4-27 Section 4 - Lubrication & Maintenance

Every 250 Hours

Operation 32

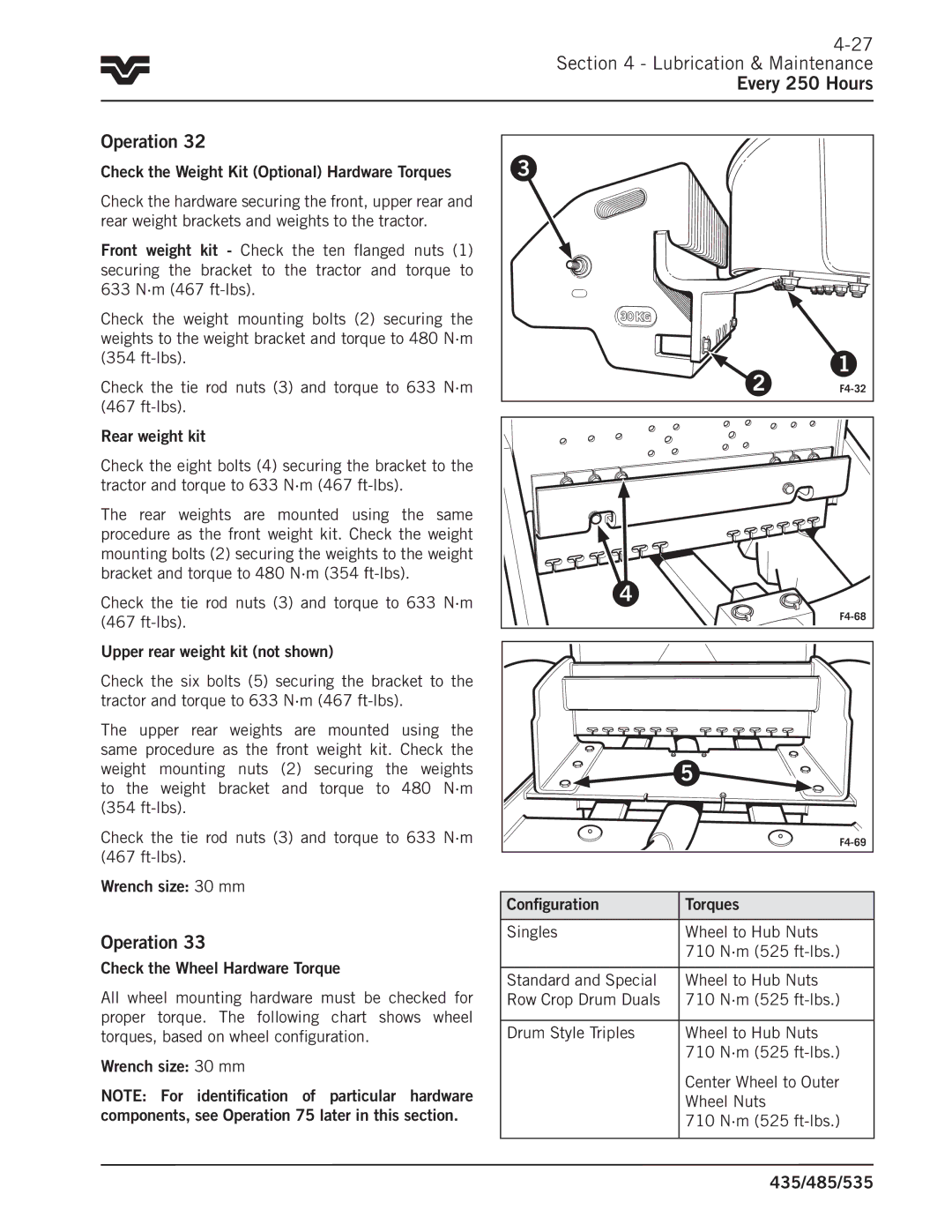

Check the Weight Kit (Optional) Hardware Torques

Check the hardware securing the front, upper rear and rear weight brackets and weights to the tractor..

Front weight kit - Check the ten flanged nuts (1) securing the bracket to the tractor and torque to 633 N·m (467

Check the weight mounting bolts (2) securing the weights to the weight bracket and torque to 480 N·m (354

Check the tie rod nuts (3) and torque to 633 N·m (467

Rear weight kit

Check the eight bolts (4) securing the bracket to the tractor and torque to 633 N·m (467

The rear weights are mounted using the same procedure as the front weight kit.. Check the weight mounting bolts (2) securing the weights to the weight bracket and torque to 480 N·m (354

Check the tie rod nuts (3) and torque to 633 N·m (467

Upper rear weight kit (not shown)

Check the six bolts (5) securing the bracket to the tractor and torque to 633 N·m (467

The upper rear weights are mounted using the same procedure as the front weight kit.. Check the weight mounting nuts (2) securing the weights to the weight bracket and torque to 480 N·m (354

Check the tie rod nuts (3) and torque to 633 N·m (467

Wrench size: 30 mm

Operation 33

Check the Wheel Hardware Torque

All wheel mounting hardware must be checked for proper torque.. The following chart shows wheel torques, based on wheel configuration..

Wrench size: 30 mm

NOTE: For identification of particular hardware components, see Operation 75 later in this section.

3 |

2 | 1 |

4 |

|

|

| 5 |

| |

Configuration | Torques |

Singles | Wheel to Hub Nuts |

| 710 N·m (525 |

|

|

Standard and Special | Wheel to Hub Nuts |

Row Crop Drum Duals | 710 N·m (525 |

|

|

Drum Style Triples | Wheel to Hub Nuts |

| 710 N·m (525 |

| Center Wheel to Outer |

| Wheel Nuts |

| 710 N·m (525 |