Menu

SX708-RFID-U2-EU/CN-R

File Menu

EO13-33002

End Exit Exits from the Analyze Tool program

Tool Menu

NON, XON, XON/XOFF

PWR Level Change AGC Read Value

Sheet Setting Makes settings for the media to be used

Select the test mode This menu is not available

Select the printer model

Example

Help Menu

Displays Printer Version and Rfid Module Version

Operating Procedure

Click on the Tool menu, and choose CommSetting

RTS/CTS+XON/XOFF

SX704-RFID-U2-EU/AU/US/CN-R U2

Tag Data

U2 B-SA704-RFID-U2-EU/AU/US/CN-R B-SX708-RFID-U2-EU/CN-R

EO13-33002 Revision Date Jul Operatin Procedure

Write/Read Results Box When U2 is selected

Write/Read Results Box

![]()

![]()

![]()

![]()

![]()

![]()