Section 4 - Lubrication & Maintenance

Every 1500 Hours or Yearly

Operation 58

Check the Transmission Mounts

Check the rubber transmission mounts and mounting hardware for condition and torque on both the Synchromesh and powershift transmissions..

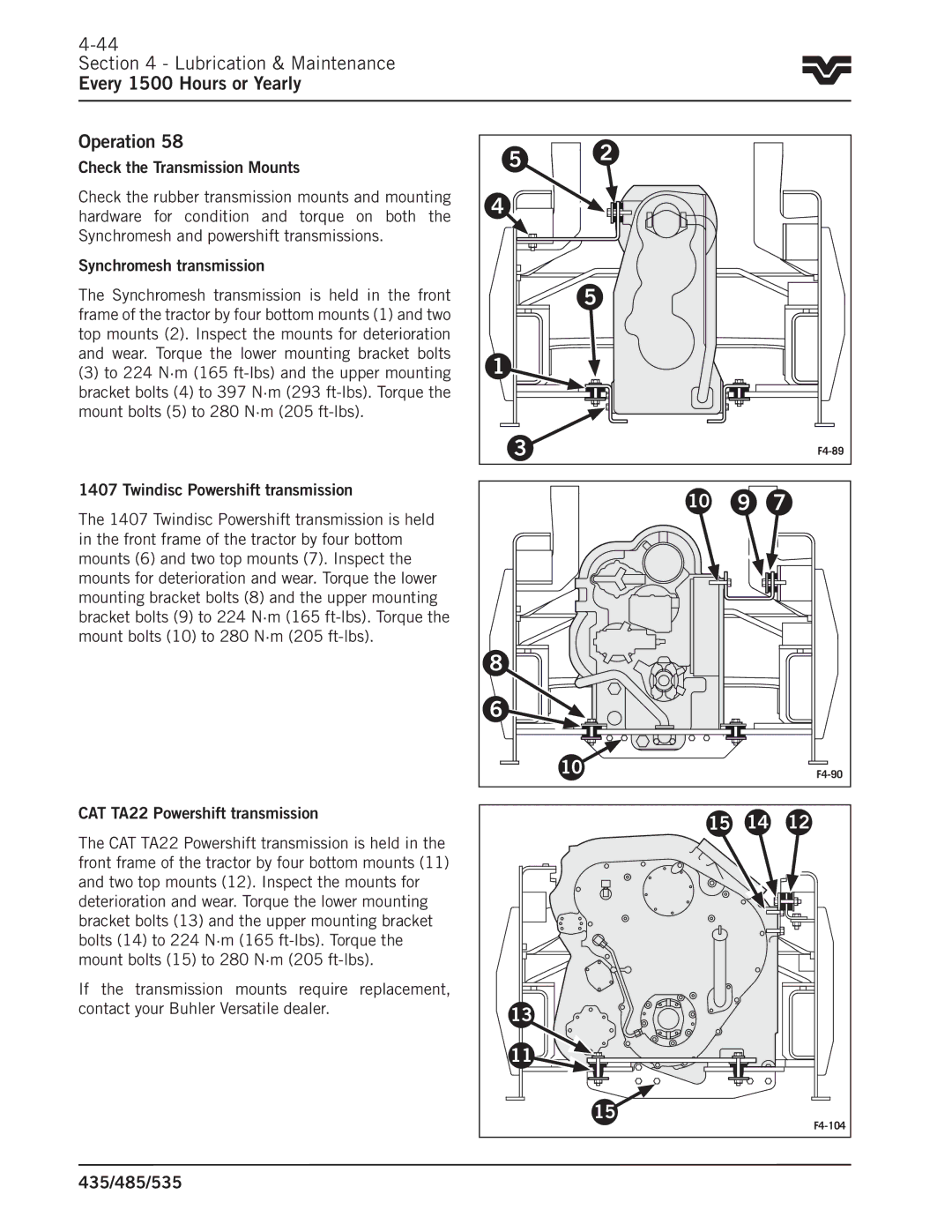

Synchromesh transmission

The Synchromesh transmission is held in the front frame of the tractor by four bottom mounts (1) and two top mounts (2).. Inspect the mounts for deterioration and wear.. Torque the lower mounting bracket bolts

(3)to 224 N..m (165

1407 Twindisc Powershift transmission

The 1407 Twindisc Powershift transmission is held in the front frame of the tractor by four bottom mounts (6) and two top mounts (7).. Inspect the mounts for deterioration and wear.. Torque the lower mounting bracket bolts (8) and the upper mounting bracket bolts (9) to 224 N..m (165

CAT TA22 Powershift transmission

The CAT TA22 Powershift transmission is held in the front frame of the tractor by four bottom mounts (11) and two top mounts (12).. Inspect the mounts for deterioration and wear.. Torque the lower mounting bracket bolts (13) and the upper mounting bracket bolts (14) to 224 N..m (165

If the transmission mounts require replacement, contact your Buhler Versatile dealer..

5 | 2 |

|

|

|

|

| |

4 |

|

|

|

| 5 |

|

|

1 |

|

|

|

3 |

|

| |

|

|

| |

| 10 | 9 | 7 |

8 |

|

|

|

6 |

|

|

|

| 10 |

| |

| 15 | 14 | 12 |

13 |

|

|

|

11 |

|

|

|

| 15 |

| |

|

|

| |

|

|

|