InterForm400

User’s Manual for InterForm400

User’s Manual for InterForm400

Table of Contents

126

116

122

General Description of Auto Forms Control Sub-system 132

136

Work with Active Subsystem Autoform 133

134

155

181

Split Definitions 173

221

238

Administering InterForm400 Environment and Users 266

230

241

292

278

292

298

325

319

323

329

378

Appendix B Attaching Printers to the iSeries

374

380

430

426

435

477

459

461

480

About This Manual

How the manual is organized

Trouble Shooting L

Important information

User’s Manual for InterForm400

What is new in the 2006 version

What is new in this manual

InterForm400 Classic package

Modules of InterForm400

Basic InterForm400 package

ZPL Module

InterWord400 Module

InterFax400 Module

Getting Started

Installation

Preparation

InterForm 400 version 2004.M01

INS0121

Press F10 to complete the installation

APF101D

Setting Up the System

Enter 2. Configure InterForm

ZEBRA203 ZEBRA300

= Letter

= Legal = Monarch = Executive

=*EXCLUDE

APF101D

Printer Writer Twinax, or TCP/IP TN5250E or Raw Socket

Work With Overlay/AFC Sample

Remote Writer TCP/IP LPD

Trouble Shooting L

About The Print Results

Work with the Getting familiar with overlays section

User’s Manual for InterForm400

Menu Structures and General Operation

You will then be presented with the InterForm400 main menu

User’s Manual for InterForm400

Selecting an existing overlay

Design Overlay

Creating a new overlay

F9=Copy from another file set

Copy Overlay from Another Overlay

F10=Copy from another AS/400

Extra Left

Global settings of an overlay

Extra blank

255

Extended Def

Drawer

Paper Size

Duplex

Duplex options

Copy

Forced front

Prefix

Function keys for display of a spool file

F13 Set view/print parameters

Secondary Set

Overlay Name

Primary

Overlay Selector

Copies Drawer

Code

Form type

View

Especially Zebra related parameters are

Considerations for Zebra overlays

Label length/width

TIP J

Extended Page Definition

Copy Management

Stapling

Source Drawers for Copies

F18=DSPSPLF F19=DSPPFM

Measuring Methods

Orientation of design elements

Design Screen

Move definitions to another sequence number

Service Options

Move the placement on

Copy definitions into this overlay

Resequencing

Delete lines

Print overlay definitions

Overlay Element Selection Filters

Control

Copy Management

Use this overlay element on all copies of the Primary set

Overlay elements

F4=List

Color

Inch.pel Repetition Horizontal line

Lower end

From Top Edge

From left

Thickness Pels

HPGL/2 compatible printer

Global settings for the overlay From left

Rotation

Text

=Print-info Print information

Value Prints out

=INK fill pattern for succeeding sequence lines

Examples on use of Ink

See above

Black Ink Slash / Ink Ink followed 0 Ink By Ink/ / Ink

Color

Input Line

=TABULATOR Paragraph tabulation

Window

Input Position

Punctuation

Adjustment

Underline

Condition

100,00

=REMAP Window re-mapping text areas

Mickey Mouse 1.100,00 refund Ears -2.100,00 Total 1.000,00

Refund Ears 100,00 Total 000,00

Ignore Blank Lines

Upper edge

From left edge

Left

Escape

Adjustement

Right margin

Blank original

Image imported under 8. Work with Images

Administration menu. Refer to page 319 for details

Image name

Reverse Image

?=IF...THEN conditional nesting of overlays

Lines to remap

Overlay

Number

Vertical cursor repositioning

Position related to actual position

Reposition related to previous non blank input line

=PCL-FILE

PCL file is added to this value. Adding a minus after

Inches, pels vertical position of the HP-GL/2 file is made

½ negative movement

Value, will cause a movement to the left. e.g ,120- for

=SUBOVERLAY

0003 Recepient Frame

0001

Demoimage

0005

How the sequence lines in overlay design are executed

If..Then

User’s Manual for InterForm400

Chapter requires you have

Getting Familiar With Overlays

It is recommend that you have

Sample

Making a Work Copy of the Overlay IF400DEMO

F9=Copy from another overlay

Now we select overlay IF400DEMO and press Enter

Copy from another overlay

We select file-set Sample and press Enter

InterForm 400 Samples

Enter menu 3. Merge spool entry with overlay

Make a Test Print of the Overlay+Spool Data

NO, *YES

Peter

We select the file with option 1 and press Enter

DSP010700

073534

Entering the Design Window

Adding Round Corners to the Address Field

Printing the Overlay Definition List

Print out a list of the definitions by pressing F5

Having to leave the design window

Edit Subject Text

Merge spool entry with overlay

END

File

Qprint

Re. Your new MateSert/400 driver

06-011 pos

Formatting the body text

10,0

Making Equal Distance Between Column Headers

000004

13,0

28 28 Position 26

14,0

Making Equal Distance between Item Line Columns

We press F5 and we select option 1. Move the placement on

Defining the Column Headers White on Black

11,1

Black

Defining the Item Line Bars

17,1 7 Ink

NW NE SW SE

Defining the 5 Item Coloumn Frames

We measure the bottom edge to be around 7½ 7,120

Defining the logo as a water mark

150

Top 01,100 Left 04,180 0002 Image

Defining the Copy Management

IF400DEMO

Defining the Copy Symbol as Watermark

120

We now proceed by entering type 5 for Text

7001

Defining the Relatively Positioned Sub-form

Light

Intermate A/S

Position Is = N

30,0 ?

060

Cleaning the Overlay for Remaining Text

Result

User’s Manual for InterForm400

Example of Advanced use of Sub-overlays Random text lines

Creating the Main overlay

Creating the sub-overlay for formatting item groups

Search for the footer

1653

1351

040

080

Position 1

Creating the sub-overlay for formatting the footer

Result

User’s Manual for InterForm400

User’s Manual for InterForm400

Test Print Overlay

Main Menu Local Environment Setup

Drawer Overwrite the global drawer settings of the overlay

Copies

Merge Spool Entry with Overlay

APF730D

Print mode

Media type

=Cut requires hardware cutter normally cuts the media for

Select File set

Hardware

Out each label

Hpiii Hpiiid Hpiiip HP4 HP4D HP4PJL

Select Output Queue and Printer Type

Work with actual Output Queue

System SYSTEM850 SYSTEM852 ASCIIR8

APF3812/APFWRKOUTQ

Working with Overlay Selectors

Press F6 to create a new Overlay Selector

Selection Criteria Entries

Interma

Oper

Print Line

Compare Value

User’s Manual for InterForm400

Placing overlays in One File set

Getting Familiar with Overlay Selectors

IF400DEMO

F9 = copy from another file-set F12=Cancel

Examining Spool Entry Selection Criteria

Page/Line 1/15

Enter

Entering the Selection Criterias in the Selector

AA BB

Myselect

Testing the Selector

Job description

General Description of Auto Forms Control Sub- system

User profile

Menu appears like this

End Autoform subsystem

This menu item is a shortcut to the command

Start Autoform subsystem

Work with Active Subsystem Autoform

Hold Spooled File

Overview of AFC Main Definitions

AFC305D

Demo

User’s Manual for InterForm400

AFC300D

Auto Forms Control Definitions

Entering queue and job names to an AFC definition

AFC302D

Auto Start

Default Output Output Queue and Printer Type

Job name

Printer Type

AFC Definition Entries

Additional parameters

Library APF3812 Seqnbr Funct Form type

Merge overprint

=Merge with Overlay

Find overlay

PRI PRI, *SEC

Each label

Output spooled

Save output

=Send Network Spooled File

Hold output

Archive

=Transform Afpds to *USERASCII

Address Refer to the above

=Copy Spooled File

=Move Spooled File

=Call Program

=Hold Spooled File

=Delete Spooled File

File name Char File number

Example

=Exit

=Change attributes

User data

Indicate that a spool entry has been processed

=Split spooled file

= Prepare for Finishing

Finishing Definition

Sort Definition

=Sort Spooled File

NameThe Sort definition name

=Change Writer

=Archive in InfoStore/400

=Archive to MultiArchive/400

For archiving both PCL and *SCS spooled files see

Convert SAP spool entries datatype *IBMSCS

= Comment

PRI

SAP spool entries datatype *IBMSCS2

Generating multiple copies in input spool entries

User’s Manual for InterForm400

Checking the Writer

Example 1, Using Separate queues for Input and Output

Getting Familiar with Auto Forms Control

Checking if Auto Forms Control is running

Autoform Qsys SBS

Entering Auto Forms Definition AFCINPUT1

AFCINPUT1 Afcoper BCH PGM-AFC700

Defining move of print jobs with type *STD

Defining move of Print jobs with Formtype Demo

DEFAULT, *USER

APF3812

Testing new functions in AFCINPUT1

AFCINPUT2 DEFAULT, *USER

Example 2, Using same Queue for Input and Output

AFCOUT2

Creating the AFC Definition

AFCINPUT2

ASCII850

Preventing following AFC functions to process type *STD

Restricting the writer to process type *STD jobs only

Outq

Default

Defining the Overlay Merge

PRI

Cleaning up processed jobs

We press Enter to save this AFC definition

Testing the new AFC definition AFCINPUT2

Activating the AFC job AFCINPUT1

Using a Template AFC defintion

Template

Merged

Input

NONE, *DEFAULT, Nummer

Overlay selection entry field

Form Type Table

AFC310D

User’s Manual for InterForm400

User’s Manual for InterForm400

Press F6 to create a new split definition

Split Definitions

Split Definition Entries

Shipping

Description of the pages selected by this detail line

Split detail Description

Compare with

Calling a User Exit Program with the extracted spool pages

SPL310D

INPUT, *USER, *JOBNAME

INPUT, *NO, *YES

Example Using Split

Ifletter

21 29 EQ InterMate

Iflet

Split, definition Ifletter

Iflet

Finishing Definitions

Testdef

PRS310D

Defining Print Order of Sorted Groups

Our first Prinserter definition

Example 1, Non sorted

Example 2, Sorting in Ascending Weight

Pages per envelope

Example 3 , Sorting in Franking groups

Defining PFE MailPrinter Pre-process Definition

PRI *SEC

YES NO, *YES

Example 1, Non sorted

Example 3 , Sorting in Franking groups

Defining Stapling Pre-process Definitions

= IBM

Defining Insertion Pre-process Definitions

03 = Böwe OMR

Pages in reverse

Placement of optical marks

Print Sequence

Order The output order of the entire print job is reversed

Can there be code for outsorting in the printout

What to do if more than max. pages to a recipient

If YES to the above

How to distribute E-mails and faxes in InterForm400

E-mail/Fax Finishing Definition

By key

How to find E-mail address / Fax number

Find in spooled file

Key definitions

MAI310D

Definition E-mail text / Cover page text

Definition variables

MAI305D

Definition recipient-ID

PRS330D

Mail addresses and fax numbers

Press F6-Create to add a new E-mail address or fax number

=Use fixed sender

Senders E-mail address

MAI350D

Here is the explanations of the fields to fill

Encryption and Signature

=Use owner of spooled file as sender

MAI380D

Personal Certificate

User access limitations

Organisation

Work with E-mail senders

Receipient Key Definition

File Naming Finishing Definition

Variable Definitions

Auto numerator

Spooled print info

Spoolfile attribute

Number of digits to use

Library, *LIBL

Name, *NONE

Parm 1 KEY1-3, *VA-9

Selections and Document breaks

KEY1

Closing User-Exit

Receipient ID Information

PNM365D

Encryption and Signature

We enter 1 for the first Finishing Recipient-ID definition

Define Level Break Conditions for Finishing

Selection Criteria

Character string case sensitive or numeric value which

Example 1, Level Break on Page Counter

Operators used are standard Query operators

Qprint Display Spooled File

Find Recipient ID in the Following Positions

Example 2, Level Break on Change in Customer Info

Example 3, Level Break on Customer ID and Attention Person

Att Martin Merman

PFEDEF1

Using the Finishing Definition with Auto Forms Control

Activate the Finishing pre-process definition

Pfeready

Merge with pre-processed Finishing spool entry

Finishing

Distribute E-mails with Auto Forms Control

Save email

TIP J

Below each of the elements are described

Reformat finishing definition

Head

RFM300D

Definition name Demorefor

Detail lines

User exit program

Select this option and you will get to the screen below

Maximum number of blank

1st page per level break

Following pages

Lines between 2 detail lines

Occurrence

Length

Compare type

Number of lines to Handle

Totals

= Text constant

Just after the last detail line

Foot

If only 1 total

Footer

Insert reformatting in production

If 2 total pages, first total

User’s Manual for InterForm400

Sort Definitions

Insert Pages before

Insert separator page if break

Boolean operator relating to the compare value

Selection criteria

Find sort fields in the following positions

Values. This means that e.g. the which has Ebcdic value

Examples Using Sort

Example 1. Sort by Type, InterMate400 letters first

Example 2. Sort by Type, MateSert/400 letters first

Example 3. Sort by Type and Customer ID

Example 4. Sort by Customer ID and type

Sort, def Sortdemo outq *DEFAULT &form type Sortdone

Seperator

1001 InterFor

Finreport

When you press Enter/F3/F12 you will see this screen

BMK310D

BOOKMRK1

BMK330D

User’s Manual for InterForm400

Demospool

Level-1 Field Prefix Print line Position

Filnvnqprint SPLNBR*LAST Bmkdefdemospool OUTTYPE*VIEW

AFC315D

User Output Queue

KSE HP5SI Qusrsys PDC PRT01

User’s Manual for InterForm400

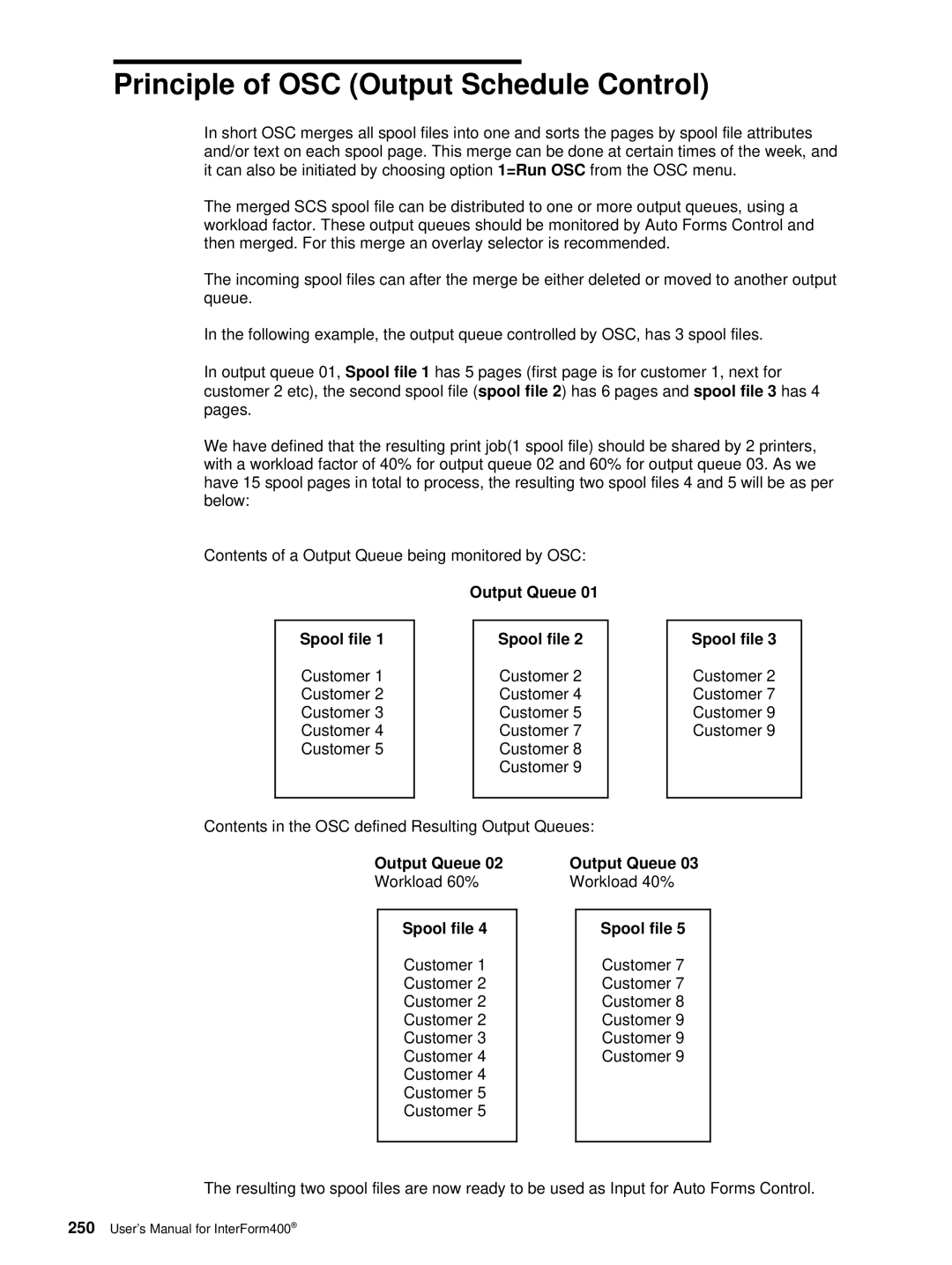

General Description of OSC Output Schedule Control

Work with Active Subsystem Oscctl

Start Oscctl subsystem

End Oscctl subsystem

If the subsystem is started, it will look like this

Describing the OSC definition lines

Define sort fields

Specify placement of input spool file attributes at output

Specify input spooled file priority

Specify grouping and separator

Spool file

Principle of OSC Output Schedule Control

Output Queue Spool file

User’s Manual for InterForm400

OSC100D

Getting Familiar with OSC Output Schedule Control

OSCOUTQ01

Specify placement of input spool file attributes at output

Specify input spooled file priority

OSC335D

Define Sort Fields

OSC330D

Selection criteria

Specify Grouping and separator

Define resulting output queues

Specify automatic start options

Specify automatic start scheduling

Qsysopr

Specify job priority

Specify output queue for processed spooled files

Archive

Working with Joint Reports

Compose Joint Report

Is used solely in connection with the displaying of a list

Designing a Report Composition

Descriptive text for the report you wish to make. This text

Reports in this file-set

=Empty Overlay front

= Overlay with index

Font, text

=Overlay + spool entry

Indention, page no

Font, page no

Print Report

Test Print Report Overlays

Test Print Report, 1 Page per Overlay

Link name

Corresponding print-out

F12

User’s Manual for InterForm400

Administering InterForm400 Environment and Users

Appoint Administrator

Appoint InterForm 400 Administrator

Hpii Hpiid Hpiip Hpiii Hpiiid

Configure InterForm

Hpiiip HP4 HP4D HP4PJL HP4DPJL

Legal = Monarch

Letter

= Ledger

Executive

Do you want to use DDM to InterForm files on other AS/400

These output queues

Work with InterForm400 Users

Work with file sets

Connect Users with Overlay File Sets

User profile Peter

Press F3 when all required file sets have been assigned

User’s Manual for InterForm400

Working with Fonts

Resident Fonts

Work with Fonts

Description of Additional Fonts

APF370D

=Propotional spaced

Example of Defining a Resident Printer font

Override spacing

Font 7001 Other fonts

Work with soft fonts for PCL

Place into flash

Import a True Type Font

F4=List F3=Exit F12=Cancel

File transfer HP SFP Font files from a PC

Auto download Soft Fonts

HP4

Hpiiship

Allways Allways *PRI *SEC *NEVER

InterForm400 Predefined Soft Fonts

Create barcode soft font

Support of barcodes is described on

Ocrb Soft Font Font ID

Micr Soft Font Font ID

Ocra Soft Fonts

PGR332D

User’s Manual for InterForm400

Barcode Support

Calculating barcode height

Extended code

Create bar code soft font

Code

Code 128 and EAN128

Postnet Barcode

Interleaved 2

EAN8, EAN13 and UPC-A

Line separator

Datamatrix barcodes

Assigning Font ID’s to Barcode Softfonts

GEN

Example of editing a font ID for Code39 barcode

Downloading a Barcode Soft Font

Code39 can be defined in the font ID interval

User’s Manual for InterForm400

Getting Familiar with Soft-fonts and Barcodes

Installing the Arial True Type Font

FNT431D

ARIAL.TTF

Creating the Code128 Barcode

Create font ID for the Arial soft-font

Define auto-download of fonts Arial and Ocrb

Enter 6=update output queues for the Printer group *PCL

PCL

5001 F4=List

CODE128AAA

Arial

Testing the Barcodes in an Overlay

0003

HLD Demo

Qprint Peter

Testfont

44A2971

Page/Line 1/28

44A9032

Description of Zebra fonts

Work with Zebra fonts

Zebra flash memory’

CG Triumvirate

Defining barcodes for Zebra printers

Dot matrix

Datamatrix barcode

Columns/Rows To encode

Relative width

Using soft fonts for printing on Zebra

Height The height of the font

Special Edcdic

Frutbowe

Work with Zebra soft fonts

Frutboce

Logofont

Download a soft font into flash memory

Work with fonts in Zebra flash memory

Zebra Qusrsys Courier

Delete a soft font from flash memory

Substitution Zebra internal fonts

Zebra Qusrsys

Initiate Zebra flash memory and reload fonts and images

This screen is shown

Initiate Zebra flash memory and reload fonts and images

User’s Manual for InterForm400

Work with images

PP.TIF

Working with black and white images

Importing black and white images

PRO1.TIF

Working with color images

BMP100D

Import color images

Logo

Work with Zebra images

Work with Zebra images

Newlogo

Work with images in Zebra flash memory

Zebra Qusrsys Logo

Work with PCL Files

PCL100D

Cebit

Import PCL file

Press F6 to load a PCL file into InterForm400

User’s Manual for InterForm400

Change the definition of the colors

Work with palette

PAL100D

User’s Manual for InterForm400

Paper type to PCL-drawer conversion

Work with paper control options

Hpii Qusrsys PRT01

Output Sorter Bin Support

Defining an Output Sorter Bin for a User

Sorter Type

Default output bin

Output queue holding the HP5Si or Lexmark Optra printer

To 11 can be defined for a HP5Si

PRT02

Qsecofr

009

Overlay

User profile Binno

008

Import Certificates

Service Functions

Create Demo Spool Entry

Display All Displayable Characters

Save spooled file to the folder APF3812

Print Saved Spooled File from the folder APF3812

Print Resource X-reference

Work with Journaling

Export of InterForm400 resources

Copy resources to export library

This option is used to create a distribution file

Work with resources in export library

Work with distribution

EXP600D

Import of InterForm400 Resources

Work with resources in import library

Importd

Transfer resources to the production library

EXPORT.001

Exists

Working with resources in import library

=Rename file-set

PTF100D

Install/upgrade InterWord

Apply PTF from folder APF3812

GO DCA400/INTERWORD

Install InterForm Designer on your PC

Install Swiftview at drive C

Prepare server to support InterForm Designer

User’s Manual for InterForm400

Selnam

Kartset

Kliche

Vrsion PRI PRI, *SEC

Fromadr

BCC

PRT *PRT, *DSP

User’s Manual for InterForm400

APF3812Mail/Log

APF3812Mail/MergeLog APF3812Mail/OutBox

User’s Manual for InterForm400

User’s Manual for InterForm400

System Requirements

Appendix a Installation

First Time Installation

License Codes

Release Update

Testaut KSE

INS0104 InterForm Version 2006M01

INS0121 InterForm Version 2006M01

INS0123 InterForm Version 2006M01

Upgrade remote sites

Relations to Other Applications

Printing

Performance

Processing

User’s Manual for InterForm400

Attachment Methods

System Configuration by Auto Configuration

Appendix B Attaching Printers to the iSeries

Attaching through a Twinax Protocol Converter

Start the printer writer with the following command

Configuring a Printer Device Manually

From 5219 to

Changing Device Description from 5219 to

Make a note of the Port Number 2, the Switch setting 3

Now you must vary off the device by the following command

Attached controller CTL01

Attaching through a TCP/IP Raw Socket Port 9100/3700

Attaching through a 5250 Terminal

Start the printer writer again by the following command

Client Access/400 for Windows 95/NT

Following CL command will enable host print transform

Attaching through a PC Printer Port

Remote System

Enter the following command to change the queue

Attaching through a TCP/IP LPD Printer Server Remote Writer

Remote Printer Queue

Attaching through a TN5250E Print Client

Printer Writers

Testing the Connection

Trouble Shooting

Remote Writers

User’s Manual for InterForm400

Appendix C Printer Types

Black and white printer types

HP4

Color printer types

Zebra printer types

To use page range on the merged spooled file see tip above

Cassette Mapping Drawers

Select Drawer using Paper Type

Selecting drawer by drawer number

User’s Manual for InterForm400

Appendix D Interfaces Protocol Converters

WS31N, WS347N

Appendix E Codepage Support

Country Ebcdic Codepage Euro codepage

User’s Manual for InterForm400

Appendix F Font-ID Information

IBM 3812 font-ID Information

Font-ID

IBM Compatible Font List

Font Name

110

245

230

229

252

Shipped Zebra Fonts

Font number Description

Typefaces known by PCL-Printers

Font Description Typeface Number

User’s Manual for InterForm400

Appendix G Limitations of the Light Version

Following are rules given for the Light version

User’s Manual for InterForm400

Appendix H Commands in Spooled Files

Command line Overview

VAN

TXT

FNT

PCL

BLA

BMK

Example of using Escape Commands in the Data Stream

040 1/240 of an inch *INPUT Rotation

User’s Manual for InterForm400

Add NetServer Printer share Command

NetServer Commands

Add Netserver File Share Command

Change Netserver Attributes Command

Remove NetServer share Command

Save/Restore and Export/Import Commands

End Netserver Command

Start Netserver Command

Restore Library from Folder Command

Import Chart Command

Save Library to Folder Command

Clear Link to Joint Report Command

Joint Report Commands

Link Joint Report Command

End Auto Forms Control Job Command

AFC and OSC Commands

Print Joint Report Command

Apflnk command which contains the following parameters

Transform *AFPDS print Command

Start Auto Forms Control Job Command

Start OSC Job Command

APF3812 Overlay Merge Command

Copy CPI Spooled File Command

Builder Spooled File Command

PageBuilder program that the command is to call for each

Each of the Data fields are defined like this

Return length

Find string

String length

Minimum/maximum line

Crtpbsplf call option STR, PAG or END

Convert PCL Spooled File Command

JOB

Value from the Appidparm keyword

Labels / Continuous Mediatrack

Merge Spooled File ZPL Command

Print mode Printmode

Select *LABELS if the media contains of separate labels

Spooled File Inspector SFI

Print Ascii File Command

Split Spooled File Command

Media type Mediatype

SFI110D

Zip Stream Files Command

Error

Last ANY, *FIRST, *LAST

Current

Other Utility Commands

Edit Print Command

From stream

Fromoutq

APF Work Output Queue Command

Filnvn Select

Tooutq

Display Black/White image Command

HP Macro Command

Noedit

MACROnnnnn, where nnnnn is the macro ID. The description

Into the Hpmacro command

Pages *YES or only when called from a macro definition

Defines the name of the file-set, in which you have defined

PCL-file from folder to Member Command

Import InterForm400 Resources Command

Refer to page 477 for more information of this command

Print PCL-member Command

Print Tiff File Command

Send Mail Commnd Work Mail addresses Command

Print X-Ref List Command

Work with Profile Jobs Command

Work with Stream File Locks

TIF-file from folder to member Command

User’s Manual for InterForm400

Merging with OfficeVision jobs with limited overlay features

Downloading the overlay as a macro

User’s Manual for InterForm400

Appendix K Forms Server for non-AS/400 environments

Adding overlays to *ASCII PC printjobs PCL

Qprint Display Spool File

Defining a Virtual printer in Client Access

User’s Manual for InterForm400

SwiftView licenses

Command for 10. Work with actual output queue is

PCL viewing

Requirements for running SwiftView

Share the folder system as Qdls with this command

Setting up Client Access Express, enabling PCL-viewing

Setting up a SwiftView user

Use the command

NetServer commands

Add NetServer File Share

Troubleshooting problems using SwiftView

NetServer share commands

Add NetServer Printer Share

User’s Manual for InterForm400

Appendix M InterForm400 charts

Work with Charts command, Wrkcht

Press F6 to create a new chart

BAR, *LINE

CHA300D

Define general layout

Mybar

Define layout of the X-axis

CHX100D

Define X-axis points and X-axis groups

MON

Axis point ID

Work with X-axis points

Seq number

Text font/color

Define layout of the Y1 and Y2-axis

Values font/color

For charts with type *LINE the screen looks like this

CHS100D

Line width

Use Y1/Y2-axis

Line type

Pattern color

Marker Description

CHS200D

General description of the &&CHA commands

&&CHA Chart commands

General format of the &&CHA commands

Command examples

Create internal chart Cric

Create/delete internal chart commands

Delete internal chart Dlic

Load commands

Load external chart Loec

Define general layout Gnlo

General layout commands

Desciption

Axis commands

Define X-axis layout Xalo

Y1-/Y2-axis commands

Define Y1-axis/Y2-axis layout Y1LO 01/Y2LO

Define Y1-axis/Y2-axis layout Y1LO 02/Y2LO

Add/change X-axis group layout Xglo

Axis group commands

Deletes a X-axis group

Axis point commands

Add/change observation set layout Oslo

Observation set commands

Delete observation set Dlos

Clear observation set data Clos

Data commands

Add/change data by ID Osda

Print sample chart Prsm

Print chart commands

Print chart Prch

END

Setup of Smtp

Any sequence Pos 20-30 = Keyword

Combining Smtp and Domino/400 on the same machine

Requirements for the PC

Requirements for the Graphical Designer

Requirements for the iSeries AS/400

Requirements for the network

Service Port number Microsoft-DS 445

Installing the Graphical Designer

Installing Java Environment

Limitations of the Graphical Designer

Starting the Graphical Designer

Start designing an overlay

Edit an existing overlay

Create a new overlay

Open a Spooled File

Previewing the result in Acrobat reader or SwiftView

Settings and tools for the design

Changing the displayed size

Other Design preferences

Designing for 203 or 300 DPI For Zebra overlays only

Designing the overlay

Decide the sort key for the font listing

Zebra

Temperature

Activate duplex if needed. Not available for ZPL output

Copy Management

Spool view

Result view

User’s Manual for InterForm400

Inserting design elements

User’s Manual for InterForm400

Local save in the designer

Movement of elements in the result view

Grouping and ungrouping elements

You can ungroup the elements in these manners

User’s Manual for InterForm400

Description

Multiple Export Libraries MEL feature

Import InterForm Ressources Impapfrsc command

Activation/deactivation

Parameters

Restrictions

Examples

Error code Description

Sample scenario of using MEL and the Impapfrsc command

Escape messages

Crypto Access Provider 128-bit for AS/400

Base

E-mail finishing definition

Technical details

Import Certificates

Refer to

Comp COMP, *ORG, *PERS

CER302D

Public

Recommendations related to Java Performance

OS/400 System values

OS/400 Subsystem settings

Maxact for the *BASE pool

User’s Manual for InterForm400

Index

APF3812/PCLTOMBR

PCL

Outq

Strnetsvr