Return to Master TOC

TROUBLESHOOTING AND REPAIR |

CURRENT TRANSDUCER TEST (continued)

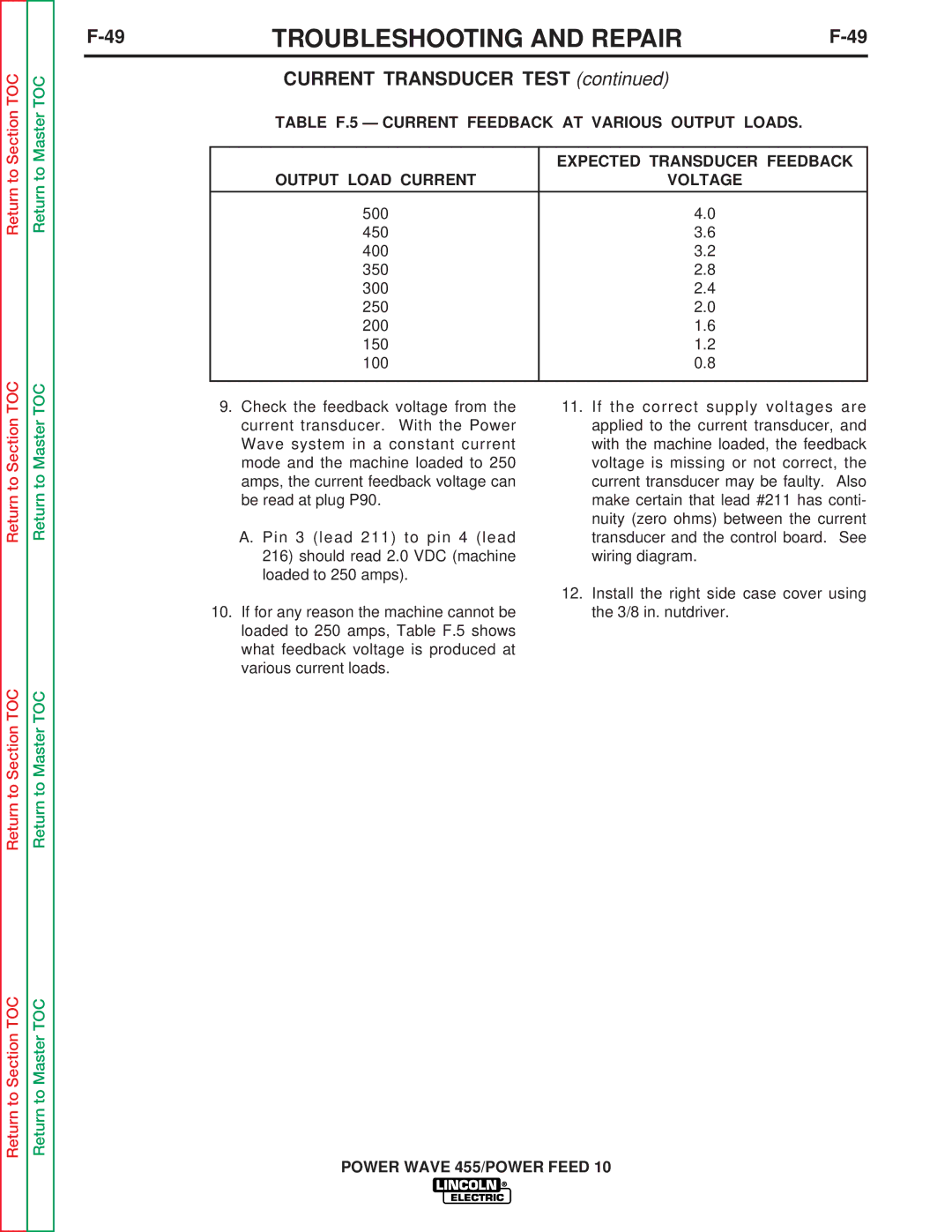

TABLE F.5 — CURRENT FEEDBACK AT VARIOUS OUTPUT LOADS.

| EXPECTED TRANSDUCER FEEDBACK |

OUTPUT LOAD CURRENT | VOLTAGE |

|

|

500 | 4.0 |

450 | 3.6 |

400 | 3.2 |

350 | 2.8 |

300 | 2.4 |

250 | 2.0 |

200 | 1.6 |

150 | 1.2 |

100 | 0.8 |

|

|

Return to Master TOC

Return to Master TOC

Return to Master TOC

9.Check the feedback voltage from the current transducer. With the Power Wave system in a constant current mode and the machine loaded to 250 amps, the current feedback voltage can be read at plug P90.

A.Pin 3 (lead 211) to pin 4 (lead 216) should read 2.0 VDC (machine loaded to 250 amps).

10.If for any reason the machine cannot be loaded to 250 amps, Table F.5 shows what feedback voltage is produced at various current loads.

11.If the correct supply voltages are applied to the current transducer, and with the machine loaded, the feedback voltage is missing or not correct, the current transducer may be faulty. Also make certain that lead #211 has conti- nuity (zero ohms) between the current transducer and the control board. See wiring diagram.

12.Install the right side case cover using the 3/8 in. nutdriver.