Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

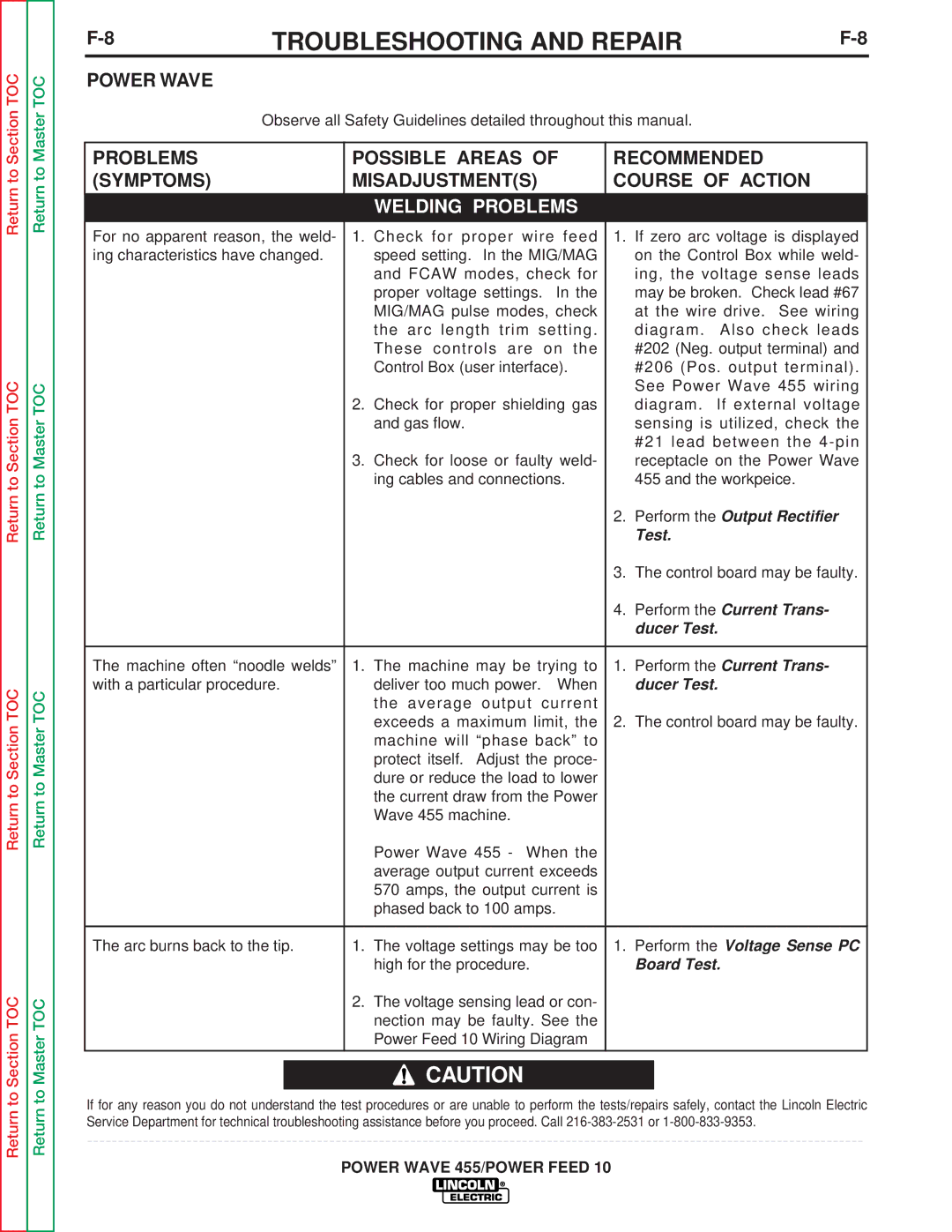

TROUBLESHOOTING AND REPAIR |

POWER WAVE

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | ||||

(SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION | |||

|

|

|

|

|

| |

|

| WELDING PROBLEMS |

|

|

| |

|

|

|

| |||

For no apparent reason, the weld- | 1. | Check for proper wire feed | 1. If zero arc voltage is displayed | |||

ing characteristics have changed. |

| speed setting. In the MIG/MAG |

| on the Control Box while weld- | ||

|

| and FCAW modes, check for |

| ing, the voltage sense leads | ||

|

| proper voltage settings. | In the |

| may be broken. Check lead #67 | |

|

| MIG/MAG pulse modes, check |

| at the wire drive. See wiring | ||

|

| the arc length trim setting. |

| diagram. | Also check leads | |

|

| These controls are on the |

| #202 (Neg. output terminal) and | ||

|

| Control Box (user interface). |

| #206 (Pos. output terminal). | ||

|

|

|

|

| See Power Wave 455 wiring | |

| 2. | Check for proper shielding gas |

| diagram. | If external voltage | |

|

| and gas flow. |

|

| sensing is utilized, check the | |

|

|

|

|

| #21 lead between the | |

| 3. | Check for loose or faulty weld- |

| receptacle on the Power Wave | ||

|

| ing cables and connections. |

| 455 and the workpeice. | ||

|

|

|

| 2. Perform the Output Rectifier | ||

|

|

|

|

| Test. |

|

|

|

|

| 3. The control board may be faulty. | ||

|

|

|

| 4. Perform the Current Trans- | ||

|

|

|

|

| ducer Test. | |

|

|

|

| |||

The machine often “noodle welds” | 1. | The machine may be trying to | 1. Perform the Current Trans- | |||

with a particular procedure. |

| deliver too much power. | When |

| ducer Test. | |

|

| the average output current |

|

|

| |

|

| exceeds a maximum limit, the | 2. | The control board may be faulty. | ||

|

| machine will “phase back” to |

|

|

| |

|

| protect itself. Adjust the proce- |

|

|

| |

|

| dure or reduce the load to lower |

|

|

| |

|

| the current draw from the Power |

|

|

| |

|

| Wave 455 machine. |

|

|

|

|

|

| Power Wave 455 - When the |

|

|

| |

|

| average output current exceeds |

|

|

| |

|

| 570 amps, the output current is |

|

|

| |

|

| phased back to 100 amps. |

|

|

|

|

|

|

|

|

| ||

The arc burns back to the tip. | 1. | The voltage settings may be too | 1. | Perform the Voltage Sense PC | ||

|

| high for the procedure. |

|

| Board Test. | |

| 2. | The voltage sensing lead or con- |

|

|

| |

|

| nection may be faulty. See the |

|

|

| |

|

| Power Feed 10 Wiring Diagram |

|

|

| |

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call