Rosemount 8732

Reference Manual

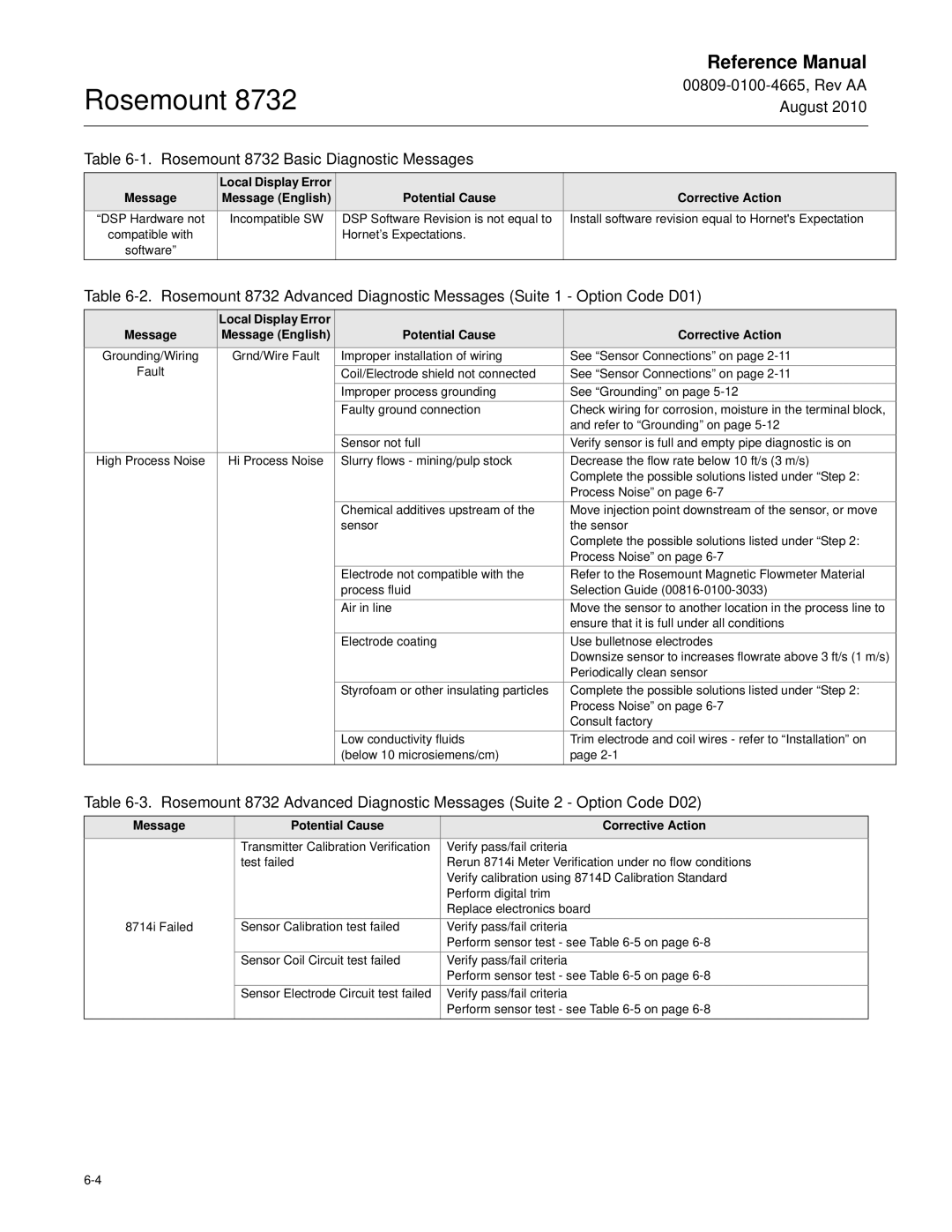

Table

Message | Local Display Error | Potential Cause | Corrective Action |

Message (English) | |||

“DSP Hardware not | Incompatible SW | DSP Software Revision is not equal to | Install software revision equal to Hornet's Expectation |

compatible with |

| Hornet’s Expectations. |

|

software” |

|

|

|

Table

| Local Display Error |

|

|

Message | Message (English) | Potential Cause | Corrective Action |

Grounding/Wiring | Grnd/Wire Fault | Improper installation of wiring | See “Sensor Connections” on page |

Fault |

| Coil/Electrode shield not connected | See “Sensor Connections” on page |

|

| Improper process grounding | See “Grounding” on page |

|

| Faulty ground connection | Check wiring for corrosion, moisture in the terminal block, |

|

|

| and refer to “Grounding” on page |

|

| Sensor not full | Verify sensor is full and empty pipe diagnostic is on |

High Process Noise | Hi Process Noise | Slurry flows - mining/pulp stock | Decrease the flow rate below 10 ft/s (3 m/s) |

|

|

| Complete the possible solutions listed under “Step 2: |

|

|

| Process Noise” on page |

|

| Chemical additives upstream of the | Move injection point downstream of the sensor, or move |

|

| sensor | the sensor |

|

|

| Complete the possible solutions listed under “Step 2: |

|

|

| Process Noise” on page |

|

| Electrode not compatible with the | Refer to the Rosemount Magnetic Flowmeter Material |

|

| process fluid | Selection Guide |

|

| Air in line | Move the sensor to another location in the process line to |

|

|

| ensure that it is full under all conditions |

|

| Electrode coating | Use bulletnose electrodes |

|

|

| Downsize sensor to increases flowrate above 3 ft/s (1 m/s) |

|

|

| Periodically clean sensor |

|

| Styrofoam or other insulating particles | Complete the possible solutions listed under “Step 2: |

|

|

| Process Noise” on page |

|

|

| Consult factory |

|

| Low conductivity fluids | Trim electrode and coil wires - refer to “Installation” on |

|

| (below 10 microsiemens/cm) | page |

Table

Message | Potential Cause | Corrective Action |

| Transmitter Calibration Verification | Verify pass/fail criteria |

| test failed | Rerun 8714i Meter Verification under no flow conditions |

|

| Verify calibration using 8714D Calibration Standard |

|

| Perform digital trim |

|

| Replace electronics board |

8714i Failed | Sensor Calibration test failed | Verify pass/fail criteria |

|

| Perform sensor test - see Table |

| Sensor Coil Circuit test failed | Verify pass/fail criteria |

|

| Perform sensor test - see Table |

| Sensor Electrode Circuit test failed | Verify pass/fail criteria |

|

| Perform sensor test - see Table |