Chapter 2 Installation and Wiring![]()

![]() CAUTION!

CAUTION!

1.The wiring of main circuit and control circuit should be separated to prevent erroneous actions.

2.Please use shield wire for the control wiring and not to expose the

3.Please use the shield wire or tube for the power wiring and ground the two ends of the shield wire or tube.

4.Damaged insulation of wiring may cause personal injury or damage to circuits/equipment if it comes in contact with high voltage.

5.The AC motor drive, motor and wiring may cause interference. To prevent the equipment damage, please take care of the erroneous actions of the surrounding sensors and the equipment.

6.When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor terminals U/T1, V/T2, and W/T3, respectively. To permanently reverse the direction of motor rotation, switch over any of the two motor leads.

7.With long motor cables, high capacitive switching current peaks can cause

8.The AC motor drive, electric welding machine and the greater horsepower motor should be grounded separately.

9.Use ground leads that comply with local regulations and keep them as short as possible.

10.No brake resistor is built in the

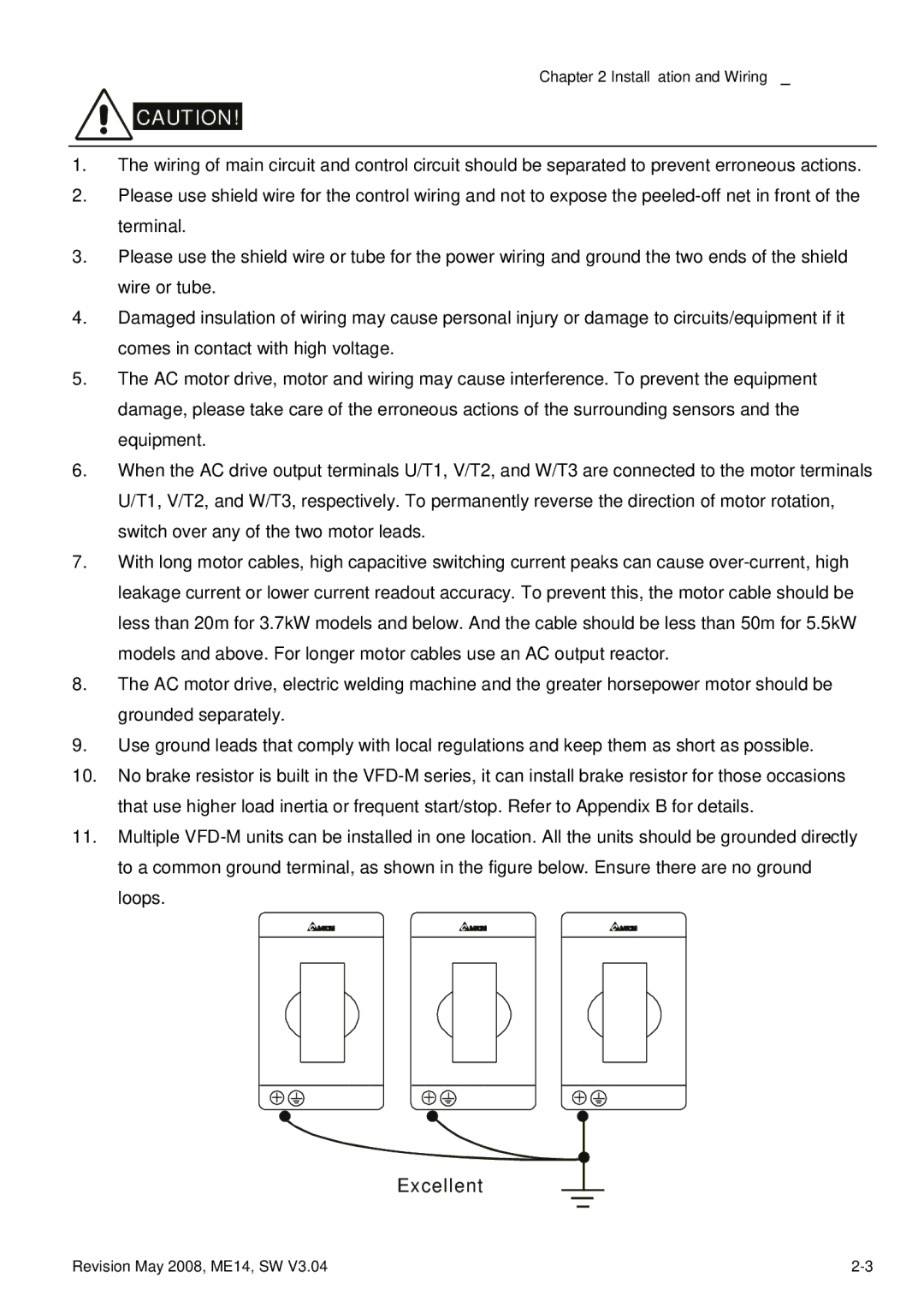

11.Multiple

Excellent

Revision May 2008, ME14, SW V3.04 |