Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING AND REPAIR | |||||

| CONTROL CABLE CONTINUITY TEST (continued) |

| |||

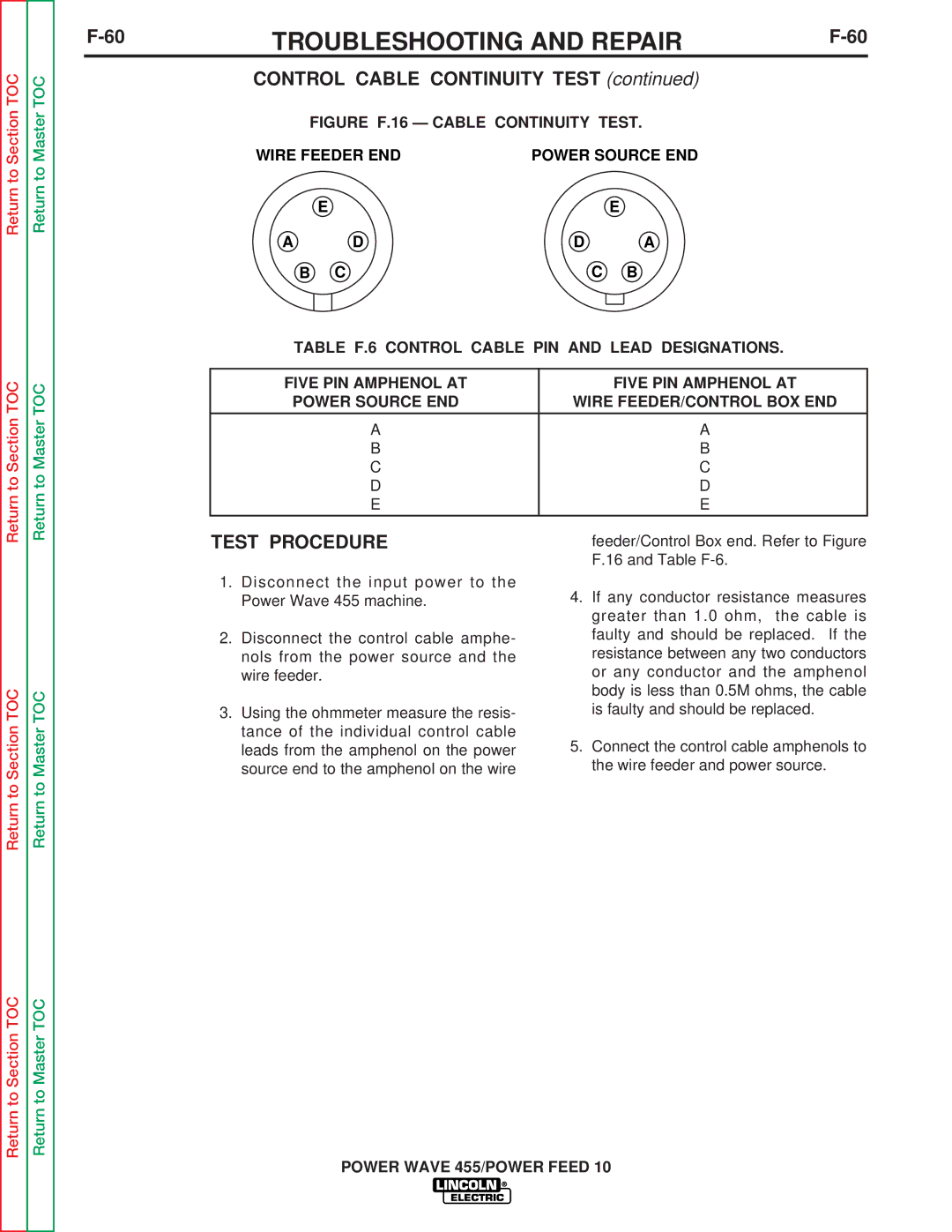

| FIGURE F.16 — CABLE CONTINUITY TEST. |

| |||

| WIRE FEEDER END | POWER SOURCE END |

| ||

|

| E |

| E |

|

| A | D | D | A |

|

| B | C | C | B |

|

TABLE F.6 CONTROL CABLE PIN AND LEAD DESIGNATIONS.

FIVE PIN AMPHENOL AT | FIVE PIN AMPHENOL AT |

POWER SOURCE END | WIRE FEEDER/CONTROL BOX END |

|

|

A | A |

B | B |

C | C |

D | D |

E | E |

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

TEST PROCEDURE

1.Disconnect the input power to the Power Wave 455 machine.

2.Disconnect the control cable amphe- nols from the power source and the wire feeder.

3.Using the ohmmeter measure the resis- tance of the individual control cable leads from the amphenol on the power source end to the amphenol on the wire

feeder/Control Box end. Refer to Figure F.16 and Table

4.If any conductor resistance measures greater than 1.0 ohm, the cable is faulty and should be replaced. If the resistance between any two conductors or any conductor and the amphenol body is less than 0.5M ohms, the cable is faulty and should be replaced.

5.Connect the control cable amphenols to the wire feeder and power source.