Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

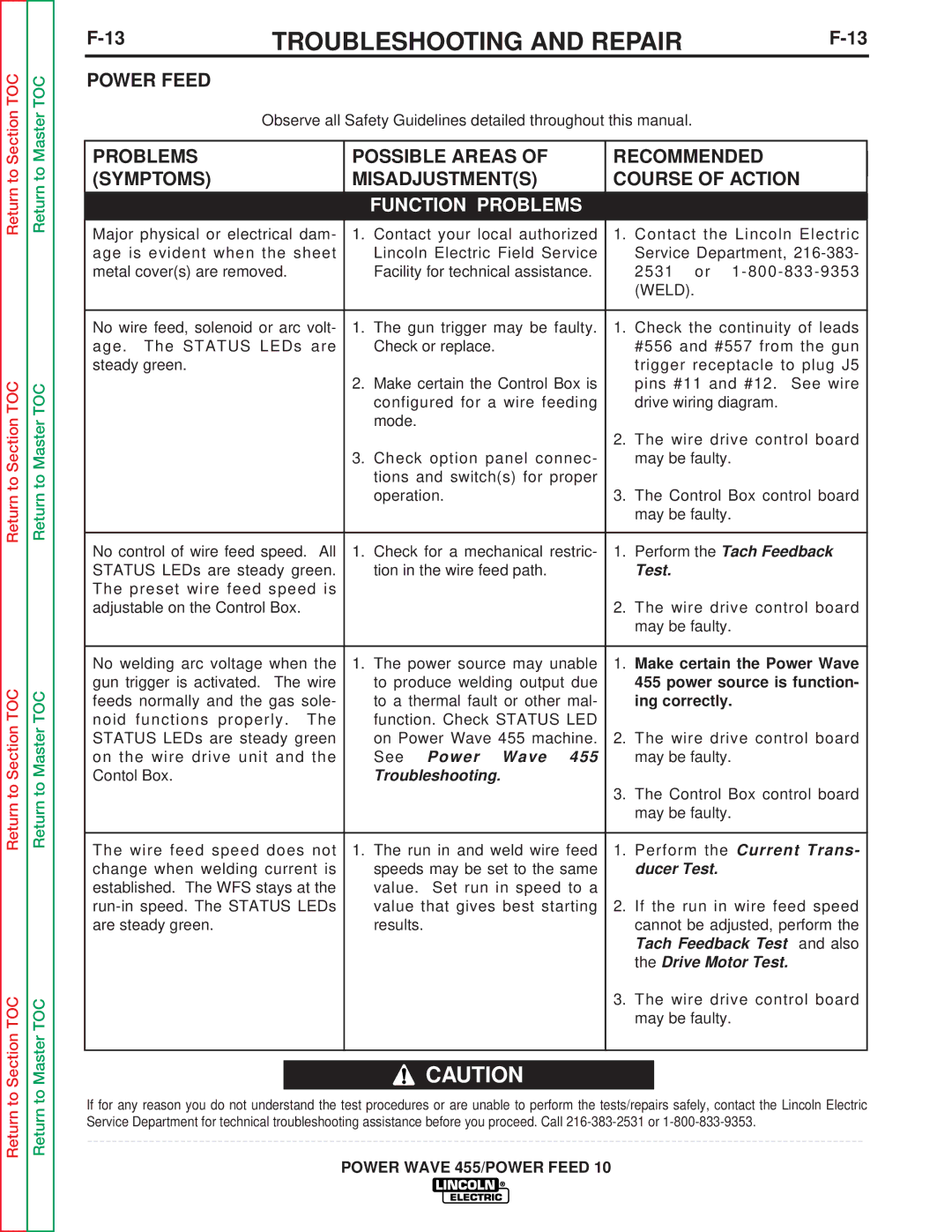

TROUBLESHOOTING AND REPAIR |

POWER FEED

Observe all Safety Guidelines detailed throughout this manual.

PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |||

(SYMPTOMS) | MISADJUSTMENT(S) | COURSE OF ACTION | |||

|

|

|

|

| |

|

| FUNCTION PROBLEMS |

|

| |

|

|

|

| ||

Major physical or electrical dam- | 1. Contact your local authorized | 1. | Contact the Lincoln Electric | ||

age is evident when the sheet | Lincoln Electric Field Service |

| Service Department, | ||

metal cover(s) are removed. | Facility for technical assistance. |

| 2531 or | ||

|

|

|

|

| (WELD). |

|

|

|

| ||

No wire feed, solenoid or arc volt- | 1. The gun trigger may be faulty. | 1. | Check the continuity of leads | ||

age. | The STATUS LEDs are | Check or replace. |

| #556 and #557 from the gun | |

steady green. |

|

|

| trigger receptacle to plug J5 | |

|

| 2. Make certain the Control Box is |

| pins #11 and #12. See wire | |

|

| configured for a wire feeding |

| drive wiring diagram. | |

|

| mode. |

|

|

|

|

|

|

| 2. | The wire drive control board |

|

| 3. Check option panel connec- |

| may be faulty. | |

|

| tions and switch(s) for proper |

|

| |

|

| operation. | 3. | The Control Box control board | |

|

|

|

|

| may be faulty. |

|

|

|

| ||

No control of wire feed speed. All | 1. Check for a mechanical restric- | 1. | Perform the Tach Feedback | ||

STATUS LEDs are steady green. | tion in the wire feed path. |

| Test. | ||

The preset wire feed speed is |

|

|

|

| |

adjustable on the Control Box. |

|

| 2. | The wire drive control board | |

|

|

|

|

| may be faulty. |

|

|

|

| ||

No welding arc voltage when the | 1. The power source may unable | 1. | Make certain the Power Wave | ||

gun trigger is activated. The wire | to produce welding output due |

| 455 power source is function- | ||

feeds normally and the gas sole- | to a thermal fault or other mal- |

| ing correctly. | ||

noid | functions properly. The | function. Check STATUS LED |

|

| |

STATUS LEDs are steady green | on Power Wave 455 machine. | 2. | The wire drive control board | ||

on the wire drive unit and the | See | Power Wave 455 |

| may be faulty. | |

Contol Box. | Troubleshooting. |

|

| ||

|

|

|

| 3. | The Control Box control board |

|

|

|

|

| may be faulty. |

|

|

|

| ||

The wire feed speed does not | 1. The run in and weld wire feed | 1. | Perform the Current Trans- | ||

change when welding current is | speeds may be set to the same |

| ducer Test. | ||

established. The WFS stays at the | value. | Set run in speed to a |

|

| |

value that gives best starting | 2. | If the run in wire feed speed | |||

are steady green. | results. |

|

| cannot be adjusted, perform the | |

|

|

|

|

| Tach Feedback Test and also |

|

|

|

|

| the Drive Motor Test. |

|

|

|

| 3. | The wire drive control board |

|

|

|

|

| may be faulty. |

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call