Reference Manual

Rosemount 8732

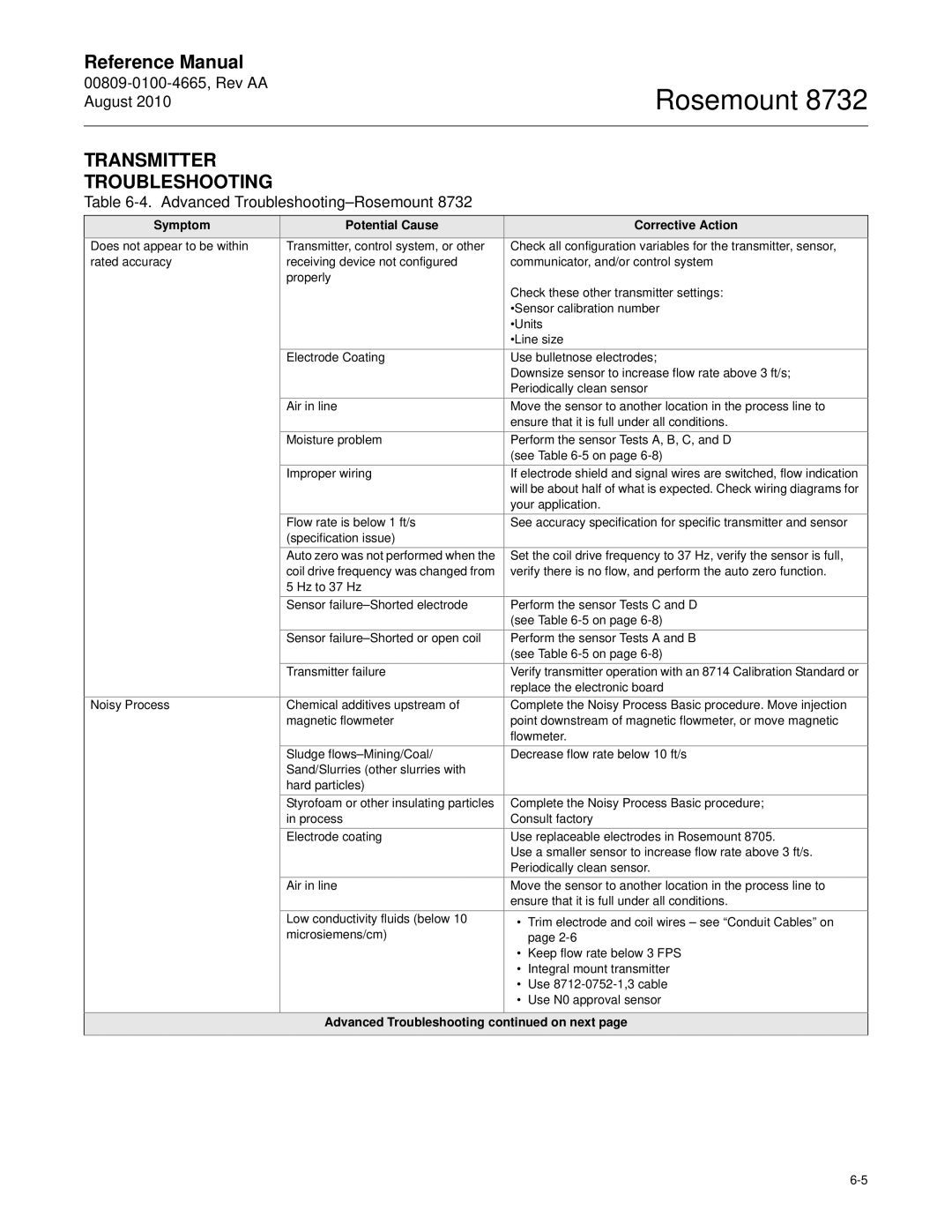

TRANSMITTER

TROUBLESHOOTING

Table 6-4. Advanced Troubleshooting–Rosemount 8732

Symptom | Potential Cause |

| Corrective Action |

Does not appear to be within | Transmitter, control system, or other | Check all configuration variables for the transmitter, sensor, | |

rated accuracy | receiving device not configured | communicator, and/or control system | |

| properly | Check these other transmitter settings: | |

|

| ||

|

| •Sensor calibration number | |

|

| •Units | |

|

| •Line size | |

| Electrode Coating | Use bulletnose electrodes; | |

|

| Downsize sensor to increase flow rate above 3 ft/s; | |

|

| Periodically clean sensor | |

| Air in line | Move the sensor to another location in the process line to | |

|

| ensure that it is full under all conditions. | |

| Moisture problem | Perform the sensor Tests A, B, C, and D | |

|

| (see Table | |

| Improper wiring | If electrode shield and signal wires are switched, flow indication | |

|

| will be about half of what is expected. Check wiring diagrams for | |

|

| your application. | |

| Flow rate is below 1 ft/s | See accuracy specification for specific transmitter and sensor | |

| (specification issue) |

|

|

| Auto zero was not performed when the | Set the coil drive frequency to 37 Hz, verify the sensor is full, | |

| coil drive frequency was changed from | verify there is no flow, and perform the auto zero function. | |

| 5 Hz to 37 Hz |

|

|

| Sensor | Perform the sensor Tests C and D | |

|

| (see Table | |

| Sensor | Perform the sensor Tests A and B | |

|

| (see Table | |

| Transmitter failure | Verify transmitter operation with an 8714 Calibration Standard or | |

|

| replace the electronic board | |

Noisy Process | Chemical additives upstream of | Complete the Noisy Process Basic procedure. Move injection | |

| magnetic flowmeter | point downstream of magnetic flowmeter, or move magnetic | |

|

| flowmeter. | |

| Sludge | Decrease flow rate below 10 ft/s | |

| Sand/Slurries (other slurries with |

|

|

| hard particles) |

|

|

| Styrofoam or other insulating particles | Complete the Noisy Process Basic procedure; | |

| in process | Consult factory | |

| Electrode coating | Use replaceable electrodes in Rosemount 8705. | |

|

| Use a smaller sensor to increase flow rate above 3 ft/s. | |

|

| Periodically clean sensor. | |

| Air in line | Move the sensor to another location in the process line to | |

|

| ensure that it is full under all conditions. | |

| Low conductivity fluids (below 10 | • | Trim electrode and coil wires – see “Conduit Cables” on |

| microsiemens/cm) |

| page |

|

| • Keep flow rate below 3 FPS | |

|

| • | Integral mount transmitter |

|

| • | Use |

|

| • Use N0 approval sensor | |

| Advanced Troubleshooting continued on next page | ||

|

|

|

|