OPERATION |

Return to Master TOC

Return to Master TOC

Return to Master TOC

Light |

|

Condition | Meaning |

Steady Green | System OK. Power source communicating |

| normally with wire feeder and its |

| components. |

|

|

Blinking | Nothing connected to Wire Feeder |

Green | Receptacle. |

|

|

Alternating | Recoverable system fault. See |

Green and | Troubleshooting Section. |

Red |

|

|

|

Steady Red | |

| power source off, find source of error, and |

| turn power back on to reset. See |

| Troubleshooting Section. |

|

|

Blinking Red | See Troubleshooting Section. |

|

|

3.HIGH TEMPERATURE LIGHT (thermal overload): A yellow light that comes on when an over tem- perature situation occurs. Output is disabled until the machine cools down. When cool, the light goes out and output is enabled.

4.10 AMP WIRE FEEDER CIRCUIT BREAKER: Protects 40 volt DC wire feeder power supply.

5.10 AMP AUXILIARY POWER CIRCUIT BREAK- ER: Protects 115 volt AC receptacle.

POWER FEED CONTROLS

1. 2-STEP/4-STEP SWITCH OPERATION

The Power Feed head unit has a

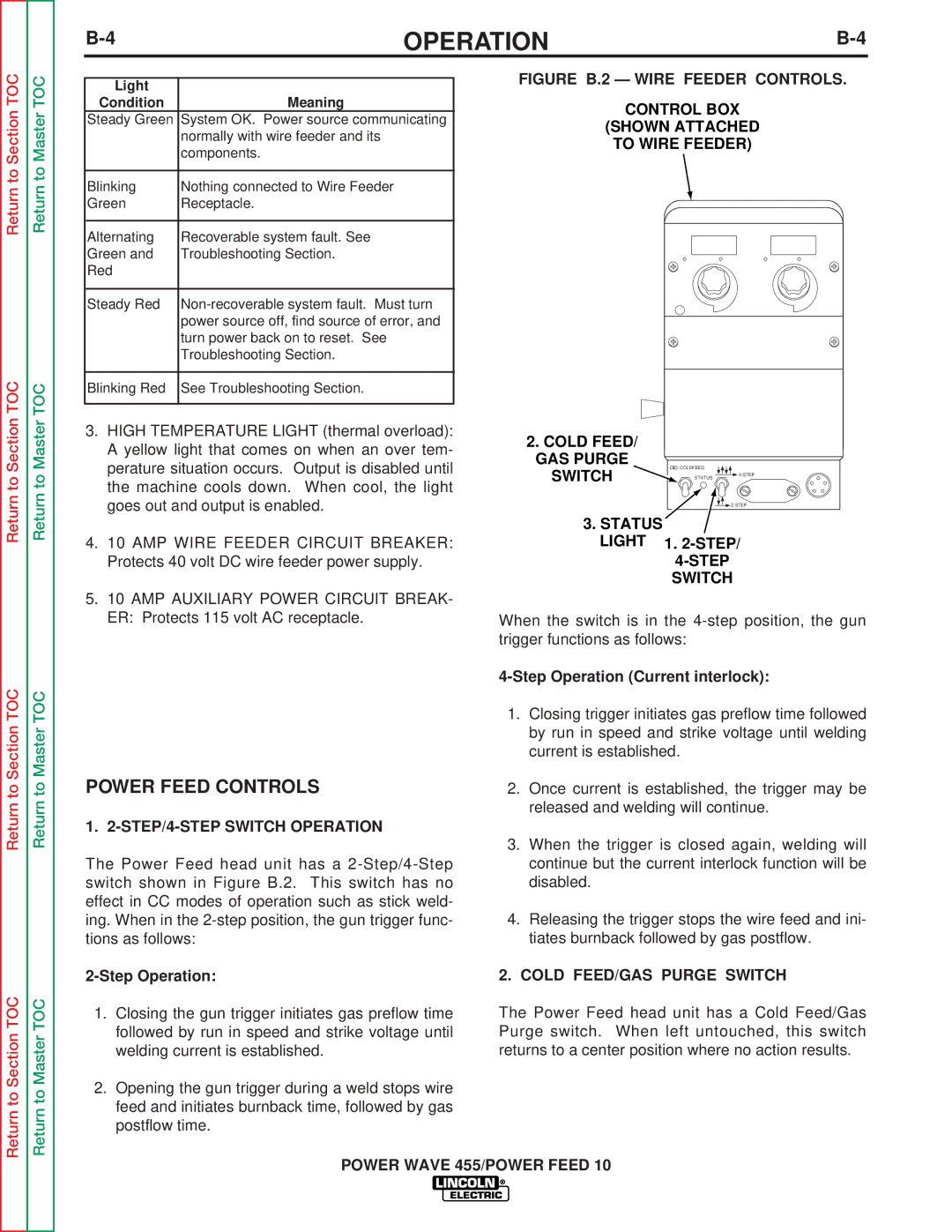

FIGURE B.2 — WIRE FEEDER CONTROLS.

CONTROL BOX

(SHOWN ATTACHED

TO WIRE FEEDER)

2. COLD FEED/ |

|

|

GAS PURGE | COLDFEED |

|

SWITCH |

| |

STATUS | ||

|

|

![]() 2-STEP

2-STEP

3.STATUS

LIGHT 1. 2-STEP/ 4-STEP SWITCH

When the switch is in the

4-Step Operation (Current interlock):

1.Closing trigger initiates gas preflow time followed by run in speed and strike voltage until welding current is established.

2.Once current is established, the trigger may be released and welding will continue.

3.When the trigger is closed again, welding will continue but the current interlock function will be disabled.

4.Releasing the trigger stops the wire feed and ini- tiates burnback followed by gas postflow.

2. COLD FEED/GAS PURGE SWITCH |

Return to Master TOC

1.Closing the gun trigger initiates gas preflow time followed by run in speed and strike voltage until welding current is established.

2.Opening the gun trigger during a weld stops wire feed and initiates burnback time, followed by gas postflow time.

The Power Feed head unit has a Cold Feed/Gas Purge switch. When left untouched, this switch returns to a center position where no action results.

POWER WAVE 455/POWER FEED 10