Hydraulic Motor Applications

The hydraulic system is a load sensing, pressure and flow compensating system.. Pressure and flow are regulated by a load sensing line from the implement valve.. For proper and efficient use of the system, low volume open center hydraulic motors or closed center system motors with restricting orifices removed and bypass valve closed should be used.. Motor speed must be regulated with tractor implement valve flow control rather than bypass valves and orifices at the motor.. This will reduce heat buildup, save oil for other simultaneous operations of the implement valve, and increase system reliability..

1.Use hydraulic motors designed for closed center or pressure/flow load compensating hydraulic systems only.. Do not use a hydraulic motor designed for open center hydraulic systems unless it is adapted for use by removing the inlet restrictor..

2.Be sure the hydraulic motor does not have restrictors in the ports or fittings..

3.Hydraulic motors rated at less than 37..85 L/min (10 US GPM) may be equipped with 12mm (1/2") ID hoses and standard (ASAE/SAE/ISO) couplers..

4.Hydraulic motors rated at greater than 10 US GPM (37..85 L/min) should be connected with 19 mm (3/4") hoses and (ASAE/SAE/ISO) couplers to prevent excessive restriction and heat generation..

Low Pressure Return Circuit - Case Drain

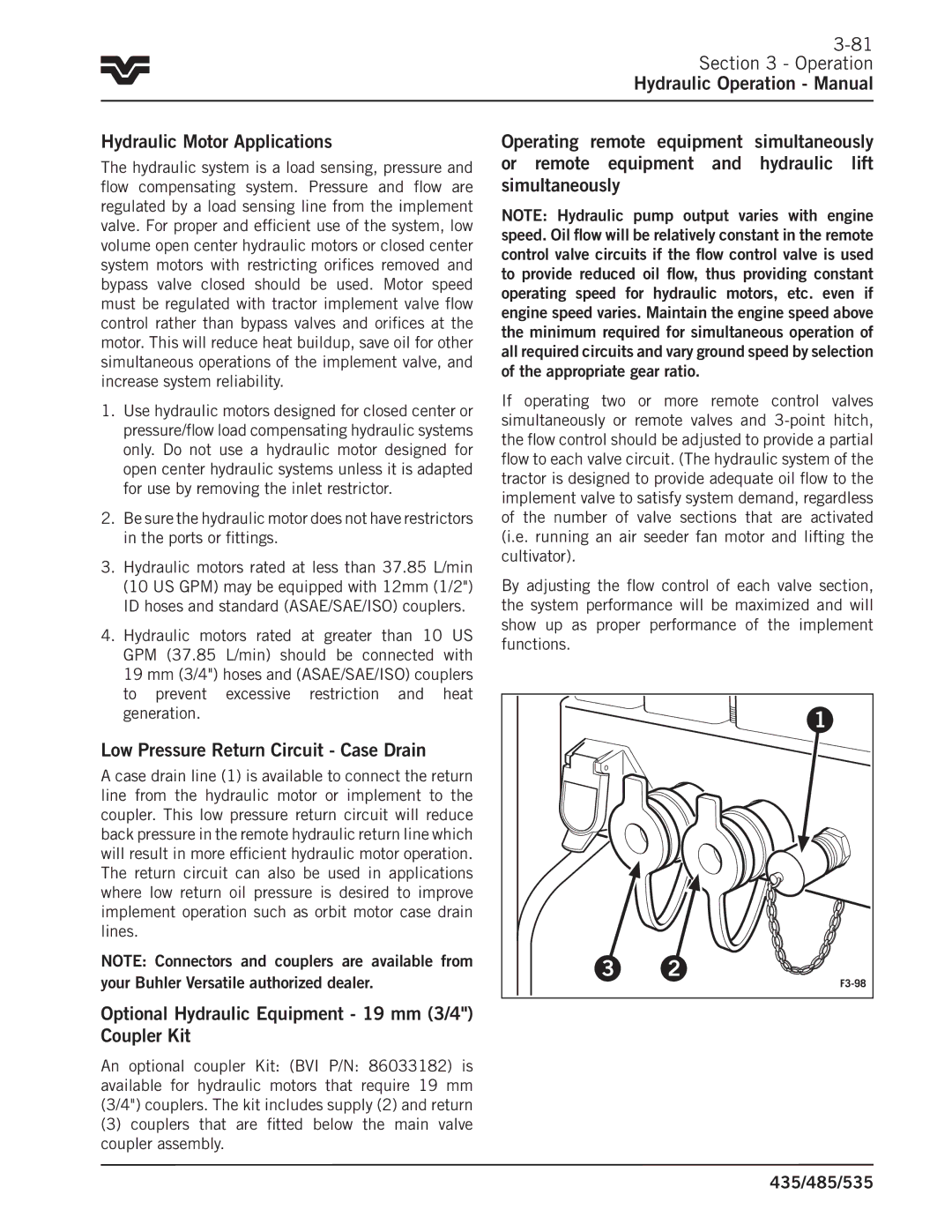

A case drain line (1) is available to connect the return line from the hydraulic motor or implement to the coupler.. This low pressure return circuit will reduce back pressure in the remote hydraulic return line which will result in more efficient hydraulic motor operation.. The return circuit can also be used in applications where low return oil pressure is desired to improve implement operation such as orbit motor case drain lines..

NOTE: Connectors and couplers are available from your Buhler Versatile authorized dealer.

Operating remote equipment simultaneously or remote equipment and hydraulic lift simultaneously

NOTE: Hydraulic pump output varies with engine speed. Oil flow will be relatively constant in the remote control valve circuits if the flow control valve is used to provide reduced oil flow, thus providing constant operating speed for hydraulic motors, etc. even if engine speed varies. Maintain the engine speed above the minimum required for simultaneous operation of all required circuits and vary ground speed by selection of the appropriate gear ratio.

If operating two or more remote control valves simultaneously or remote valves and

By adjusting the flow control of each valve section, the system performance will be maximized and will show up as proper performance of the implement functions..

| 1 |

3 | 2 |

|

Optional Hydraulic Equipment - 19 mm (3/4") Coupler Kit

An optional coupler Kit: (BVI P/N: 86033182) is available for hydraulic motors that require 19 mm (3/4") couplers.. The kit includes supply (2) and return

(3)couplers that are fitted below the main valve coupler assembly..