Section 4 - Lubrication & Maintenance

Every 500 Hours

Operation 48

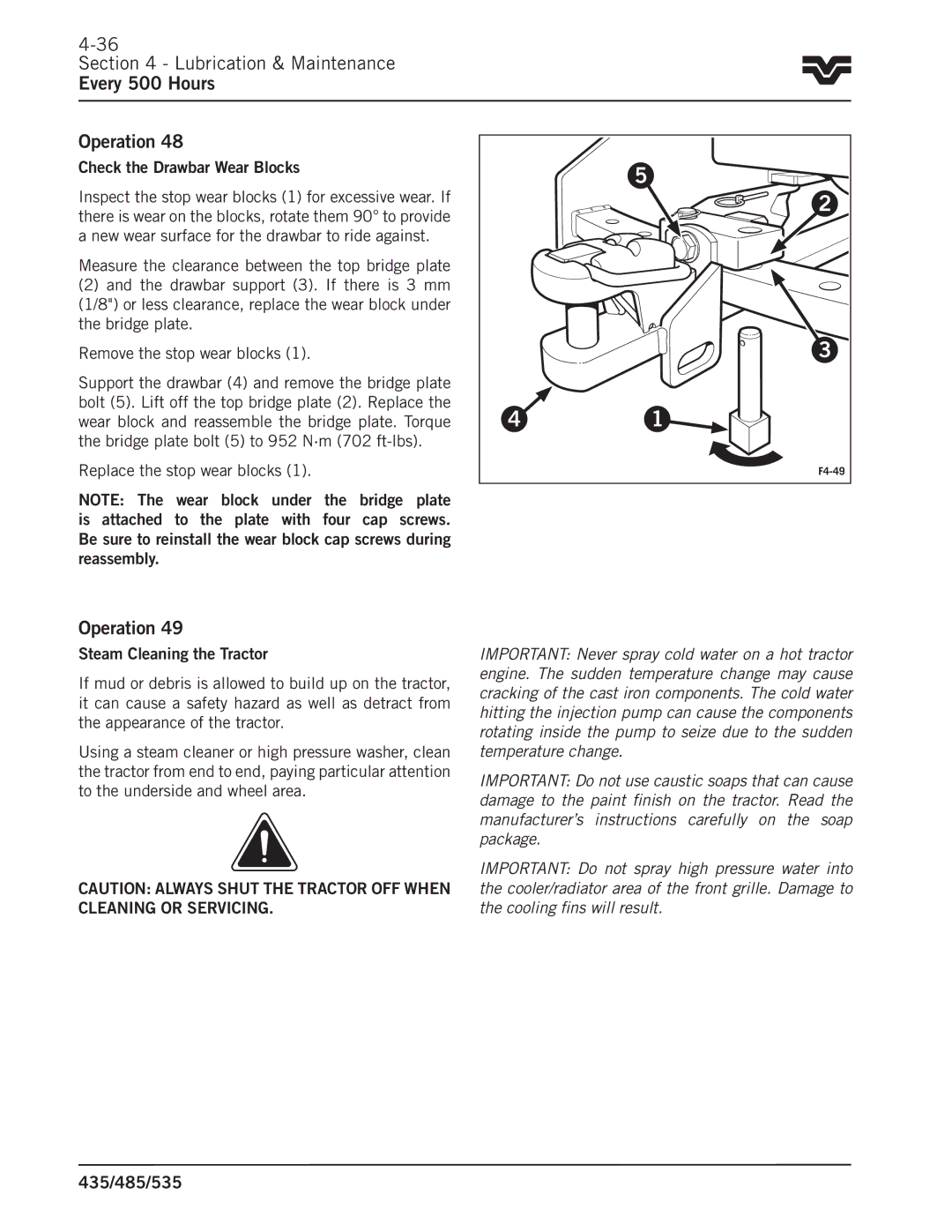

Check the Drawbar Wear Blocks

Inspect the stop wear blocks (1) for excessive wear.. If there is wear on the blocks, rotate them 90° to provide a new wear surface for the drawbar to ride against..

Measure the clearance between the top bridge plate

(2)and the drawbar support (3).. If there is 3 mm (1/8") or less clearance, replace the wear block under the bridge plate..

Remove the stop wear blocks (1)..

Support the drawbar (4) and remove the bridge plate bolt (5).. Lift off the top bridge plate (2).. Replace the wear block and reassemble the bridge plate.. Torque the bridge plate bolt (5) to 952 N·m (702

Replace the stop wear blocks (1)..

NOTE: The | wear block | under | the | bridge plate |

is attached | to the plate | with | four | cap screws. |

Be sure to reinstall the wear block cap screws during reassembly.

| 5 |

| 2 |

| 3 |

4 | 1 |

|

Operation 49

Steam Cleaning the Tractor

If mud or debris is allowed to build up on the tractor, it can cause a safety hazard as well as detract from the appearance of the tractor..

Using a steam cleaner or high pressure washer, clean the tractor from end to end, paying particular attention to the underside and wheel area..

CAUTION: ALWAYS SHUT THE TRACTOR OFF WHEN CLEANING OR SERVICING.

IMPORTANT: Never spray cold water on a hot tractor engine. The sudden temperature change may cause cracking of the cast iron components. The cold water hitting the injection pump can cause the components rotating inside the pump to seize due to the sudden temperature change.

IMPORTANT: Do not use caustic soaps that can cause damage to the paint finish on the tractor. Read the manufacturer’s instructions carefully on the soap package.

IMPORTANT: Do not spray high pressure water into the cooler/radiator area of the front grille. Damage to the cooling fins will result.