9480 CARROLL PARK DRIVE SAN DIEGO, CA USA

TELEDYNE ADVANCED POLLUTION INSTRUMENTATION

MODEL 300E FAMILY CARBON MONOXIDE ANALYZERS

Operation Manual

Page

SAFETY MESSAGES

This page intentionally left blank

Safety Messages

WARRANTY POLICY 02024D

WARRANTY

CAUTION – Avoid Warranty Invalidation

COVERAGE

04288D DCN5752

This page intentionally left blank

instrument

ABOUT THIS MANUAL

Part No

Name/Description

2010 June

REVISION HISTORY

Document

Change Summary

Revision History

viii

Revision History

This page intentionally left blank

Table of Contents

TABLE OF CONTENTS

6. BASIC OPERATION

PART II – OPERATING INSTRUCTIONS

8. REMOTE OPERATION

7. ADVANCED FEATURES

9. CALIBRATION PROCEDURES

PART III – TECHNICAL INFORMATION

10. EPA CALIBRATION PROTOCOL

xiii

11. THEORY OF OPERATION

13. TROUBLESHOOTING & REPAIR

12. MAINTENANCE SCHEDULE & PROCEDURES

14. A PRIMER ON ELECTRO-STATICDISCHARGE

LIST OF FIGURES

LIST OF APPENDICES

TABLE OF CONTENTS

xviii

LIST OF TABLES

Table

This page intentionally left blank

TABLE OF CONTENTS

GENERAL INFORMATION

PART - GENERAL INFORMATION

Part

This page intentionally left blank

Part

GENERAL INFORMATION

1.1.M300E FAMILY OVERVIEW

1.INTRODUCTION

1.2.ADDITIONAL DOCUMENTATION

TABLE OF CONTENTS

1.2.1.USING THIS MANUAL

PART I – GENERAL INFORMATION

SPECIFICATIONS AND WARRANTY

APPENDICES

PART III – TECHNICAL INFORMATION

ADVANCED FEATURES OF THE M300E/EM ANALYZER

MAINTENANCE SCHEDULE AND PROCEDURES

Table 2-1:M 300E/300EM Basic Unit Specifications

2.SPECIFICATIONS AND APPROVALS

2.1.SPECIFICATIONS

2.2.EPA EQUIVALENCY DESIGNATION

2.3.TUV DESIGNATION

2.4.2.SAFETY COMPLIANCE

2.4.CE MARK COMPLIANCE

2.4.1.EMISSIONS COMPLIANCE

This page intentionally left blank

Specifications and Approvals

3.1.M300E/EM ANALYZER LAYOUT

3.GETTING STARTED

Figure

Front Panel Layout

Figure

Table 3-2:Inlet / Outlet Connector Nomenclature

Rear Panel Layout

SAMPLE

Figure 3-3:Internal Layout – M300E

Getting Started

Getting Started

Figure 3-5:Optical Bench Layout

Figure 3-6:M300E/EM Internal Gas Flow Basic Configuration

GENERAL SAFETY HAZARD

3.2.UNPACKING THE M300E/EM ANALYZER

power CAUTION – Avoid Warranty Invalidation

ELECTRICAL SHOCK HAZARD

3.3.ELECTRICAL CONNECTIONS

3.3.1.POWER CONNECTION

3.2.1.VENTILATION CLEARANCE

Do not defeat the ground wire on power plug

3.3.2.ANALOG OUTPUT CONNECTIONS

3.3.3.CONNECTING THE STATUS OUTPUTS

Analog Output Connector

Figure

Table 3-5:Status Output Signals

Figure 3-8:Status Output Connector

STATUS

REAR PANEL

Control Input Connector

3.3.4.CONNECTING THE CONTROL INPUTS

Table 3-6:Control Input Signals

Figure

3.3.6.CONNECTING TO A LAN OR THE INTERNET

3.3.5.CONNECTING THE SERIAL PORTS

3.3.7.CONNECTING TO A MULTIDROP NETWORK

3.4.PNEUMATIC CONNECTIONS

3.4.1.2.Span Gas

exhaust and supply gas lines

GENERAL SAFETY HAZARD

glass, stainless steel or brass

area or shelter surrounding the instrument

of the analyzer

3.4.2.1.Sample Gas Source

3.4.2.2.Calibration Gas Sources

3.4.2.3.Input Gas Venting

3.5.INITIAL OPERATION

3.4.2.4.Exhaust Outlet

using the procedures defined in Section

configuration and calibration data

3.5.1.STARTUP

System waits 3 seconds then

automatically begins its initialization routine

3.5.3.WARNING MESSAGES

3.5.2.WARM UP

Table 3-9:Possible Warning Messages at Start-Up

3.5.4.FUNCTIONAL CHECK

installed

3.6.INITIAL CALIBRATION OF THE M300E/EM

3.6.1.INTERFERENTS FOR CO2 MEASUREMENTS

If it is not, press

is set for SNGL

SINGL

ENTR

3.6.2.2.Dilution Ratio Set Up

3.6.2.3.Set CO Span Gas Concentration

STABIL= XXXX PPM

3.6.2.4.Zero/Span Calibration

STABIL= XXXX PPM

STABIL= XXXX PPM

3.6.4.CO2 SENSOR CALIBRATION PROCEDURE

3.6.3.O2 SENSOR CALIBRATION PROCEDURE

The M300E/EM Analyzer is now ready for operation

THANK YOU

4.1.FAQ’S

4.FREQUENTLY ASKED QUESTIONS

Description/Definition

4.2.GLOSSARY

Term

Description/Definition

Term

Description/Definition

Term

5.2.RACK MOUNT KITS OPT 20 TO OPT

5.OPTIONAL HARDWARE AND SOFTWARE

5.1.EXTERNAL PUMPS OPTIONS 10A-10E,11,

GENERAL SAFETY HAZARD

5.3.CARRYING STRAP/HANDLE OPT

5.4.CURRENT LOOP ANALOG OUTPUTS OPTION

Figure 5-2:Current Loop Option Installed on the Motherboard

5.6.CALIBRATION VALVES OPTIONS 50A, 50B, 50E, 50H

5.5.EXPENDABLES AND SPARES KITS OPTIONS 42A,

5.6.2.ZERO/SPAN VALVE OPTION 50A

5.6.1.1.Gas Flow Rate

Figure

5.6.2.1.Internal Pneumatics OPT 50A

5.6.2.3.Input Gas Venting

5.6.2.2.Pneumatic Set Up OPT 50A

5.6.2.4.Exhaust Outlet

SAMPLE GAS SOURCE

Figure

5.6.3.ZERO/SPAN/SHUTOFF VALVE OPTION 50B

5.6.3.1.Internal Pneumatics OPT 50B

SAMPLE GAS SOURCE

5.6.3.2.Pneumatic Set Up OPT 50B

CALIBRATION GAS SOURCES SPAN GAS

ZERO AIR

5.6.4.1.Internal Pneumatics OPT 50H

SAMPLE GAS SOURCE

5.6.4.2.Pneumatic Set Up OPT 50H

CALIBRATION GAS SOURCES SPAN GAS

ZERO AIR

Scrubber

5.6.5.1.Internal Pneumatics OPT 50E

SAMPLE GAS SOURCE

5.6.5.2.Pneumatic Set Up OPT 50E

CALIBRATION GAS SOURCES SPAN GAS

ZERO AIR

5.7.1.RS-232MODEM CABLE OPTION 60A

5.7.COMMUNICATION OPTIONS

5.7.2.RS-232MULTIDROP OPTION

Table 5-5:M300E/EM Modem Cable Options

Figure 5-12:M300E/EM Ethernet Card

5.7.3.ETHERNET OPTION 63A

5.8.1.OXYGEN SENSOR OPTION 65A

5.8.SECOND GAS SENSORS

5.7.4.ETHERNET + MULTIDROP OPT 63C

5.8.1.3.Pneumatic Operation of the O2 Sensor

5.8.1.2.Operation within the M300E/EM Analyzer

5.9.CARBON DIOXIDE SENSOR OPTION 67A

5.9.1.CO2 SENSOR RANGES AND SPECIFICATIONS

5.9.2.THEORY OF OPERATION

5.9.2.1.NDIR measurement of CO2

Figure 5-16 CO2 sensor Theory of Operation

5.9.2.2.Operation within the M300E/EM Analyzer

5.9.2.3.Pneumatic Operation of the CO2 Sensor

5.9.2.4.Electronic Operation of the CO2 Sensor

Figure 5-19:Concentration Alarm Relay

5.10.CONCENTRATION ALARM RELAY OPTION

CO Alarm 1 = 20 PPM CO Alarm 2 = 100 PPM

5.11.2.MAINTENANCE MODE SWITCH

5.11.SPECIAL FEATURES

5.11.3.SECOND LANGUAGE SWITCH

5.11.1.DILUTION RATIO OPTION

OPERATING INSTRUCTIONS

PART – OPERATING INSTRUCTIONS

This page intentionally left blank

OPERATING INSTRUCTIONS

6.1.OVERVIEW OF OPERATING MODES

6.BASIC OPERATION

MODE

EXPLANATION

Figure 6-2:Viewing M300E/EM Test Functions

6.2.SAMPLE MODE

analyzer’s inability to calculate it

Test Functions Defined

Table

MEANING

6.3.WARNING MESSAGES

The IR source may be faulty

Table 6-3:List of Warning Messages

currently selected reporting range EXAMPLES

6.4.CALIBRATION MODE

Primary Setup Mode Features and Functions

6.5.SETUP MODE

Secondary Setup Mode Features and Functions

instrument until the ENTR Key is pressed

6.5.2.SETUP ACAL: AUTOMATIC CALIBRATION

6.5.1.SETUP CFG: CONFIGURATION INFORMATION

Table

6.5.3.SETUP PASS: PASSWORD FEATURE

Password Levels

04288D DCN5752

Basic Operation

the required number code

6.5.4.1.Setting the internal Clock’s Time and Day

6.5.4.2.Adjusting the Internal Clock’s Speed

MODEL

Table 6-7:M300E Family Physical range by Model

RANGE

M300E

ANALOG OUT

6.6.2.ANALOG OUTPUT RANGES FOR CO CONCENTRATION

Figure 6-4:Analog Output Connector Pin Out

SNGL

6.6.3.REPORTING RANGE MODES

DUAL

AUTO

Page

The two ranges must be independently calibrated

concentrations

Basic Operation

Toggle these keys to

discards the new setting accepts the new setting

select the upper limit for the reporting range

computing the CO concentration

reporting units

Basic Operation

Pressure STP

sufficient

Using the dilution ratio option is a 4-stepprocess

This page intentionally left blank

Basic Operation

7.1.1.IDAS STATUS

7.ADVANCED FEATURES

LED STATE

IDAS STATUS

Table 7-2:iDAS Data Channel Properties

7.1.2.IDAS STRUCTURE

7.1.2.1.iDAS Channels

7.1.3.DEFAULT IDAS CHANNELS

Figure 7-1:Default iDAS Channel Setup

Continue pressing to view remaining iDAS channels

Channel No.: NAME: CONC TRIGGER EVENT: ATIMER

0 CONC: ATIMER, 1,

7.1.5.1.Editing iDAS Data Channel Names

7.1.5.2.Editing iDAS Triggering Events

Table 7-3:iDAS Data Parameter Functions

7.1.5.3.Editing iDAS Parameters

found in Appendix A-5

When the STORE NUM SAMPLES feature is turned on, the instrument will store how many

7.1.5.4.Editing Sample Period and Report Period

In AVG, SDEV, MIN or MAX sample modes see Section 7.1.5.3, the settings for the Sample Period and the Report Period determine the number of data points used each time the parameter is calculated, stored and reported to the COMM ports

7.1.5.6.Editing the Number of Records

7.1.5.7.RS-232Report Function

7.1.5.8.Enabling/Disabling the HOLDOFF Feature

7.1.6.DISABLING/ENABLING DATA CHANNELS

7.1.5.9.The Compact Report Feature

7.1.5.10.The Starting Date Feature

7.1.7.1.iDAS Configuration Using APICOM

7.1.7.REMOTE IDAS CONFIGURATION

attempting any iDAS changes

DEFAULT

7.2.SETUP MORE VARS: INTERNAL VARIABLES VARS

Table 7-4:Variable Names VARS

ALLOWED

accepts the new setting

setting

SETUP

SETUP

SIGNAL I/O

Table 7-5:Diagnostic Mode DIAG Functions

CONFIGURATION

DIAG I/O

7.3.1.ACCESSING THE DIAGNOSTIC FEATURES

Table 7-6:DIAG - Analog I/O Functions

7.4.USING THE M300E/EM ANALYZER’S ANALOG OUTPUTS

SUB MENU

OUTPUT

Page

RANGE NAME

Table 7-7:Analog Output Voltage Range Min/Max

RANGE SPAN

MINIMUM OUTPUT

04288D DCN5752

7.4.3.CALIBRATION OF THE ANALOG OUTPUTS

See Section

Manual calibration should be used for any analog output set for a 0.1V output range or in cases where

Page

The menu for manually adjusting the analog output signal level will only appear if the AUTO-CALfeature

Advanced Features

ground

GENERAL SAFETY HAZARD

Advanced Features

Voltage across

% FS

Resistor for 2-20mA

Resistor for 4-20mA

Page

Page

DESCRIPTION

TEST CHANNEL

ZERO

FULL SCALE

new setting

setting

SETUP

SETUP

7.4.7.AIN CALIBRATION

LIMIT SET POINT1

ALARM

STATUS

This page intentionally left blank

Advanced Features

8.1.1.RS-232DTE AND DCE COMMUNICATION

8.1.2.COMM PORT DEFAULT SETTINGS

8.REMOTE OPERATION

Figure 8-1:Default Pin Assignments for Back Panel COMM Port connectors RS-232DCE & DTE

8.1.3.COMM PORT BAUD RATE

8192

8.1.4.COMM PORT COMMUNICATION MODES

2048

1024

Remote Operation

8.1.5.COMM PORT TESTING

8.1.6.MACHINE ID

Table 8-2:Terminal Mode Software Commands

8.1.7.1.Help Commands in Terminal Mode

8.1.7.TERMINAL OPERATING MODES

8.1.7.3.Data Types

8.1.7.2.Command Syntax

X ID COMMAND <CR>

Table 8-3:Teledyne API’s Serial I/O Command Types

X DDD:HH:MM Id MESSAGE<CRLF>

8.1.7.4.Status Reporting

940331 is the default password

8.1.7.5.COMM Port Password Security

LOGON

V RS-232 PASS=NNNNNN

8.2.MULTIDROP RS-232SET UP

CALIBRATOR

Host

TAPI Analyzer

Last INSTRUMENT

Figure 8-5:CPU RS-485Setup

8.3.RS-485CONFIGURATION OF COM2

RX/TX RX/TX+

The DCE/DTE switch has no effect on COM2

Female DB-9COM2

Table 8-4:Ethernet Status Indicators

8.4.REMOTE ACCESS VIA THE ETHERNET

DEFAULT STATE

Table 8-5:LAN/Internet Configuration Properties

See your network administrator

PROPERTY

Remote Operation

∙Your LAN is not running a DHCP software package

SETUP

ON/OFF

PRIMARY SETUP MENU

SETUP

Moves the cursor one character to the left or

FUNCTION

right

Inserts a character before the cursor location

FUNCTION

8.4.4.CHANGING THE ANALYZER’S HOSTNAME

ENTR

EXIT

Actions

8.5.MODBUS SETUP

Minimum Requirements

8.5.1.REMOTE ACCESS BY MODEM

AT Y0 &D0 &H0 &I0 S0=2 &B0 &N6 &M0 E0 Q1 &W0

To initialize the modem press

Remote Operation

Protocol network

8.6.2.HESSEN COMM PORT CONFIGURATION

8.6.1.GENERAL OVERVIEW OF HESSEN PROTOCOL

8.6.3.ACTIVATING HESSEN PROTOCOL

8.6.4.SELECTING A HESSEN PROTOCOL TYPE

MODE ID

8.6.5.SETTING THE HESSEN PROTOCOL RESPONSE MODE

MODE DESCRIPTION

TEXT

GAS TYPE,RANGE,GAS ID,REPORTED

8.6.6.HESSEN PROTOCOL GAS LIST ENTRIES

CO, 0, 310, REPORTED CO2, 0, 311, REPORTED

O2, 0, 312, REPORTED

8.6.6.2.Editing or Adding HESSEN Gas List Entries

8.6.6.3.Deleting HESSEN Gas List Entries

Table 8-8:Default Hessen Status Flag Assignments

8.6.7.SETTING HESSEN PROTOCOL STATUS FLAGS

DEFAULT BIT

STATUS FLAG NAME

8.6.8.INSTRUMENT ID CODE

8.7.APICOM REMOTE CONTROL PROGRAM

Calibration Procedures

9.CALIBRATION PROCEDURES

SECTION 9.1 – BEFORE CALIBRATION

SECTION 9.5 – CO CALIBRATION QUALITY ANALYSIS

9.1.2.CALIBRATION GASES

9.1.BEFORE CALIBRATION

9.1.2.1.Zero Air

troubleshooting tips

9.1.2.2.Span Gas

9.1.3.DATA RECORDING DEVICES

9.1.2.3.Traceability

calibration

and alters the instrument’s Calibration

Calibration Procedures

allowed for a reliable calibration

9.2.2.PERFORMING A BASIC MANUAL CALIBRATION CHECK

See Section 12 for troubleshooting tips

the bottle

9.2.3.PERFORMING A BASIC MANUAL CALIBRATION

the SPAN gas

Calibration Procedures

9.2.3.2.Zero/Span Point Calibration Procedure

9.3.MANUAL CALIBRATION WITH ZERO/SPAN VALVES

9.3.1.SETUP FOR CALIBRATION USING VALVE OPTIONS

Figure 9-5:Pneumatic Connections – Option 51B: Zero/Span Calibration Valves

Calibration Procedures

the bottle

9.3.3.MANUAL CALIBRATION USING VALVE OPTIONS

the SPAN gas

9.3.3.2.Zero/Span Point Calibration Procedure

Table 9-2:AUTOCAL Modes

9.4.AUTOMATIC ZERO/SPAN CAL/CHECK AUTOCAL

MODE NAME

ACTION

TIMER ENABLED

Table 9-3:AutoCal Attribute Setup Parameters

ATTRIBUTE

ACTION

VALUE

MODE AND

COMMENT

ZERO-SPAN

from the display

SETUP X.X STARTING DATE: 04–SEP–08

for each

Table 9-5:Calibration Data Quality Evaluation

9.5.CO CALIBRATION QUALITY

FUNCTION

MINIMUM VALUE

SETUP

9.6.1.DARK CALIBRATION TEST

SETUP

DAS RNGE PASS CLK MORE

atmospheric pressure

9.6.2.PRESSURE CALIBRATION

9.6.3.FLOW CALIBRATION

9.6.4.ELECTRICAL TEST CALIBRATION

9.7.1.1.O2 Calibration Setup

9.7.1.O2 SENSOR CALIBRATION PROCEDURE

9.7.CALIBRATION OF OPTIONAL SENSORS

Figure 9-7:O2 Sensor Calibration Set Up

Set the expected O2 span gas concentration

9.7.1.2.Set O2 Span Gas Concentration

complete

9.7.1.3.Activate O2 Sensor Stability Function

To perform the zero/span calibration procedure

9.7.1.4.O2ZERO/SPAN CALIBRATION

9.7.2.1.CO2 Calibration Setup

9.7.2.CO2 SENSOR CALIBRATION PROCEDURE

9.7.2.2.Set CO2 Span Gas Concentration

Figure 9-8:CO2 Sensor Calibration Set Up

complete

9.7.2.3.Activate CO2 Sensor Stability Function

Calibration Procedures

9.7.2.4.CO2 Zero/Span Calibration

This page intentionally left blank

Calibration Procedures

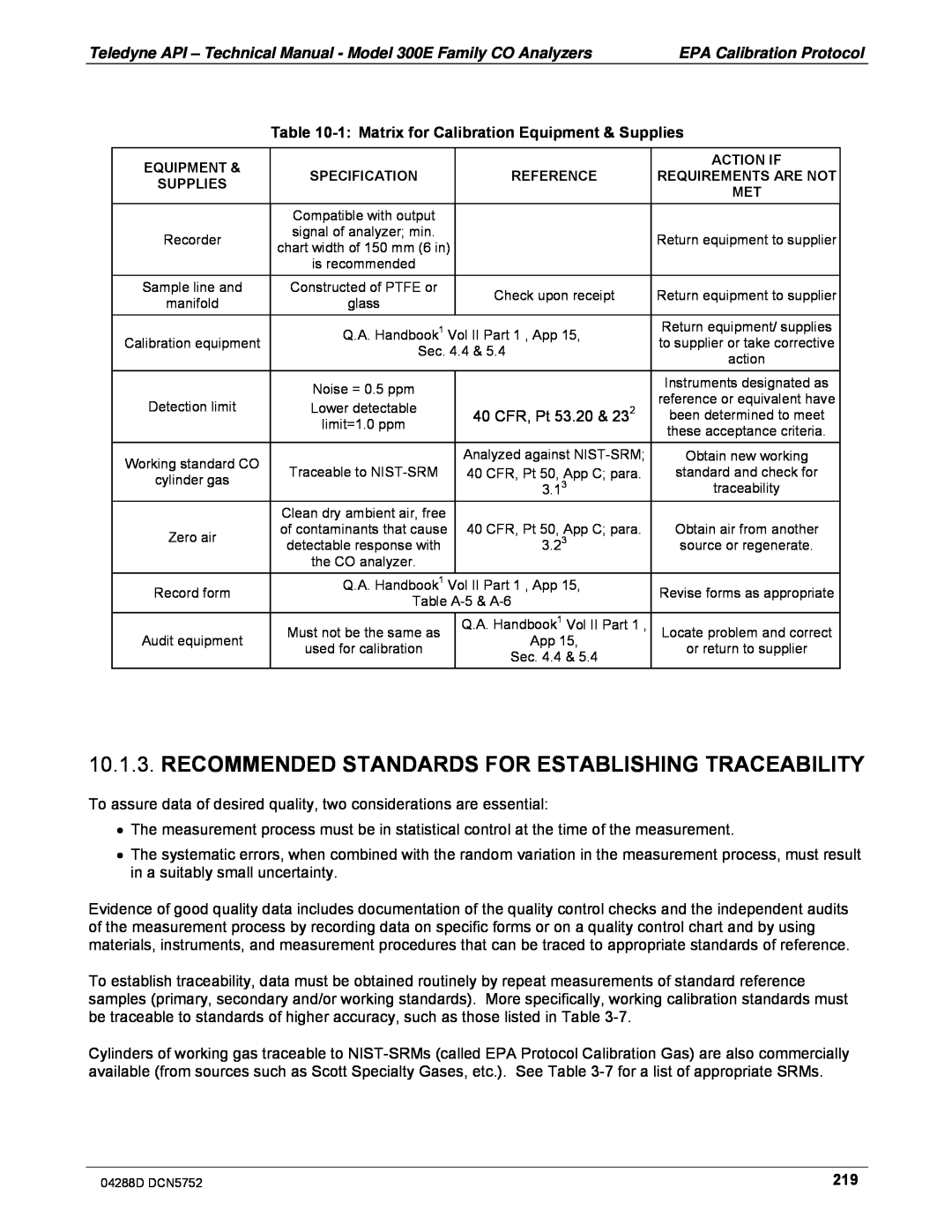

10.1.CALIBRATION REQUIREMENTS

10.EPA CALIBRATION PROTOCOL

10.1.2.2.Spare Parts and Expendable Supplies

10.1.2.1.Data Recording Device

Page

10.1.5.LEVEL 1 CALIBRATIONS VERSUS LEVEL 2 CHECKS

10.1.4.CALIBRATION FREQUENCY

Q.A. Handbook1 Vol II, Part1, Section 12.3 &

10.2.ZERO AND SPAN CHECKS

10.2.2.PRECISION CHECK

10.2.1.ZERO/SPAN CHECK PROCEDURES

10.3.PRECISIONS CALIBRATION

10.3.1.PRECISION CALIBRATION PROCEDURES

10.4.AUDITING PROCEDURE

10.4.1.CALIBRATION AUDIT

10.4.2.DATA REDUCTION AUDIT

10.5.1.LINEARITY TEST

10.5.DYNAMIC MULTIPOINT CALIBRATION PROCEDURE

10.4.3.SYSTEM AUDIT/VALIDATION

∙Leaks ∙Correct flow

10.6.REFERENCES

TECHNICAL INFORMATION

PART – TECHNICAL INFORMATION

PART

This page intentionally left blank

Technical information

11.1.MEASUREMENT METHOD

11.THEORY OF OPERATION

11.2.MEASUREMENT FUNDAMENTALS

11.1.1.BEER’S LAW

Figure 11-2:GFC Wheel

11.2.1.GAS FILTER CORRELATION

Figure 11-1:Measurement Fundamentals

11.2.1.1.The GFC Wheel

11.2.1.2.The Measure Reference Ratio

Figure 11-6:Chopped IR Signal

11.2.1.3.Summary Interference Rejection

GENERAL SAFETY HAZARD

11.3.PNEUMATIC OPERATION

maintenance schedule, Table

over ambient pressure

11.4.1.1.Critical Flow Orifice

11.4.FLOW RATE CONTROL

11.4.3.PNEUMATIC SENSORS

11.4.2.PARTICULATE FILTER

11.4.3.1.Sample Pressure Sensor

11.4.3.2.Sample Flow Sensor

11.5.1.OVERVIEW

11.5.ELECTRONIC OPERATION

Figure 11-9:M300E/EM Electronic Block Diagram

PC 104 Bus

MOTHER

BOARD

FLASH CHIP

11.5.2.CENTRAL PROCESSING UNIT CPU

DISK-ON-MODULEDOM

11.5.3.1.Temperature Control

11.5.3.OPTICAL BENCH & GFC WHEEL

11.5.3.2.IR Source

11.5.3.3.GFC Wheel

SEGMENT SENSOR

Figure 11-10:GFC Light Mask M/R SENSOR

Figure 11-11:Segment Sensor and M/R Sensor Output

SCHMIDT TRIGGERS

11.5.4.1.Overview

11.5.3.4.IR Photo-Detector

M300E/EM Sync/Demod Block Diagram

11.5.4.2.Signal Synchronization and Demodulation

Figure

Table 11-2:Sync DEMOD Sample and Hold Circuits

11.5.4.3.Sync/Demod Status LED’s

11.5.4.5.Dark Calibration Switch

11.5.4.4.Photo-DetectorTemperature Control

Figure 11-13:Sample & Hold Timing

11.5.5.RELAY BOARD

11.5.4.6.Electric Test Switch

11.5.5.1.Heater Control

11.5.5.2.GFC Wheel Motor Control

STATUS LED’s

RELAY PCA PN

11.5.5.5.Status LED’s

DC VOLTAGE TEST

11.5.6.1.A to D Conversion

11.5.6.MOTHERBOARD

11.5.6.2.Sensor Inputs

11.5.6.3.Thermistor Interface

11.5.6.5.Internal Digital I/O

11.5.6.4.Analog Outputs

11.5.6.6.External Digital I/O

BENCH TEMPERATURE SENSOR

11.5.7.I2C DATA BUS

11.5.8.POWER SUPPLY/ CIRCUIT BREAKER

POWER UP CIRCUIT

GENERAL SAFETY HAZARD

Theory of Operation

Figure 11-15:Power Distribution Block Diagram

Figure 11-16:Interface Block Diagram

11.5.9.COMMUNICATION INTERFACE

Mother

Board

11.5.10.1.Analyzer Status LED’s

11.5.10.FRONT PANEL INTERFACE

11.5.10.2.Keyboard

Figure 11-17:M300E/EM Front Panel Layout

11.5.10.4.Keyboard/Display Interface Electronics

11.5.10.3.Display

I2C Interface

2 x 40 CHAR. VACUUM FLUORESCENT DISPLAY

KEY-DEPRESS-DETECTCIRCUIT

KEYPAD DECODER

I2C INTERFACE CHIP

DISPLAY POWER WATCH DOG

DISPLAY DATA DECODER

DISPLAY CONTROLLER

Figure 11-19:Basic Software Operation

11.5.11.SOFTWARE OPERATION

11.5.12.ADAPTIVE FILTER

11.5.14.MEASUREMENT ALGORITHM

11.5.13.CALIBRATION - SLOPE AND OFFSET

11.5.15.TEMPERATURE AND PRESSURE COMPENSATION

11.5.16.INTERNAL DATA ACQUISITION SYSTEM IDAS

This page intentionally left blank

Theory of Operation

12.1.MAINTENANCE SCHEDULE

12.MAINTENANCE SCHEDULE & PROCEDURES

GENERAL SAFETY HAZARD

QUALIFIED PERSONNEL

Maintenance Schedule & Procedures

ACTION

ITEM

FREQ

CAL CHECK MANUAL REQ’D

Maintenance Schedule & Procedures

Table 12-3:Predictive uses for Test Functions

12.2.PREDICTING FAILURES USING THE TEST FUNCTIONS

FUNCTION

CONDITION

12.3.1.REPLACING THE SAMPLE PARTICULATE FILTER

12.3.MAINTENANCE PROCEDURES

12.3.2.REBUILDING THE SAMPLE PUMP

Figure 12-1:Sample Particulate Filter Assembly

12.3.3.1.Vacuum Leak Check and Pump Check

12.3.3.PERFORMING LEAK CHECKS

12.3.3.2.Pressure Leak Check

GENERAL SAFETY HAZARD

12.3.6.CLEANING EXTERIOR SURFACES OF THE M300E/EM

12.3.5.CLEANING THE OPTICAL BENCH

12.3.4.PERFORMING A SAMPLE FLOW CHECK

GENERAL SAFETY HAZARD

13.1.GENERAL TROUBLESHOOTING

13.TROUBLESHOOTING & REPAIR

GENERAL SAFETY HAZARD

QUALIFIED PERSONNEL

CLR SETUP

13.1.1.FAULT DIAGNOSIS WITH WARNING MESSAGES

SAMPLE

BENCH TEMP WARNING

Table 13-1 Warning Messages - Indicated Failures

13.1.2.FAULT DIAGNOSIS WITH TEST FUNCTIONS

PRES SAMPLE FL SAMP TEMP BENCH TEMP WHEEL TEMP

INDICATED FAILURES

BOX TEMP

Table 13-2:Test Functions - Indicated Failures

PHT DRIVE SLOPE OFFSET

INDICATED FAILURES

Figure 13-2:Example of Signal I/O Function

13.1.4.INTERNAL ELECTRONIC STATUS LED’S

13.1.4.1.CPU Status Indicator

Motherboard P/N

CPU Status LED Figure 13-3:CPU Status Indicator

13.1.4.2.Sync Demodulator Status LED’s

JP4 Connector to Opto-Pickup

D1 – M/R Sensor Status

Board

STATUS LED’s

RELAY PCA PN

DC VOLTAGE TEST

POINTS

Relay Board Status LED Failure Indications

Table

Figure 13-6:M300E/EM – Basic Internal Gas Flow

13.2.GAS FLOW PROBLEMS

13.2.1.M300E/EM INTERNAL GAS FLOW DIAGRAMS

Figure 13-7:Internal Pneumatic Flow OPT 50A – Zero/Span Valves OPT 50A & 50B

Figure 13-9:Internal Pneumatic Flow OPT 51B – Zero/Span Valves with Internal Zero Air Scrubber

Figure 13-11:M300E/EM – Internal Pneumatics with O2 Sensor Option

13.2.2.1.Flow is Zero

13.2.2.TYPICAL SAMPLE GAS FLOW PROBLEMS

13.2.2.2.Low Flow

13.2.2.3.High Flow

13.3.1.MISCALIBRATED

13.3.CALIBRATION PROBLEMS

13.2.2.4.Displayed Flow = “Warnings”

13.2.2.6.Sample Pump

13.3.4.INABILITY TO ZERO – NO ZERO KEY

13.3.2.NON-REPEATABLEZERO AND SPAN

13.3.3.INABILITY TO SPAN – NO SPAN KEY

13.4.1.TEMPERATURE PROBLEMS

13.4.OTHER PERFORMANCE PROBLEMS

13.4.1.1.Box or Sample Temperature

13.4.1.2.Bench Temperature

13.4.1.4.IR Photo-DetectorTEC Temperature

13.4.1.3.GFC Wheel Temperature

ELECTRICAL SHOCK HAZARD

Hazardous Voltages are present during this test

13.4.2.EXCESSIVE NOISE

13.5.2.DC POWER SUPPLY

13.5.1.AC MAINS CONFIGURATION

13.5.SUBSYSTEM CHECKOUT

DC Power Test Point and Wiring Color Codes

13.5.4.KEYBOARD/DISPLAY INTERFACE

13.5.3.I2C BUS

DC Power Supply Acceptable Levels

Table

Table 13-8:Relay Board Control Devices

13.5.5.RELAY BOARD

FUNCTION

CONTROL

13.5.6.2.Electrical Test

13.5.6.SENSOR ASSEMBLY

13.5.6.1.Sync/Demodulator Assembly

13.5.6.4.GFC Wheel Drive

13.5.6.3.Opto Pickup Assembly

13.5.6.5.IR Source

Table

13.5.6.6.Pressure/Flow Sensor Assembly

13.5.7.2.Test Channel / Analog Outputs Voltage

13.5.7.MOTHERBOARD

13.5.7.1.A/D Functions

13.5.7.3.Analog Outputs: Current Loop

Table 13-12:Status Outputs Check

13.5.7.4.Status Outputs

13.5.8.CPU

13.5.9.1.General RS-232Troubleshooting

13.5.9.RS-232COMMUNICATIONS

13.5.7.5.Control Inputs – Remote Zero, Span

13.5.10.THE OPTIONAL CO2 SENSOR

13.6.1.REPAIRING SAMPLE FLOW CONTROL ASSEMBLY

13.6.REPAIR PROCEDURES

Figure 13-15:Opening the GFC Wheel Housing

13.6.2.REMOVING/REPLACING THE GFC WHEEL

Opto-Pickup

Figure 13-16:Removing the Opto-PickupAssembly

Figure 13-17:Removing the GFC Wheel Housing

Figure 13-18:Removing the GFC Wheel

Optical Bench

VR1 Adjustment Made Here

Housing Mounting Screws Sync/Demod PCA Housing

13.7.TECHNICAL ASSISTANCE

13.6.4.DISK-ON-MODULEREPLACEMENT PROCEDURE

Teledyne API, Customer Service

9480 Carroll Park Drive

Figure 14-1:Triboelectric Charging

14.A PRIMER ON ELECTRO-STATICDISCHARGE

14.1.HOW STATIC CHARGES ARE CREATED

14.2.HOW ELECTRO-STATICCHARGES CAUSE DAMAGE

14.4.BASIC PRINCIPLES OF STATIC CONTROL

14.3.COMMON MYTHS ABOUT ESD DAMAGE

14.4.1.GENERAL RULES

Figure 14-2:Basic anti-ESDWorkbench

Always wear an Anti-ESDwrist strap when working on the electronic assemblies of your analyzer. An anti-ESDwrist strap keeps the person wearing it at or near the same potential as other grounded objects in the work area and allows static charges to dissipate before they can build to dangerous levels. Anti-ESDwrist straps terminated with alligator clips are available for use in work areas where there is no available grounded plug

14.4.2.2.Working at an Anti-ESDWork Bench

14.4.2.1.Working at the Instrument Rack

4.Place the item in the container

∙DO NOT use pink-polybags

ESD Hazard

CAUTION – Avoid Warranty Invalidation

This page intentionally left blank

A Primer on Electro-StaticDischarge

Page

Page

Page

Page

Page

Page

Warnings,

This page intentionally left blank

Technical Manual - Model 300E Family CO Analyzers

APPENDIX A-1:SOFTWARE MENU TREES, REVISION L.8

MSG1

SAMPLE

TEST1

RNGE PASS

SAMPLE SETUP

CLK MORE

<TST TST>

ACAL1

Figure A-3:Primary Setup Menu DAS Submenu

APPENDIX A-1:Software Menu Trees, Revision L.8

APPENDIX A-1:Software Menu Trees, Revision L.8

O2, 312 REPORTED

SAMPLESETUP

CO, 310, REPORTED CO2, 311, REPORTED

APPENDIX A-1:Software Menu Trees, Revision L.8

Figure A-6:DIAG Menu A-7

Default Value

Setup Variable

Numeric Units

Value Range

Numeric

Default

Value

Units

Default

Setup Variable

APPENDIX A-2:Setup Variables For Serial I/O

Numeric

Default

Setup Variable

Numeric

Value

Default

Setup Variable

APPENDIX A-2:Setup Variables For Serial I/O

Numeric

Default

Setup Variable

Numeric

Value

Default

Setup Variable

Same settings as

Numeric

Default

Setup Variable

Numeric

Value

Default

Setup Variable

APPENDIX A-2:Setup Variables For Serial I/O

Numeric

Default

Setup Variable

Numeric

Value

Default

Setup Variable

APPENDIX A-2:Setup Variables For Serial I/O

Numeric

Default

Setup Variable

Numeric

Value

Default

Setup Variable

APPENDIX A-2 Setup Variables For Serial I/O

Numeric

Message Text

Name

Description

APPENDIX A-3:Warnings and Test Functions

Message Text

Name

Description

A-22

TEST FUNCTION NAME

A-23

MESSAGE TEXT

DESCRIPTION

STABIL_SAMPLES

A-24

APPENDIX A-3 Warnings and Test Functions

TEST FUNCTION NAME

A-25

MESSAGE TEXT

DESCRIPTION

Bit or Channel Number

Signal Name

APPENDIX A-4:Signal I/O Definitions

APPENDIX A-4:Signal I/O Definitions

Bit or Channel Number

Signal Name

Description

A-27

Number

Bit or Channel

Signal Name

Description

Bit or Channel Number

Signal Name

Description

A-29

APPENDIX A-4:Signal I/O Definitions

Signal Name

Bit or Channel Number

Description

Description

Name

APPENDIX A-5:DAS Triggers and Parameters

A-31

Description

Name

Units

A-32

Description

Name

Units

A-33

Table A-7:Terminal Command Designators

APPENDIX A-6:Terminal Command Designators

APPENDIX A-6:Terminal Command Designators

COMMAND

Register Address

MODBUS

dec., 0-based

MODBUS Floating Point Input Registers

MODBUS

MODBUS Floating Point Holding Registers

Description

Units

single-bit; read-only

MODBUS Discrete Input Registers

MODBUS

Description

single-bit;read/write

MODBUS Coil Registers

MODBUS

Description

04288D DCN5752

APPENDIX B - Spare Parts

This page intentionally left blank

Description

M300E Spare Parts List

Part Number

Reference: 05362J DCN5494

M300E Spare Parts List

Part Number

Description

Description

M300EM Spare Parts List

Part Number

Reference: 05424H DCN5494

M300EM Spare Parts List

Part Number

Description

6-10

M300EM Recommended Spare Parts Stocking Levels

11-20

21-30

Reference: 0096004C

M300E/EX Expendables Kit

ORIFICE, 13 MIL SAMPLE FLOW

000941000

009550500

ASSY, SOURCE

009560301

T300/T300M and M300E/EM

APPENDIX C Warranty/Repair Questionnaire

Email: api-customerservice@teledyne.com

Please complete the following table

Email: api-customerservice@teledyne.com

APPENDIX C Warranty/Repair Questionnaire

T300/T300M and M300E/EM

2v/DIV

04288D DCN5752

APPENDIX D – Wire List and Electronic Schematics

04288D DCN5752

This page intentionally left blank

Interconnect List, M300E/EU, SNs 100 and greater

FROM

FROM

This page intentionally left blank

Page

Sync Demod Page 1 03297k_1.sch

D C B A

Sync Demod Page 2 03297k_2.sch

Sync Demod Page 3 03297k_3.sch

Schematics for PCA 03296, Sync Demod

1. This schematics is for PCA

Signal

proper authorization

PREAMP_ENAB

Schematics for PCA 03296, Sync Demod

TV_ENAB

SYNC_10

proper authorization

Schematics for PCA 03296, Sync Demod

BIAS SUPPLY

17-Sep-2008

03632

PCA 03631, Isolated 0-20ma,E Series

19-Jul-2002

1 of

NOTES

1. This schematic is based on the

PWB PN, 03974 and applies to

PCA PN,

+15V

+15V

+15V

+15V

05703

ADDR=0x360 DEFAULT

Schematic for E Series Motherboard PCA

05703

TX for Com1

RX for Com2

+15V

J109

+15V

CONTROL INPUTS

D2 D3 D4 D5 D6 D7

SHDN

OPTO-INTERRUPTER

Schematics for PWB

and PCA

BENCH

Schematic, PCA 04135 Revision A, M300E Relay PCA

SPARE

NOTE: 1. Use PWB

NOTES

1. This schematic is based on

applies to PCA PN,

the PWB PN, 03974 and

04468

SCH, E-SeriesAnalog Output Isolator, PCA

1 A B C D 1

Not Used