Installation Conditions

D. Secured at four points (with mounting hardware attached horizontally)

(Take proper precautions to prevent pinching the power cord or signal cables.)

3.2.4 Mounting surface warping

The display section incorporates glass. Before mounting the product, using hardware other than that provided by Pioneer, perform the following to confirm that the display is free from warps exceeding 1 mm*.

* Regarding the 1mm limit

The frame of the display may have a warp of up to 3mm. If the total warp (the warp of the frame plus the warp of the mount surface) exceeds 4mm then the glass in the display may be put under excessive stress. In order to ensure that the total warp is less than 4mm, you should make sure that the warp of the mount surface is less than 1mm.

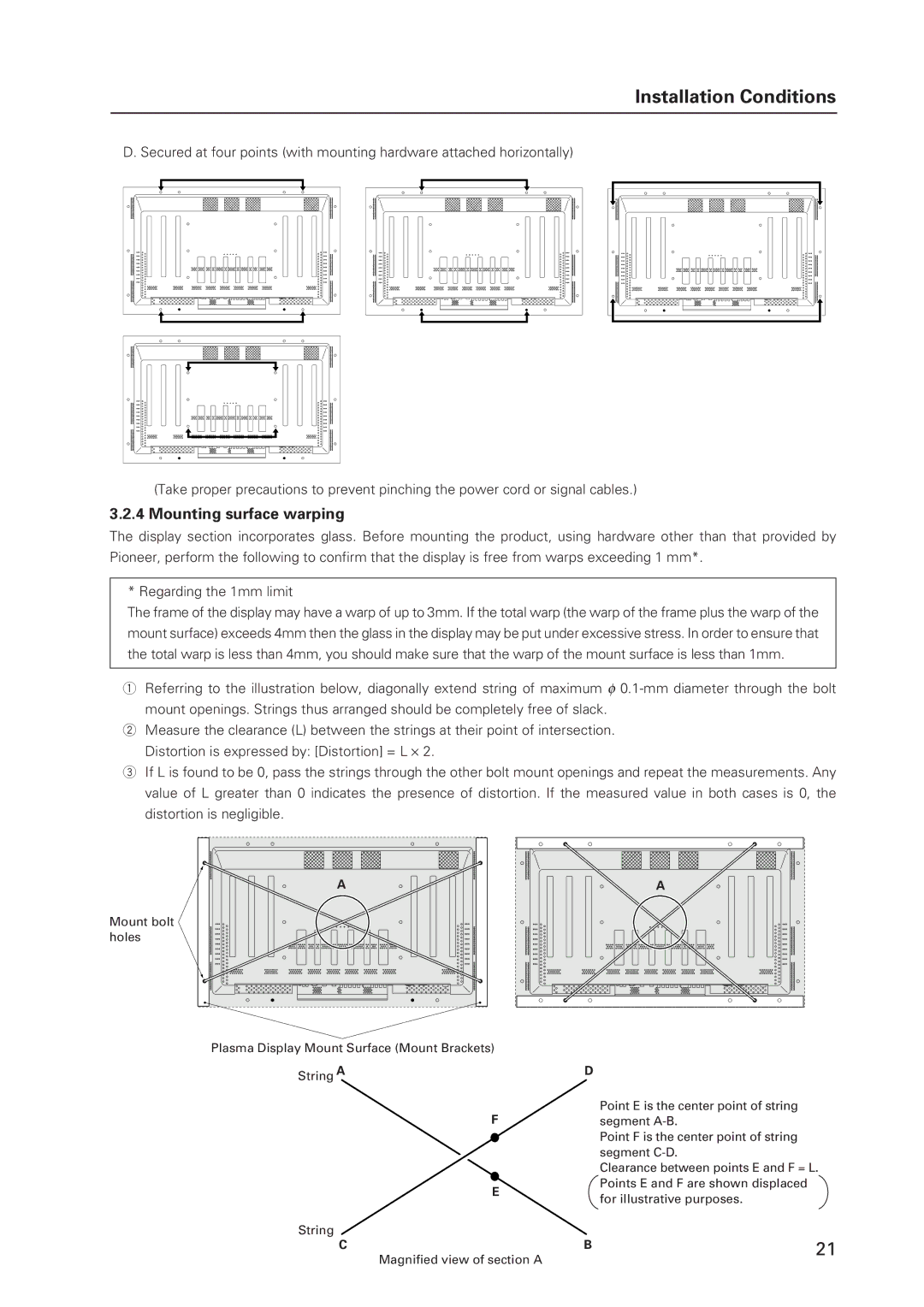

1Referring to the illustration below, diagonally extend string of maximum φ

mount openings. Strings thus arranged should be completely free of slack.

2Measure the clearance (L) between the strings at their point of intersection.

Distortion is expressed by: [Distortion] = L × 2.

3If L is found to be 0, pass the strings through the other bolt mount openings and repeat the measurements. Any value of L greater than 0 indicates the presence of distortion. If the measured value in both cases is 0, the distortion is negligible.

Mount bolt

holes

A | A |

Plasma Display Mount Surface (Mount Brackets)

String A

F

E

String

D

Point E is the center point of string segment

Point F is the center point of string segment

Clearance between points E and F = L. Points E and F are shown displaced for illustrative purposes.

C | B | 21 |

| Magnified view of section A | |

|

|