Rosemount 8732

Reference Manual

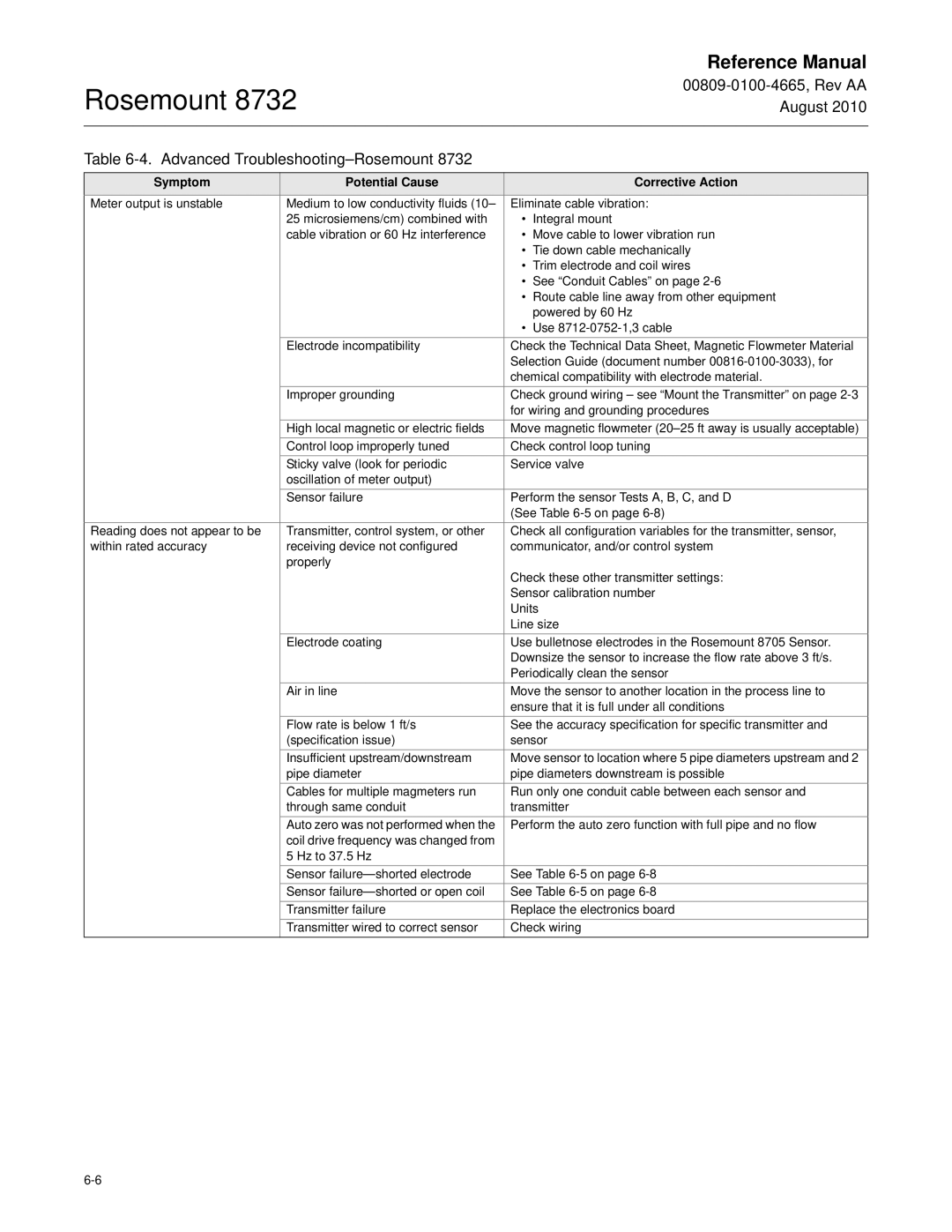

Table 6-4. Advanced Troubleshooting–Rosemount 8732

Symptom | Potential Cause |

| Corrective Action |

Meter output is unstable | Medium to low conductivity fluids (10– | Eliminate cable vibration: | |

| 25 microsiemens/cm) combined with | • | Integral mount |

| cable vibration or 60 Hz interference | • | Move cable to lower vibration run |

|

| • | Tie down cable mechanically |

|

| • | Trim electrode and coil wires |

|

| • See “Conduit Cables” on page | |

|

| • | Route cable line away from other equipment |

|

|

| powered by 60 Hz |

|

| • | Use |

| Electrode incompatibility | Check the Technical Data Sheet, Magnetic Flowmeter Material | |

|

| Selection Guide (document number | |

|

| chemical compatibility with electrode material. | |

| Improper grounding | Check ground wiring – see “Mount the Transmitter” on page | |

|

| for wiring and grounding procedures | |

| High local magnetic or electric fields | Move magnetic flowmeter | |

| Control loop improperly tuned | Check control loop tuning | |

| Sticky valve (look for periodic | Service valve | |

| oscillation of meter output) |

|

|

| Sensor failure | Perform the sensor Tests A, B, C, and D | |

|

| (See Table | |

Reading does not appear to be | Transmitter, control system, or other | Check all configuration variables for the transmitter, sensor, | |

within rated accuracy | receiving device not configured | communicator, and/or control system | |

| properly | Check these other transmitter settings: | |

|

| ||

|

| Sensor calibration number | |

|

| Units | |

|

| Line size | |

| Electrode coating | Use bulletnose electrodes in the Rosemount 8705 Sensor. | |

|

| Downsize the sensor to increase the flow rate above 3 ft/s. | |

|

| Periodically clean the sensor | |

| Air in line | Move the sensor to another location in the process line to | |

|

| ensure that it is full under all conditions | |

| Flow rate is below 1 ft/s | See the accuracy specification for specific transmitter and | |

| (specification issue) | sensor | |

| Insufficient upstream/downstream | Move sensor to location where 5 pipe diameters upstream and 2 | |

| pipe diameter | pipe diameters downstream is possible | |

| Cables for multiple magmeters run | Run only one conduit cable between each sensor and | |

| through same conduit | transmitter | |

| Auto zero was not performed when the | Perform the auto zero function with full pipe and no flow | |

| coil drive frequency was changed from |

|

|

| 5 Hz to 37.5 Hz |

|

|

| Sensor | See Table | |

| Sensor | See Table | |

| Transmitter failure | Replace the electronics board | |

| Transmitter wired to correct sensor | Check wiring | |