3-57 Section 3 - Operation

Transmission Operation

Transmission Operation

Synchromesh Transmission Operation

The Synchromesh transmission has three forward ranges and one reverse range.. Within each range, including reverse, there are four synchronized speeds.. The synchronized speeds allow for easier shifting within each range.. This combination allows for twelve forward speeds and four reverse speeds..

All shifting is done manually, in conjunction with the clutch.. The transmission incorporates a shaft brake, which is designed to stop transmission rotation when shifting between ranges.. This is activated when the range lever is in neutral and the clutch pedal is fully depressed..

IMPORTANT: Engage the clutch at a low throttle setting and as light a draft load as possible to extend clutch and synchronizer life. Do not engage the clutch when the throttle is set higher than 1700 RPM while under load. Raise the implement whenever possible during shifting.

Use the decelerator pedal to bring the engine speed down when shifting or engaging the clutch..

All gears in the transmission are constantly in mesh.. When a range is selected, shift collars splined to the shafts are being engaged with the range gears.. The tractor must be at full stop in order to shift between ranges.

The transmission bearings and gears are pressure lubricated.. The lubrication circuit consists of a gear pump located on and driven by the transmission, an oil cooler located in front of the engine radiator, a filter located inside the frame at the front of the tractor, and the oil distribution manifold on the transmission.. The transmission case acts as a reservoir..

Should the transmission oil pressure warning lamp come on, (page

CAUTION: KEEP THE CAB FLOOR AREA FREE FROM DEBRIS OR OBJECTS WHICH MAY OBSTRUCT THE OPERATION OF THE CLUTCH PEDAL. KEEP THE PEDAL CLEAN AND DRY TO PREVENT YOUR FOOT FROM SLIPPING OFF THE PEDAL, CAUSING ABRUPT ENGAGEMENT.

Range Shifting

1.Be sure the engine speed is below 1700 RPM.. Whenever possible, reduce engine speed to idle..

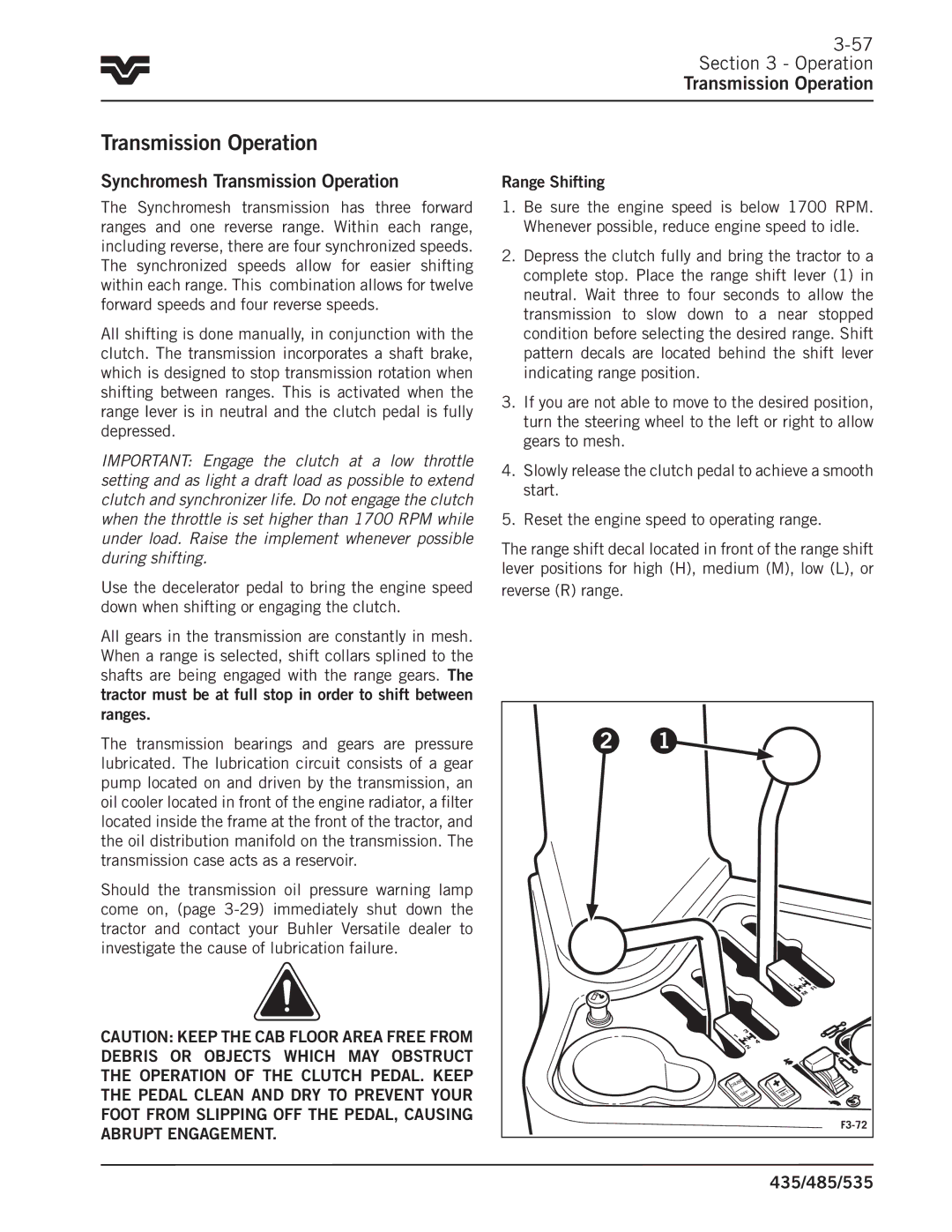

2.Depress the clutch fully and bring the tractor to a complete stop.. Place the range shift lever (1) in neutral.. Wait three to four seconds to allow the transmission to slow down to a near stopped condition before selecting the desired range.. Shift pattern decals are located behind the shift lever indicating range position..

3.If you are not able to move to the desired position, turn the steering wheel to the left or right to allow gears to mesh..

4.Slowly release the clutch pedal to achieve a smooth start..

5.Reset the engine speed to operating range..

The range shift decal located in front of the range shift lever positions for high (H), medium (M), low (L), or

reverse (R) range..

2 | 1 |

|

|

|

|

| H |

|

|

| L |

|

|

| N R |

|

|

| M |

|

| 3 |

|

| 1 | N |

|

|

| 4 | |

|

|

| |

|

| 2 |

|

| CRUISE |

| |

|

| OFF | (SET) |

|

|

| |

|

|

| 435/485/535 |