Return to Section TOC

TOC

Return to Master TOC

TOC

| INSTALLATION |

|

| ||||

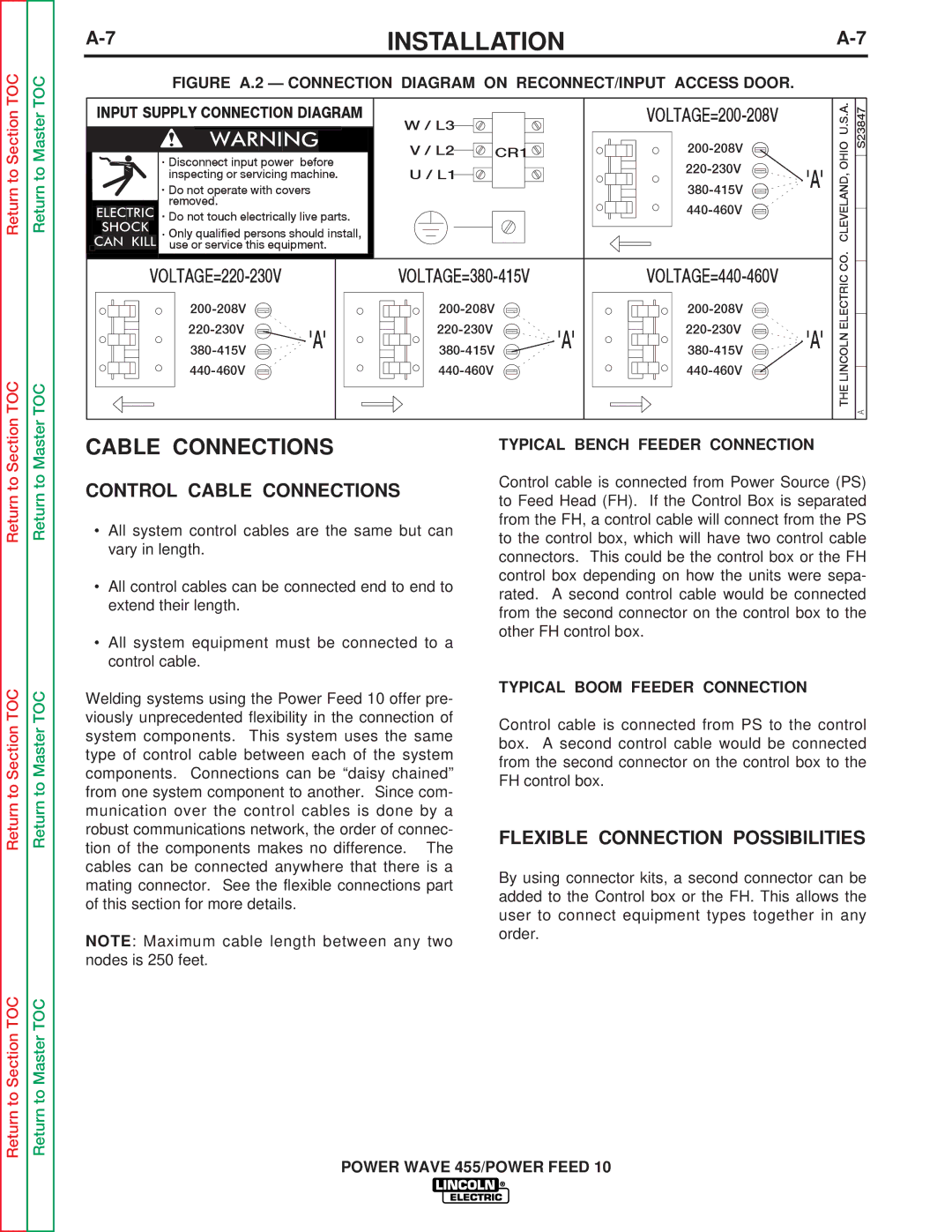

| FIGURE A.2 — CONNECTION DIAGRAM ON RECONNECT/INPUT ACCESS DOOR. |

| OHIOU.S.A. | S23847 | |||

. | Disconnect input power before |

|

|

|

| ||

INPUT SUPPLY CONNECTION DIAGRAM | W / L3 |

|

|

|

| ||

|

|

|

|

|

|

| |

|

| V / L2 | CR1 |

|

|

| |

| inspecting or servicing machine. | U / L1 |

| 'A' | CLEVELAND, |

| |

. |

|

| |||||

Only qualified persons should install, |

|

|

| ||||

. | Do not operate with covers |

|

|

|

| ||

| removed. |

|

|

|

|

| |

. Do not touch electrically live parts. |

|

|

|

|

| ||

| use or service this equipment. |

|

|

|

|

|

|

|

| CO. | |||

|

| ELECTRIC | |||

|

| ||||

|

|

| |||

'A' | 'A' | 'A' | |||

|

| LINCOLNTHE | |||

|

|

|

A

Return to Section

Return to Section TOC

Return to Section TOC

Return to Master

Return to Master TOC

Return to Master TOC

CABLE CONNECTIONS

CONTROL CABLE CONNECTIONS

•All system control cables are the same but can vary in length.

•All control cables can be connected end to end to extend their length.

•All system equipment must be connected to a control cable.

Welding systems using the Power Feed 10 offer pre- viously unprecedented flexibility in the connection of system components. This system uses the same type of control cable between each of the system components. Connections can be “daisy chained” from one system component to another. Since com- munication over the control cables is done by a robust communications network, the order of connec- tion of the components makes no difference. The cables can be connected anywhere that there is a mating connector. See the flexible connections part of this section for more details.

NOTE: Maximum cable length between any two nodes is 250 feet.

TYPICAL BENCH FEEDER CONNECTION

Control cable is connected from Power Source (PS) to Feed Head (FH). If the Control Box is separated from the FH, a control cable will connect from the PS to the control box, which will have two control cable connectors. This could be the control box or the FH control box depending on how the units were sepa- rated. A second control cable would be connected from the second connector on the control box to the other FH control box.

TYPICAL BOOM FEEDER CONNECTION

Control cable is connected from PS to the control box. A second control cable would be connected from the second connector on the control box to the FH control box.

FLEXIBLE CONNECTION POSSIBILITIES

By using connector kits, a second connector can be added to the Control box or the FH. This allows the user to connect equipment types together in any order.

POWER WAVE 455/POWER FEED 10