Model 100AH Sulfur Dioxide Analyzer High Level

SAN DIEGO, CA TOLL-FREE FAX TEL Mail api-sales@teledyne.com

Safety Messages

Table of Contents

Optional Hardware and Software

Maintenance

10-1

11 M100AH Spare Parts List

List of Figures

Vii

List of Tables

Viii

Front Panel Warning Messages

Intentionally Blank

HOW to USE this Manual

Intentionally Blank

Installation

Getting Started

Electrical and Pneumatic Connections

Page

Removal of Shipping Screws

Rear Panel

Rear Panel Pneumatic Recommendations

Initial Operation

Step Number Action Comment

RNGE-SET

M100AH is now ready to measure sample gas

Front Panel

Assembly Layout

Final Test and Calibration Values

Test Values Observed Units Nominal Range Reference Section

Electric Test & Optic Test

Optic Test

Measured Flows

Factory Installed Options Option Installed

SO2 Range Spare Test Output

Intentionally Blank

Specifications

SPECIFICATIONS, Agency APPROVALS, Warranty

PPM RMS

Warranty

Warranty Policy 02024c

Terms and Conditions

Intentionally Blank

M100AH SO2 Analyzer

Principle of Operation

M100AH Sulfur Dioxide Analyzer

Instrument Description

Sensor Module, Reaction Cell, Detector

Pneumatic Sensor Board

Computer Hardware and Software

4 V/F Board

Front Panel

Mode Meaning

System Modes Display

Front Panel Display

Status LEDs

Power Supply Module

Power Switch

Pneumatic System

Front Panel Status LEDs

I/O Hardware Interface

1 RS-232 Interface

RS-232 Pin Assignments

1.2 RS-232 Diagnostic Procedures

1.1 RS-232 Connection Examples

Status Output Interface

Status Output Pin Assignments

Output #

Definition Condition

Interfacing Contact Closure I/O

Contact Closure Control Input Interface

Intentionally Blank

Software Features

Index To Front Panel Menus

Sample Menu

Sample Menu

M100AH Sample Menu Structure

M100AH Setup Menu Structure

Set-Up Menu

M100AH Menu Structure Setup Menu #2

Setup Menu #2 Level Description Reference Section

M100AH Menu Structure Setup Menu #3

Setup Menu #3 Level Description Reference Section

Sample Mode

Test Functions

Sample Flow

Time

2 CAL, CALS, CALZ, Calibration Functions

2.1 CAL, CALS, Calz

Zero

Span

2.4 SO2 Cal Concentration

Formula Values

Set-Up Mode

Configuration Information CFG

Automatic Calibration AutoCal

Data Acquisition System DAS

Page

3.2 RS-232 Reporting

Step Action Comment Press SETUP-DAS

Press PREV/NEXT

Range Menu

Single Range

Auto Range

Dual Ranges

Concentration Units

Password Enable

Diagnostic Mode

Calibrate, Setup Passwords

Time of Day Clock

Variables Menu Vars

Intentionally Blank

Mode Description Reference Section

Optional Hardware and Software

Rack Mount Options

Zero/Span Valves

Autocal Setup Zero/Span Valves

Setup Automatic Zero/Span Calibration

Default Description

Mmddyy

OFF

Mode ZERO-HI Timer Enable on

Mode Zero Timer Enable on

4-20 mA, Isolated Current Loop Output

Setup from the Front Panel

Setting Up the RS-232 Interface

RS-232 Interface

RS-232 Port Setup Front Panel

Security Feature

Decimal Value Description

Protocol of Port Communication

RS-232 Switching From Terminal Mode to Computer Mode

Key Function

Entering Commands in Terminal Mode

RS-232 Terminal Mode Editing Keys

RS-232 Interface Command Types

Command Summary

First Character Message Type

RS-232 Command Summary

Commands Definition

Computer Mode Editing Keys Definition

Terminal Mode Editing Keys Definition

Security Features Definition

RS-232 Test Messages

Test Commands and Messages

Name Message Description

RS-232 Warning Messages

Clear ALL

RS-232 Calibration Messages

Calibration Commands and Messages

Message Description

10 RS-232 Calibration Commands

Command Description

Diagnostic Commands and Messages

11 RS-232 Diagnostic Command Summary

DAS Commands and Reports

12 RS-232 DAS Commands

RS-232 DAS Commands

Compactverbose

Data Report Format

Mode Description

Variables Commands and Messages

13 RS-232 Operating Modes

Config 2 = SBC40 CPU

Intentionally Blank

Types of Zero/Span Checks and Calibrations

Calibration and ZERO/SPAN Checks

Section Type of Cal or Check Description

Model 100AH Calibration Setup

Entr

Enter Expected Span Gas Concentration Procedure

CAL-CONC

Manual Zero Calibration Procedure Z/S Valves

Manual Span Calibration Procedure Z/S Valves

Dynamic Zero/Span Calibration

Automatic Zero/Span Check

Use of Zero/Span Valves with Remote Contact Closure

Z/S Valves Mode with Remote Contact Closure

Ext Zero CC Ext Low Span CC Ext High Span CC Operation

Calibration Quality Check

Calibration Quality

Step Action Comment

Calibration Gases

Intentionally Blank

Maintenance

Maintenance Schedule

Preventative Maintenance Schedule

Maintenance Interval Reference Section

Replacing the Sample Particulate Filter

Replacing the Particulate Filter

Cleaning Orifice and Orifice Filter

Replacing the Pump Scrubber

Cleaning the Reaction Cell

Pneumatic Line Inspection

Reaction Cell

Pneumatic Diagram

Leak Check Procedure

Light Leak Check Procedure

Eprom Replacement Procedure

DIAGNOSTIC, Troubleshooting

10-1

10-2

Operation Verification M100AH Diagnostic Techniques

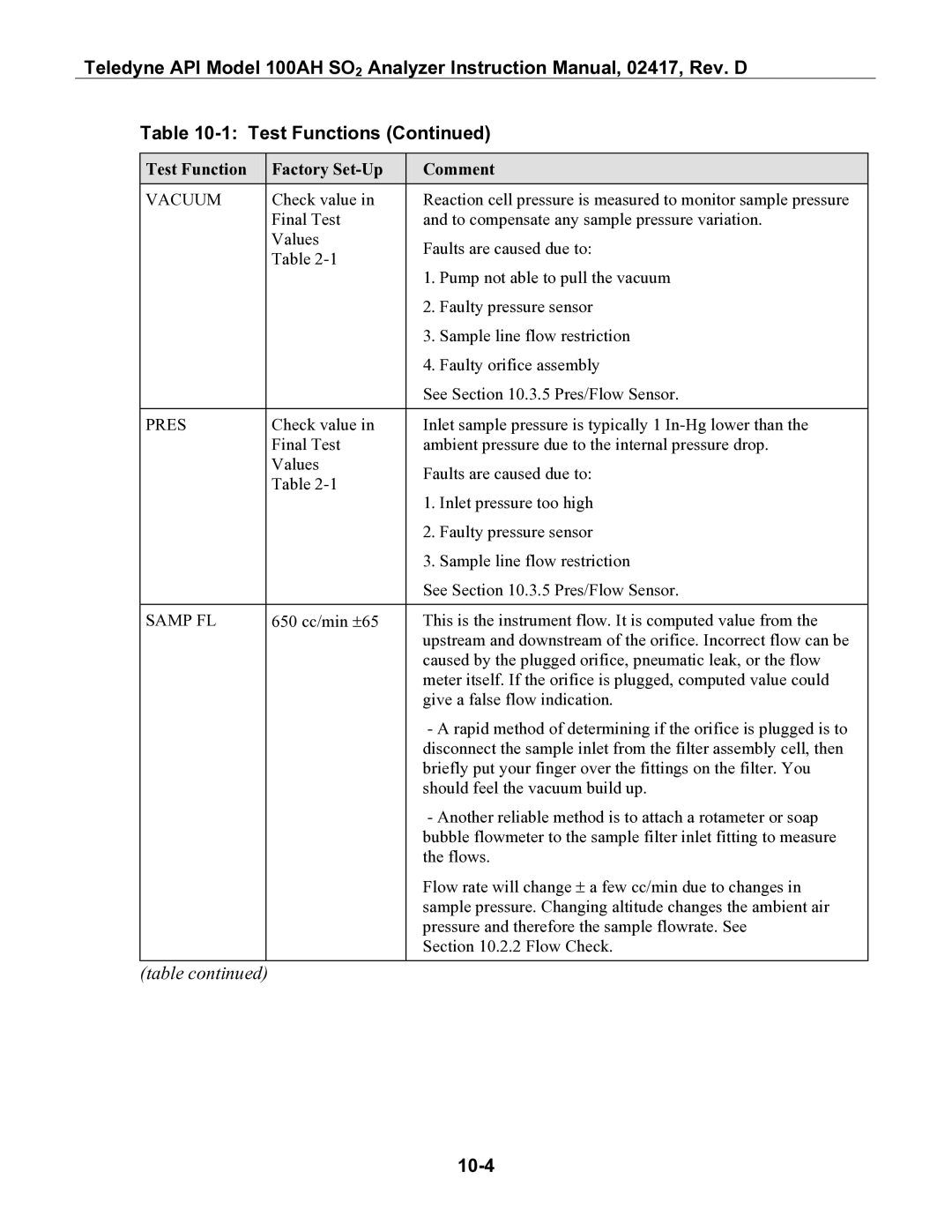

Fault Diagnosis with Test Variables

Test Functions

10-3

Pres

10-4

Samp FL

10-5

10-6

Lamp Ratio

STR LGT

DRK PMT

10-7

DRK LMP

10-8

Time

Fault Diagnosis with Warning Messages

Front Panel Warning Messages

10-9

Sample Flow

10-10

Fault Diagnosis using Diagnostic Mode

10-11

Diag Mode Description

Summary of Diagnostic Modes

10-12

Signal

10.1.3.1 Signal I/O Diagnostic Diagnostic Mode Signal I/O

10-13

Signal Control Description

10-14

10-15

Electric Test

10-16

Analog Out Step Test

Optic Test

10-17

10.1.4 M100AH Internal Variables

DAC Calibration

10.1.3.6 RS-232 Port Test

10-18

Model 100AH Variables

Name Units Default Value Description Range

10-19

Test Channel Analog Output

Test Channel Output

10-20

Name Description Scaled Range

Factory Calibration Procedure Quick Cal

10-21

Optic Test OT Procedure

Electric Test ET Procedure

10-22

AC Power Check

Performance Problems

10-23

No Response to Sample Gas

Flow Check

10-24

Excessive Noise

Negative Concentration Display

10-25

Unstable Zero

Unstable Span

10-26

Inability to Zero

Inability to Span

10-27

Non-Linear Response

Slow Response

Analog Output Doesnt Agree with Display Concentration

10-28

Computer, Display, Keyboard

Electronic Subsystem Troubleshooting and Adjustments

10-29

Single Board Computer

10-30

CPU Board Jumper Settings 10-31

Front Panel Keyboard

10-32

Voltage/Frequency V/F Board

10-33

10-34

10.3.2.1 ADC/DAC Calibration Procedure

10-35

Changing Output Voltage Ranges

10-36

V/F Board Dip Switch Settings 10-37

Status/Temp Board

Temperature Amplifier Section

10-38

Status Output Lines, External Contact Closures

Display Brownout

10-39

10.3.3.4 4-20 mA Current Output

10-40

10-41

Power Supply Module Subassemblies

Module Description

Power Supply Module Layout 10-42

Electrical Block Diagram 10-43

PSM Diagnostic Procedures

Power Supply Module LED Operation

10-44

Function Description

Flow/Pressure Sensor

10-45

Pressure/Flow Sensor 10-46

SO2 Sensor Module 10-47

SO2 Sensor Module 10-48

Preamp Board

Reaction Cell Temp

10-49

PMT Cooler

10-50

PMT Cooler Subsystem 10-51

Hvps High Voltage Power Supply

10-52

High Voltage Power Supply 10-53

Optical Sensor Module Troubleshooting

UV Lamp Adjust or Replacement

10.4.1 PMT

10-54

To adjust the beam splitter assembly

10-55

Pneumatic System Troubleshooting

Leak Check

Pump

10.5.3 Z/S Valves

Teledyne API M100AH Spare Parts List

11 M100AH Spare Parts List

11-1

11-2

Model 100AH Level 1 Spares Kit

Teledyne API M100AH Level 1 Spares Kit

Teledyne API M100AH 47 mm Expendables Kit

11-3

11-4

Particulate Replace Weekly AS Needed Filter Element

Appendix a Maintenance Schedule for M100AH

Replace Quarterly

Intentionally Blank

Appendix B Electrical Schematics

Part Number Name

Intentionally Blank