Section 3 - Operation

Hydraulic Operation - Manual

Operating Continuous Flow Hydraulic Equipment

Continuous flow hydraulic equipment (i..e.., hydraulic motors) should be connected as per the table below depending on the coupler manifold configuration.. The supply hose is connected to the a left coupler and the return hose is connected to the corresponding right coupler..

Manual hydraulics | Connect to row |

|

|

4 to 6 Section | 3 to 6 |

|

|

Connect to row | |

|

|

4 section | 4 |

|

|

6 set (high flow) | 4 or 6 |

|

|

8 set (high flow) | 5 or 8 |

|

|

(1 starting at the bottom)

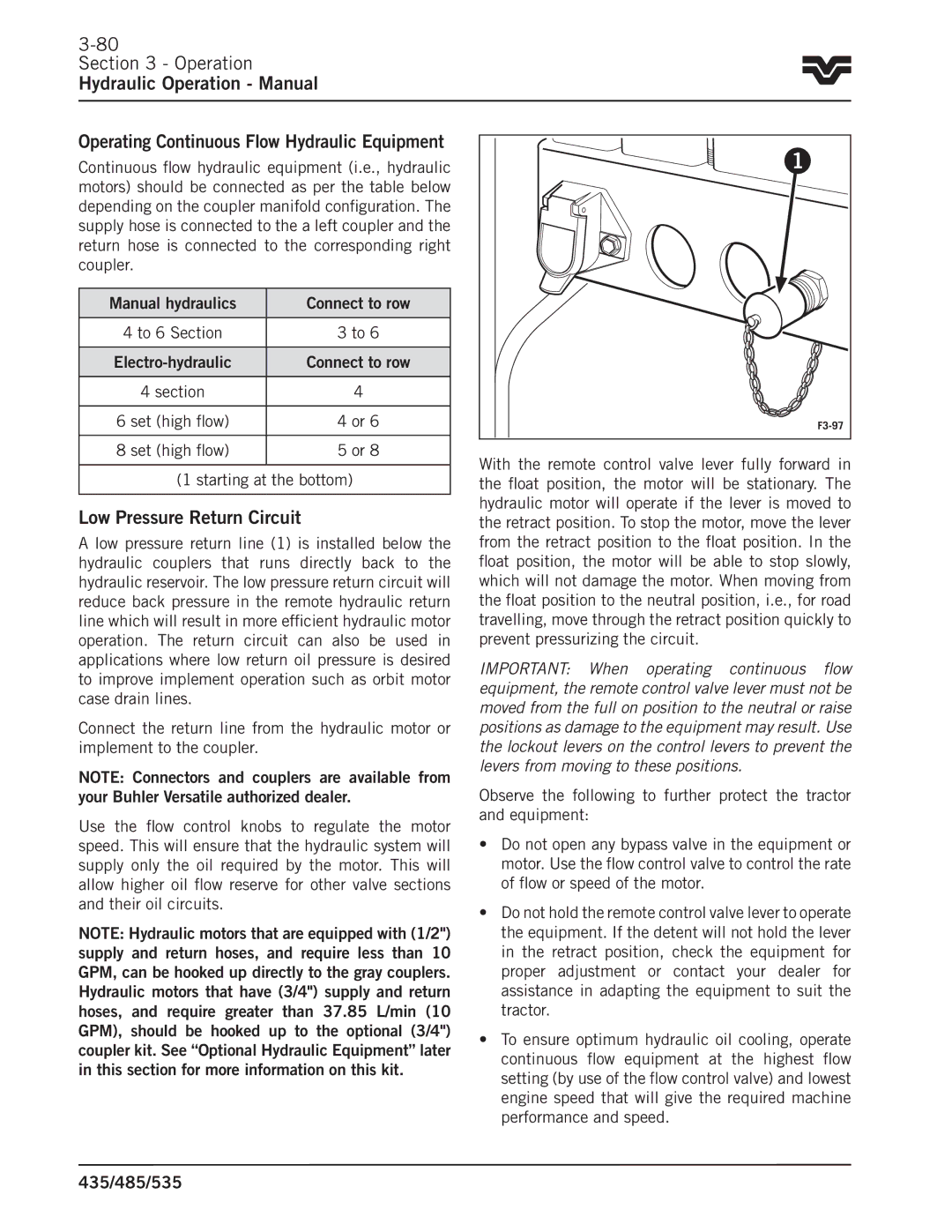

Low Pressure Return Circuit

A low pressure return line (1) is installed below the hydraulic couplers that runs directly back to the hydraulic reservoir.. The low pressure return circuit will reduce back pressure in the remote hydraulic return line which will result in more efficient hydraulic motor operation.. The return circuit can also be used in applications where low return oil pressure is desired to improve implement operation such as orbit motor case drain lines..

Connect the return line from the hydraulic motor or implement to the coupler..

NOTE: Connectors and couplers are available from your Buhler Versatile authorized dealer.

Use the flow control knobs to regulate the motor speed.. This will ensure that the hydraulic system will supply only the oil required by the motor.. This will allow higher oil flow reserve for other valve sections and their oil circuits..

NOTE: Hydraulic motors that are equipped with (1/2") supply and return hoses, and require less than 10 GPM, can be hooked up directly to the gray couplers. Hydraulic motors that have (3/4") supply and return hoses, and require greater than 37.85 L/min (10 GPM), should be hooked up to the optional (3/4") coupler kit. See “Optional Hydraulic Equipment” later in this section for more information on this kit.

1 |

With the remote control valve lever fully forward in the float position, the motor will be stationary.. The hydraulic motor will operate if the lever is moved to the retract position.. To stop the motor, move the lever from the retract position to the float position.. In the float position, the motor will be able to stop slowly, which will not damage the motor.. When moving from the float position to the neutral position, i..e.., for road travelling, move through the retract position quickly to prevent pressurizing the circuit..

IMPORTANT: When operating continuous flow equipment, the remote control valve lever must not be moved from the full on position to the neutral or raise positions as damage to the equipment may result. Use the lockout levers on the control levers to prevent the levers from moving to these positions.

Observe the following to further protect the tractor and equipment:

•Do not open any bypass valve in the equipment or motor.. Use the flow control valve to control the rate of flow or speed of the motor..

•Do not hold the remote control valve lever to operate the equipment.. If the detent will not hold the lever in the retract position, check the equipment for proper adjustment or contact your dealer for assistance in adapting the equipment to suit the tractor..

•To ensure optimum hydraulic oil cooling, operate continuous flow equipment at the highest flow setting (by use of the flow control valve) and lowest engine speed that will give the required machine performance and speed..