OPERATION |

Return to Section TOC

Return to Section TOC

Cold feed function:

When this switch is held in the up position, the unit automatically feeds wire, but does not activate output to the power source or gas solenoid. The speed of this cold feed is factory preset to 200 IPM. It can be adjusted while the switch is held up, by rotating the WFS encoder knob on the Control Box. Note that this cold feed speed is independent of WFS or run in speeds. When the cold feed switch is released, the cold feed value is memorized for the next time cold feed is activated.

Gas purge function:

When this switch is held in the down position only the gas solenoid valve is energized.

3. STATUS LIGHT

A two color light that indicates system errors. Normal operation is a steady green light.

1. Indicator Lights:

Indicates either WFS or AMPS for the left display, and VOLTS or TRIM for the right display.

2. Displays:

Two extra bright, 3 1/2 digit, red LED displays. The values of the active parameters are displayed, as defined by their associated indicators. The left dis- play is for WFS or Amps, while the right display is for voltage or trim.

3. Left Encoder-Wire Feed Speed or Output Amps:

The left encoder is used to adjust the parameters for either wire feed speed or output amps, dependent upon the process and weld mode being used. Rotating the encoder knob CCW decreases the num- ber value, while rotating the knob CW increases the number value. The ranges and limits are as follows:

WFS - Low Range: 50 to 800 IPM (1.25 to 19.99 MPM) High Range: 75 to 1200 IPM (2.0 to 30.5 MPM)

Return to Master TOC

Return to Master TOC

Return to Master TOC

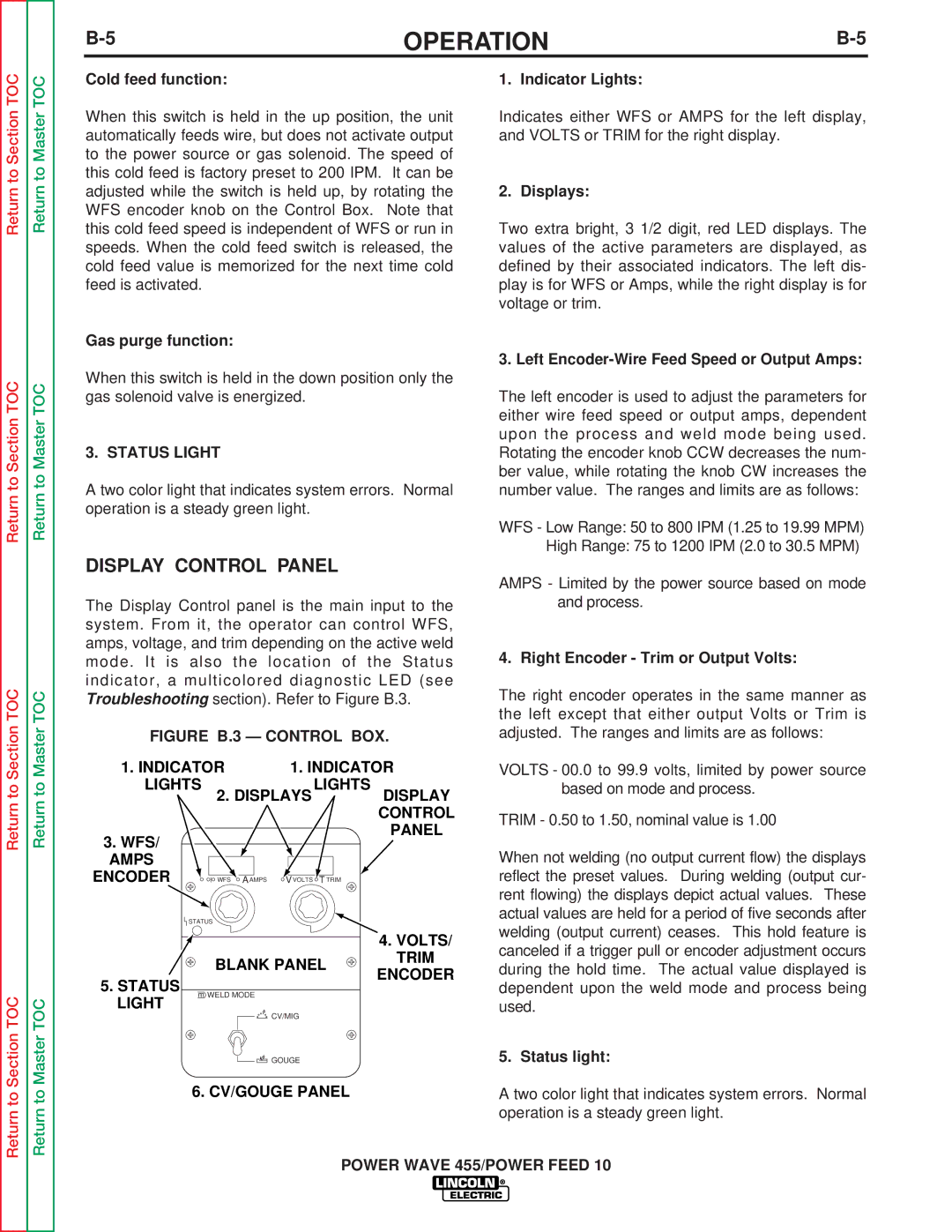

DISPLAY CONTROL PANEL

The Display Control panel is the main input to the system. From it, the operator can control WFS, amps, voltage, and trim depending on the active weld mode. It is also the location of the Status indicator, a multicolored diagnostic LED (see Troubleshooting section). Refer to Figure B.3.

FIGURE B.3 — CONTROL BOX.

1. INDICATOR | 1. INDICATOR | |

LIGHTS |

| LIGHTS |

2. DISPLAYS | DISPLAY | |

CONTROL

PANEL

3.WFS/

AMPS

ENCODER | WFS AAMPS VVOLTS T TRIM |

![]()

![]() STATUS

STATUS

4. VOLTS/

BLANK PANEL  TRIM ENCODER

TRIM ENCODER

5. STATUS

AMPS - Limited by the power source based on mode and process.

4. Right Encoder - Trim or Output Volts:

The right encoder operates in the same manner as the left except that either output Volts or Trim is adjusted. The ranges and limits are as follows:

VOLTS - 00.0 to 99.9 volts, limited by power source based on mode and process.

TRIM - 0.50 to 1.50, nominal value is 1.00

When not welding (no output current flow) the displays reflect the preset values. During welding (output cur- rent flowing) the displays depict actual values. These actual values are held for a period of five seconds after welding (output current) ceases. This hold feature is canceled if a trigger pull or encoder adjustment occurs during the hold time. The actual value displayed is dependent upon the weld mode and process being

Section TOC

Master TOC

LIGHT

m WELD MODE

CV/MIG

![]()

![]() GOUGE

GOUGE

used.

5. Status light:

Return to

Return to

6. CV/GOUGE PANEL

A two color light that indicates system errors. Normal operation is a steady green light.

POWER WAVE 455/POWER FEED 10