OPERATION |

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

WIRE SPINDLE PLACEMENT

The reel stand provides two mounting locations for the 2 inch diameter wire reel spindle to accommo- date various reel sizes. Each mounting location con- sists of a tube in the center of the reel stand, and a locating pin on the right side (viewed from the front) of the reel stand. The bolt, used with a plain washer and lock washer, slides through the tube from the left side of the reel stand. The large plain washer is placed between the wire spindle hub and the reel stand. The bolt should be threaded into the wire spindle such that the locating pin aligns with the largest of the three holes (the hole that is not recessed) in the back side of the wire spindle base.

The upper location must be used for 50 to 60 lb

For smaller coils (44 lb, 30 lb, 10 lb, etc.), the spindle can be placed in either the upper or lower location. The goal is to make the wire path from the coil to the incoming wire guide as straight as possible. This will optimize wire feeding performance.

WIRE REEL LOADING -

READI-REELS, SPOOLS

OR COILS

TO MOUNT A 30 LB (14 KG) READI-

REEL PACKAGE (USING THE MOLDED PLASTIC

The spindle should be located in the LOWER mount- ing hole.

1.Depress the release bar on the retaining collar and remove it from the spindle.

2.Place the adapter on the spindle.

3.

4.Rotate the spindle and adapter so the retaining spring is at the 12 o'clock position.

5.Position the

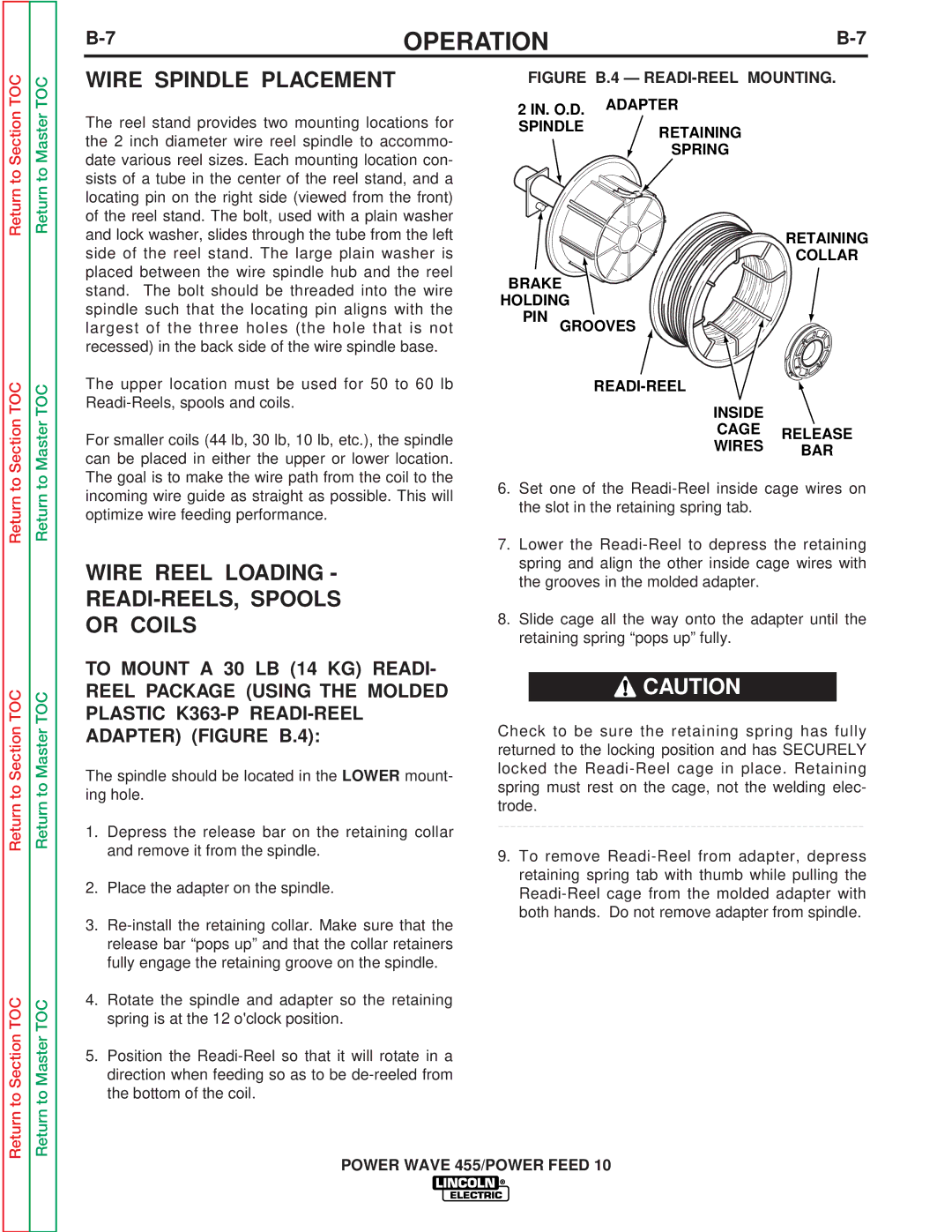

FIGURE B.4 — READI-REEL MOUNTING.

2 IN. O.D. ADAPTER

SPINDLE  RETAINING SPRING

RETAINING SPRING

RETAINING

COLLAR

BRAKE HOLDING

PIN GROOVES

INSIDE

CAGE RELEASE

WIRES BAR

6.Set one of the

7.Lower the

8.Slide cage all the way onto the adapter until the retaining spring “pops up” fully.

![]() CAUTION

CAUTION

Check to be sure the retaining spring has fully returned to the locking position and has SECURELY locked the

9.To remove

POWER WAVE 455/POWER FEED 10