Example:

425, 485 & 535 Unballasted Shipping Weight

Front axle weight: | 9,130 kg (20,130 lbs..) |

Rear axle weight: | 4,821 kg (10,630 lbs..) |

Total tractor |

|

shipping weight: | 13,592 kg (30,758 lbs..) |

Weight distribution |

|

Front axle: | 9,130÷13,952 |

| (20,130÷30,758) = 65% |

Additional Ballast Requirements

Total ballast to be added can now be calculated by subtracting the shipping weight of the tractor, from the recommended operating weight, determined from the chart..

Example:

Recommended Operating Weight:

485 (485 HP) | 22,000 kg (48,500 lbs..) |

Shipping Weight: |

|

485 (485 HP) | 13,952 kg (30..758 lbs..) |

Rear axle: | 4,820÷13,952 |

| (10,628÷30,952) = 35% |

NOTE: The above example is not an exact shipping weight of a tractor. Weigh your specific tractor to get accurate figures to work with.

For optimum performance the tractor requires ballasting to obtained 50% balance of the load being carried on each axle during field work.. This makes each axle pull its share of the load so that one axle is not overworked..

Operating Weight and Fore/Aft Ratio

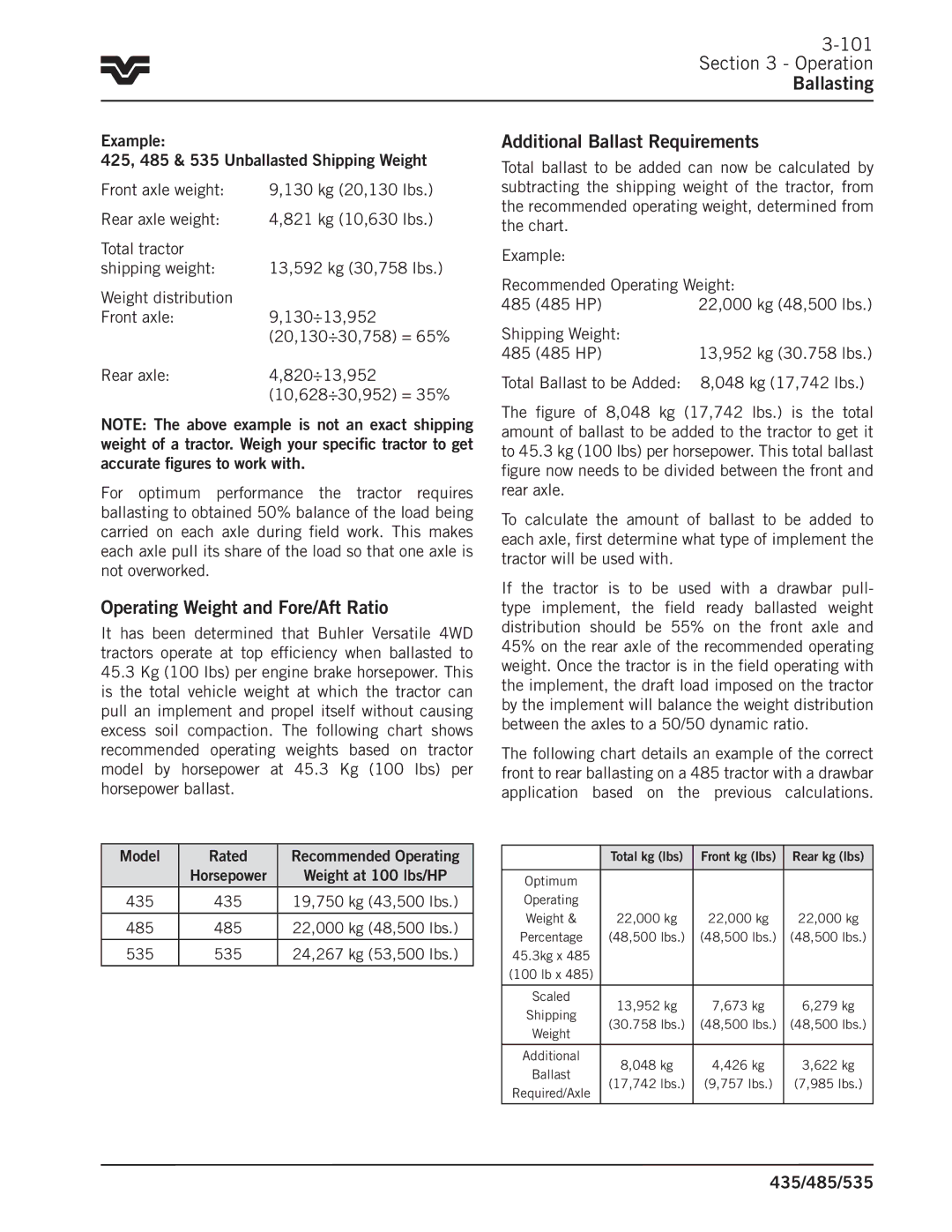

It has been determined that Buhler Versatile 4WD tractors operate at top efficiency when ballasted to 45..3 Kg (100 lbs) per engine brake horsepower.. This is the total vehicle weight at which the tractor can pull an implement and propel itself without causing excess soil compaction.. The following chart shows recommended operating weights based on tractor model by horsepower at 45..3 Kg (100 lbs) per horsepower ballast..

Total Ballast to be Added: 8,048 kg (17,742 lbs..)

The figure of 8,048 kg (17,742 lbs..) is the total amount of ballast to be added to the tractor to get it to 45..3 kg (100 lbs) per horsepower.. This total ballast figure now needs to be divided between the front and rear axle..

To calculate the amount of ballast to be added to each axle, first determine what type of implement the tractor will be used with..

If the tractor is to be used with a drawbar pull- type implement, the field ready ballasted weight distribution should be 55% on the front axle and 45% on the rear axle of the recommended operating weight.. Once the tractor is in the field operating with the implement, the draft load imposed on the tractor by the implement will balance the weight distribution between the axles to a 50/50 dynamic ratio..

The following chart details an example of the correct front to rear ballasting on a 485 tractor with a drawbar application based on the previous calculations..

Model | Rated | Recommended Operating |

| Horsepower | Weight at 100 lbs/HP |

|

|

|

435 | 435 | 19,750 kg (43,500 lbs..) |

|

|

|

485 | 485 | 22,000 kg (48,500 lbs..) |

|

|

|

535 | 535 | 24,267 kg (53,500 lbs..) |

|

|

|

| Total kg (lbs) | Front kg (lbs) | Rear kg (lbs) | |

|

|

|

| |

Optimum |

|

|

| |

Operating |

|

|

| |

Weight & | 22,000 kg | 22,000 kg | 22,000 kg | |

Percentage | (48,500 lbs..) | (48,500 lbs..) | (48,500 lbs..) | |

45..3kg x 485 |

|

|

| |

(100 lb x 485) |

|

|

| |

|

|

|

| |

Scaled | 13,952 kg | 7,673 kg | 6,279 kg | |

Shipping | ||||

(30..758 lbs..) | (48,500 lbs..) | (48,500 lbs..) | ||

Weight | ||||

|

|

| ||

|

|

|

| |

Additional | 8,048 kg | 4,426 kg | 3,622 kg | |

Ballast | ||||

(17,742 lbs..) | (9,757 lbs..) | (7,985 lbs..) | ||

Required/Axle | ||||

|

|

| ||

|

|

|

|