4-23 Section 4 - Lubrication & Maintenance

Every 250 Hours

Operation 25

Change the Fuel Filter

WARNING: FUEL IS FLAMMABLE. KEEP ALL CIGARETTES, FLAMES, PILOT LIGHTS, WELDING EQUIPMENT, AND SWITCHES OUT OF THE WORK AREA AND AREAS SHARING VENTILATION TO AVOID SEVERE PERSONAL INJURY OR DEATH WHEN WORKING ON THE FUEL SYSTEM.

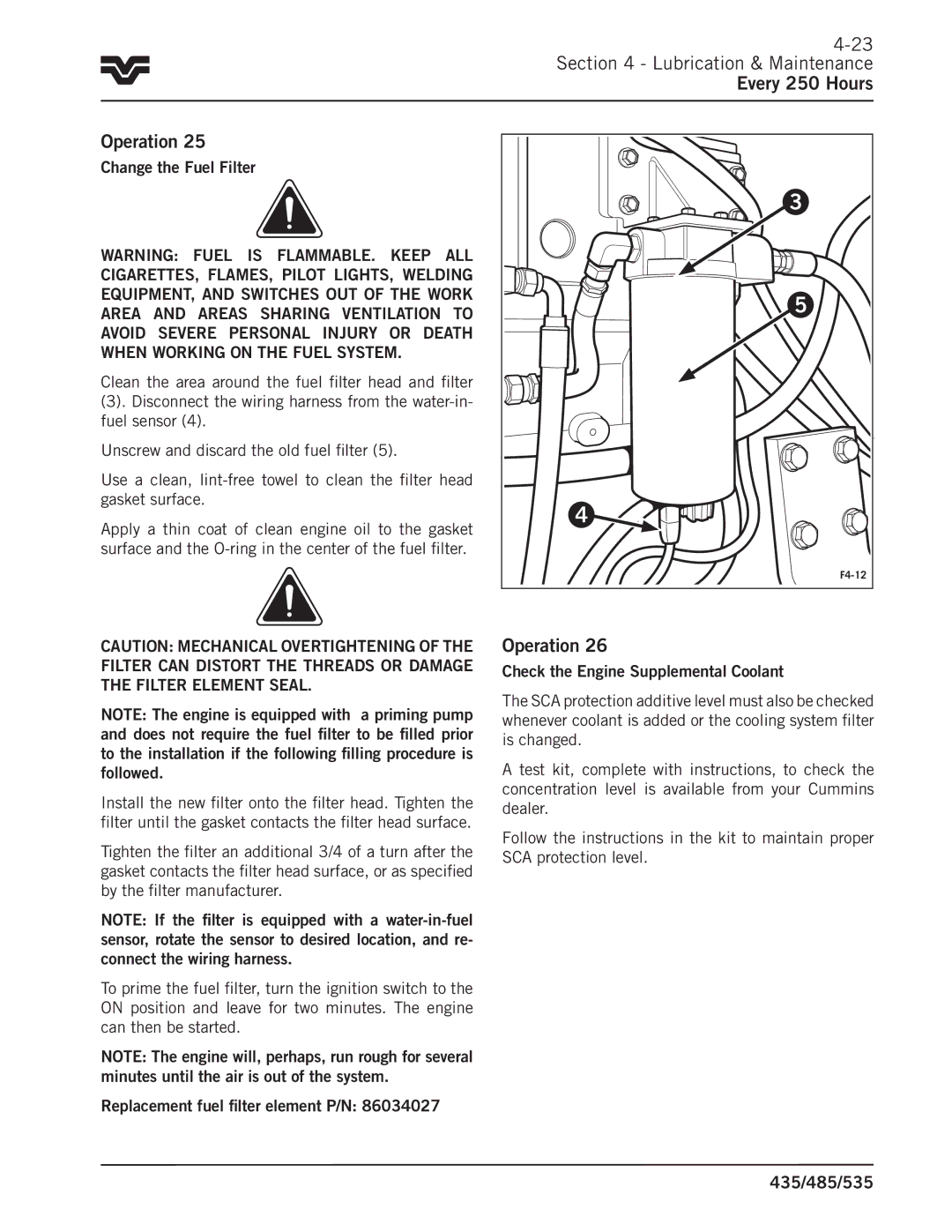

Clean the area around the fuel filter head and filter

(3).. Disconnect the wiring harness from the

Unscrew and discard the old fuel filter (5)..

Use a clean,

Apply a thin coat of clean engine oil to the gasket surface and the

3 |

5 |

4 |

CAUTION: Mechanical overtightening of the filter can distort the threads or damage the filter element seal.

NOTE: The engine is equipped with a priming pump and does not require the fuel filter to be filled prior to the installation if the following filling procedure is followed.

Install the new filter onto the filter head.. Tighten the filter until the gasket contacts the filter head surface..

Tighten the filter an additional 3/4 of a turn after the gasket contacts the filter head surface, or as specified by the filter manufacturer..

NOTE: If the filter is equipped with a

To prime the fuel filter, turn the ignition switch to the ON position and leave for two minutes.. The engine can then be started..

NOTE: The engine will, perhaps, run rough for several minutes until the air is out of the system.

Replacement fuel filter element P/N: 86034027

Operation 26

Check the Engine Supplemental Coolant

The SCA protection additive level must also be checked whenever coolant is added or the cooling system filter is changed..

A test kit, complete with instructions, to check the concentration level is available from your Cummins dealer..

Follow the instructions in the kit to maintain proper SCA protection level..